A kind of electrolyte solution for lithium metal secondary battery and lithium metal secondary battery

A secondary battery and lithium metal technology, which is applied in the field of electrolyte for lithium metal secondary batteries and lithium metal secondary batteries, can solve the problems of low voltage window, low Coulombic efficiency, falsely high battery performance, etc., and achieve the purpose of suppressing lithium branch The production of crystals, the breakthrough of technical barriers, and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

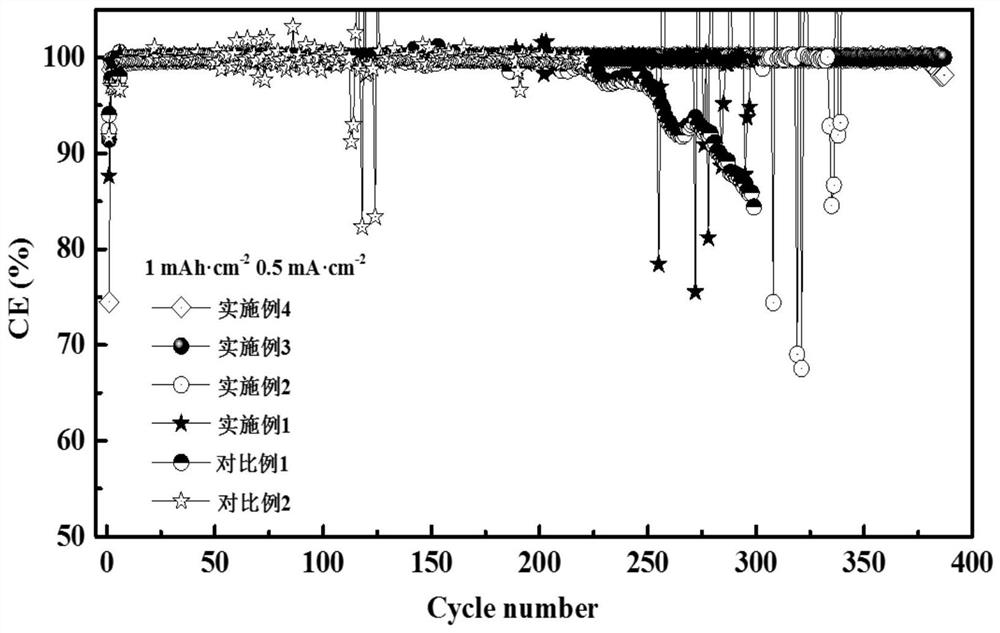

Embodiment 1

[0055] Half-cell assembly: Lithium sheet as negative electrode, 3DCP as positive electrode, 1M LiPF 6 / EC:EMC:DMC=1:1:1 (volume ratio) containing 0.5wt% polyacrylate 2,2,2-trifluoroethyl-dimethacrylate (PTE) and 5wt% fluoroethylene carbonate The ester (FEC) is used as the electrolyte, assembled into a 2025 button lithium battery, and the separator is Celgard2400.

Embodiment 2

[0057] Half-cell assembly: Lithium sheet as negative electrode, 3DCP as positive electrode, 1M LiPF 6 / EC:EMC:DMC=1:1:1 (volume ratio) containing 1wt% polyacrylate 2,2,2-trifluoroethyl-dimethacrylate (PTE) and 5wt% fluoroethylene carbonate (FEC) is the electrolyte, assembled into a 2025 button lithium battery, and the diaphragm is Celgard2400.

