A kind of preparation method of high specific capacity porous silicon oxide compound

An oxygen compound, high specific capacity technology, used in silicon oxide, electrical components, battery electrodes, etc., can solve the problems of wasting silicon monoxide raw materials and hydrofluoric acid, lack of nano-silicon, low initial efficiency, etc., to reduce volume expansion. effect, uniform particle distribution, high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

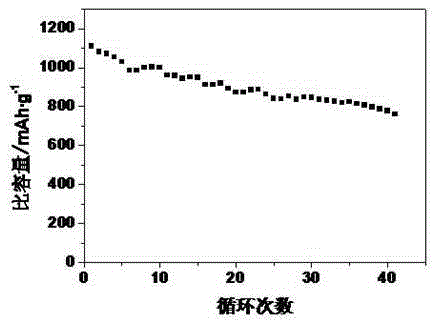

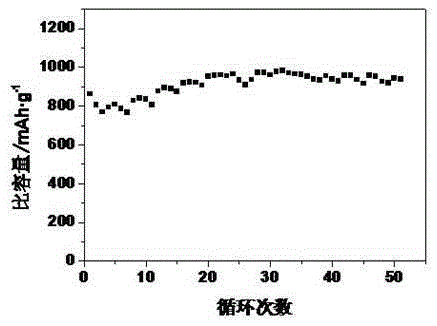

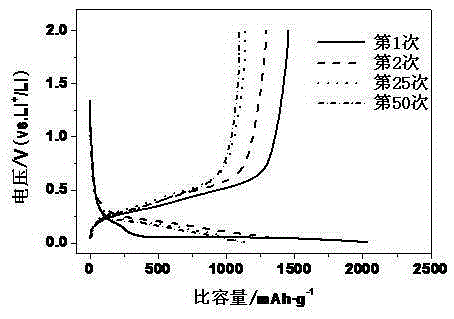

[0026] Put 4.4g of silicon monoxide particles into the corundum ark, put the corundum ark into the tube furnace, turn on the mechanical pump, and after evacuating to 5Pa, turn on the molecular pump and evacuate to 10 -2 Pa. Raise the temperature at 10°C per minute to 1000°C, keep the temperature for 8 hours, and cool down to room temperature with the furnace. During this process, part of the silicon monoxide disproportionates to form silicon nanoparticles.

[0027] Place the prepared product in a plastic beaker, add 40ml of hydrofluoric acid aqueous solution with a mass fraction of 10%, stir for 10 minutes, and ultrasonically corrode for 2 hours. Corroded by hydrofluoric acid, as the corrosion time prolongs, more porous silicon-oxygen compounds float above the reaction solution. After the reaction is completed, filter, wash with deionized water three times, and dry in a vacuum oven at 120° C. for 2 hours to obtain a porous silicon oxide compound.

[0028] Mix the obtained po...

Embodiment 2

[0031] Put 4.4g of silicon monoxide particles into the corundum ark, put the corundum ark into the tube furnace, and pass nitrogen gas at a flow rate of 100 sccm (standard-state cubic centimeter per minute, standard-state cubic centimeter per minute) for 2 hours. Raise the temperature at 10°C per minute to 900°C, keep the temperature for 20 hours, and cool down to room temperature with the furnace. During this process, part of the silicon monoxide disproportionates to form silicon nanoparticles.

[0032] Place the prepared product in a plastic beaker, add 15ml of hydrofluoric acid aqueous solution with a mass fraction of 20%, stir for 10 minutes, and ultrasonically corrode for 15 minutes. Corroded by hydrofluoric acid, as the corrosion time prolongs, more porous silicon-oxygen compounds float above the reaction solution. After the reaction, filter, wash with deionized water three times, and dry in a vacuum oven at 80° C. for 20 hours to obtain a porous silicon oxide compound. ...

Embodiment 3

[0035] Put 4.4g of silicon monoxide particles into a corundum ark, put the corundum ark into a tube furnace, and feed a mixture of argon and hydrogen at a flow rate of 100 sccm, with a hydrogen ratio of 10%. After 2 hours, the temperature was raised to 1200°C at 10°C per minute, kept for 12 hours, and cooled to room temperature with the furnace. During this process, part of the silicon monoxide was disproportionated to form silicon nanoparticles.

[0036] Place the prepared product in a plastic beaker, add 10ml of hydrofluoric acid aqueous solution with a mass fraction of 40%, stir for 10 minutes, and ultrasonically corrode for 1 hour. Corroded by hydrofluoric acid, as the corrosion time prolongs, more porous silicon-oxygen compounds float above the reaction solution. After the reaction, filter, wash with deionized water three times, and dry in a vacuum oven at 80° C. for 8 hours to obtain a porous silicon oxide compound.

[0037] The production method of the button battery i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com