Acrylic pressure-sensitive adhesive, photo-thermal dual curable adhesive film and preparation method thereof

A technology of acrylic pressure-sensitive adhesive and polyacrylate, which is applied in the direction of pressure-sensitive film/sheet, adhesive, film/sheet-shaped adhesive, etc. No problems such as high, to achieve the effect of low toxicity cost, increase yield, and improve adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

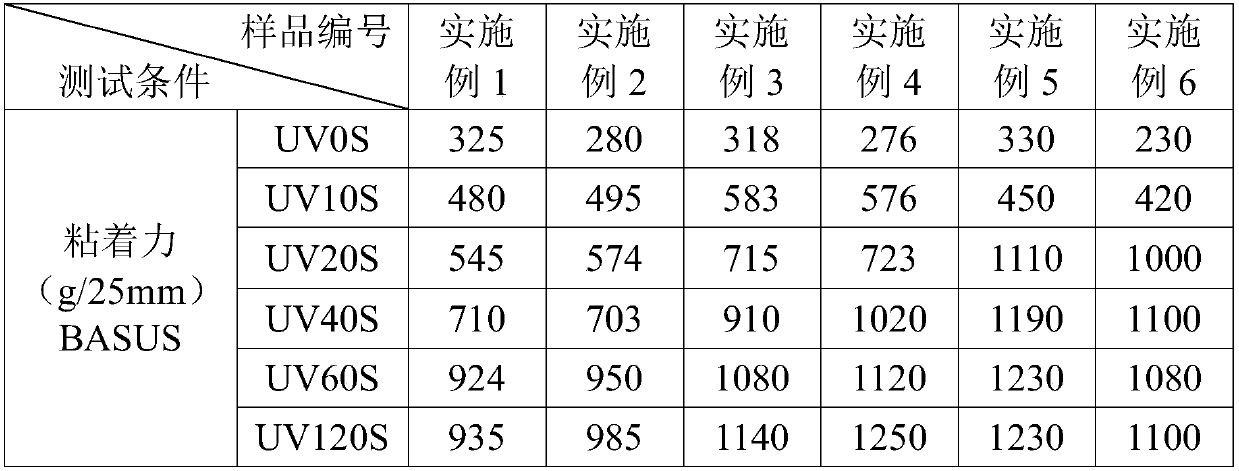

Examples

Embodiment 1

[0044] Prepare raw materials according to the following weight ratio:

[0045] Mixed monomer: 25 parts of butyl acrylate

[0046] 30 parts of methyl methacrylate

[0047] 45 parts of glycidyl methacrylate;

[0048]Initiator: 1 part of dibenzoyl oxide and azobisisobutyronitrile, and dibenzoyl oxide: azobisisobutyronitrile=3:1;

[0049] Organic solvent: 40 parts of a mixture of ethyl acetate and toluene, and ethyl acetate:toluene=1:1

[0050] S01, preparation of polyacrylate prepolymer

[0051] S01-1. According to the weight ratio of the above raw materials, mix butyl acrylate, methyl methacrylate, and glycidyl methacrylate to form a mixed monomer, take 1 / 2 of the mixed monomer, and account for the initiator 1 / 4 of the total amount of dibenzoyl peroxide is dissolved in it, fully dissolved;

[0052] S01-2. In a four-necked flask equipped with a stirrer, a condenser, a nitrogen tube and a dropping funnel, add 2 / 3 of the organic solvent, and add the solution configured in step...

Embodiment 2

[0067] Prepare raw materials according to the following weight ratio:

[0068] Mixed monomer: 20 parts of butyl acrylate

[0069] 40 parts of methyl methacrylate

[0070] 40 parts of glycidyl methacrylate;

[0071] Initiator: a total of 0.6 parts of dibenzoyl oxide and azobisisobutyronitrile, and dibenzoyl oxide: azobisisobutyronitrile=3:1;

[0072] Organic solvent: 30 parts of a mixture of ethyl acetate and toluene, and ethyl acetate:toluene=2:1

[0073] S01, preparation of polyacrylate prepolymer

[0074] S01-1. According to the weight ratio of the above raw materials, mix butyl acrylate, methyl methacrylate, and glycidyl methacrylate to form a mixed monomer, take 1 / 2 of the mixed monomer, and account for the initiator 1 / 4 of the total amount of dibenzoyl peroxide is dissolved in it, fully dissolved;

[0075] S01-2. In a four-necked flask equipped with a stirrer, a condenser, a nitrogen tube and a dropping funnel, add 2 / 3 of the organic solvent, and add the solution con...

Embodiment 3

[0090] Prepare raw materials according to the following weight ratio:

[0091] Mixed monomer: 30 parts of butyl acrylate

[0092] 20 parts of methyl methacrylate

[0093] 50 parts of glycidyl methacrylate;

[0094] Initiator: a total of 1.2 parts of dibenzoyl oxide and azobisisobutyronitrile, and dibenzoyl oxide: azobisisobutyronitrile=4:1;

[0095] Organic solvent: 50 parts of a mixture of ethyl acetate and toluene, and ethyl acetate:toluene=1:2

[0096] S01, preparation of polyacrylate prepolymer

[0097] S01-1. According to the weight ratio of the above raw materials, mix butyl acrylate, methyl methacrylate, and glycidyl methacrylate to form a mixed monomer, take 1 / 2 of the mixed monomer, and account for the initiator 1 / 4 of the total amount of dibenzoyl peroxide is dissolved in it, fully dissolved;

[0098] S01-2. In a four-necked flask equipped with a stirrer, a condenser, a nitrogen tube and a dropping funnel, add 2 / 3 of the organic solvent, and add the solution con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com