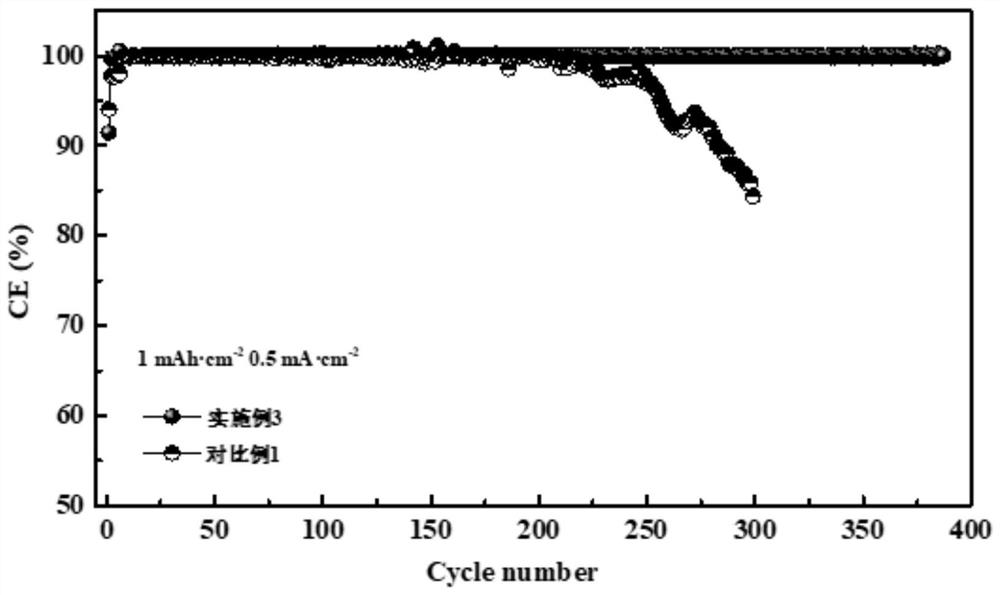

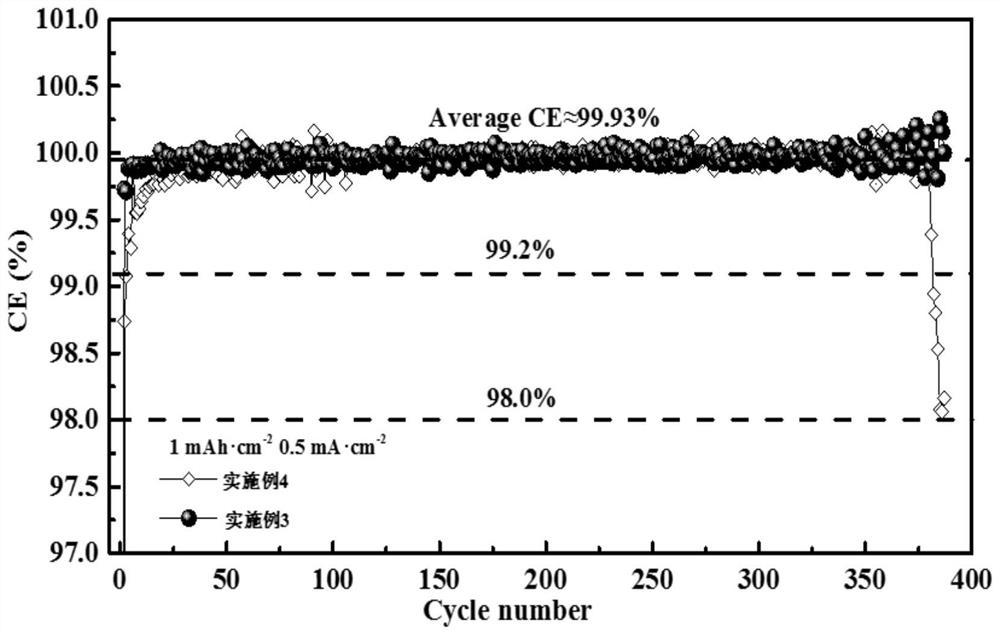

Embodiment 3

[0059] Half-cell assembly: Lithium sheet as negative electrode, 3DCP as positive electrode, 1M LiPF 6 / EC:EMC:DMC=1:1:1 (volume ratio) containing 2wt% polyacrylate 2,2,2-trifluoroethyl-dimethacrylate (PTE) and 5wt% fluoroethylene carbonate (FEC) is the electrolyte, assembled into a 2025 button lithium battery, and the diaphragm is Celgard2400.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com