A kind of microbead composite solid buoyancy material and preparation method thereof

A solid buoyancy and microbead technology, applied in the field of composite materials, can solve the problems of increasing the overall hollow microbead addition, reducing the density, low density and water absorption of buoyancy materials, achieving good corrosion resistance and processability, and improving The effect of material density and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

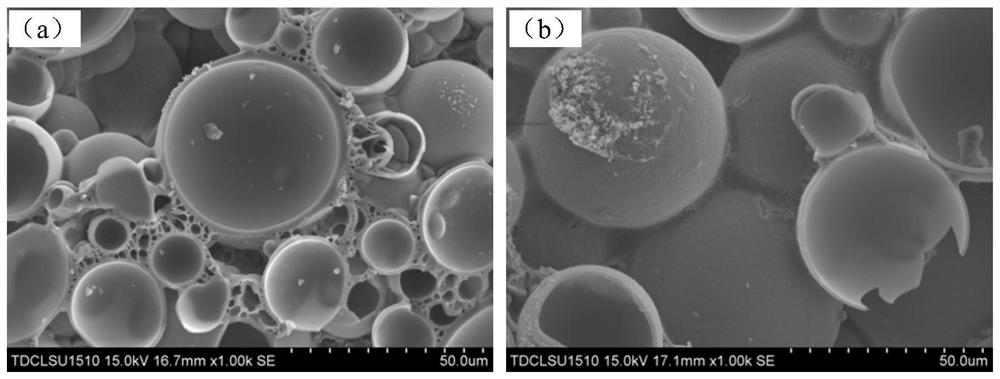

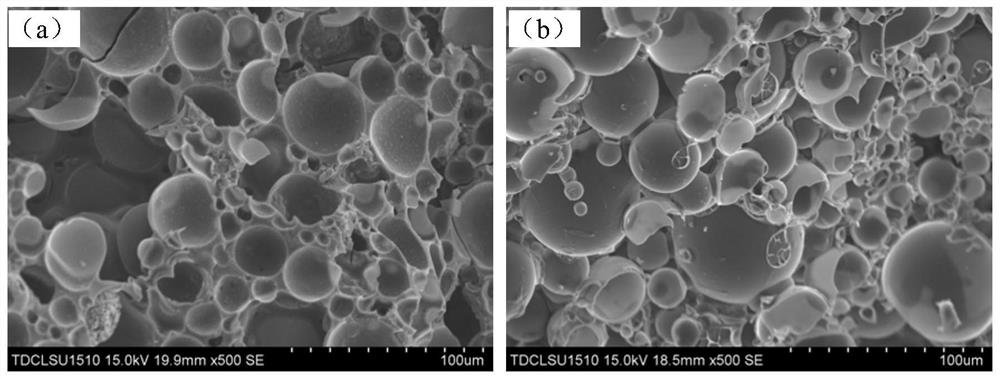

Image

Examples

Embodiment 1

[0041] First, add 20 parts of diluent and 2 parts of silane coupling agent into the blender, stir evenly, pour into the vacuum kneader, and set aside; secondly, add 60 parts of hollow glass microspheres into the vacuum kneader in batches, at 80°C Kneading at a constant speed for 30min under normal pressure conditions to obtain material A 1 ; Then pour 100 parts of epoxy resin into the vacuum mixer, and after stirring at a constant speed at 50 °C for 20 minutes, pour 15 parts of composite curing agent and 2 parts of curing accelerator into the vacuum mixer in turn, Stir at a constant speed for 10 minutes under the state (-0.09MPa) to obtain material B 1 ; then material B 1 Pour into the vacuum kneader, and the material A 1 Knead at a constant speed for 30min under a vacuum state (-0.09MPa) at 80°C to obtain material C 1 ;Finally open the vacuum kneader to take out material C 1 , put it into a mold preheated to 80°C for compaction, then place it on a flat vulcanizer, cure it...

Embodiment 2

[0043] First, add 20 parts of diluent and 2 parts of silane coupling agent into the mixer, stir evenly, pour into a vacuum kneader, and set aside; secondly, mix 60 parts of hollow glass microspheres and 0.8 parts of foamed microspheres, and divide Add batches into a vacuum kneader, and knead at a constant speed for 30 minutes under normal pressure at 80°C to obtain material A 2 ; Then pour 100 parts of epoxy resin into the vacuum mixer, and after stirring at a constant speed at 50 °C for 20 minutes, pour 15 parts of composite curing agent and 2 parts of curing accelerator into the vacuum mixer in turn, Stir at a constant speed for 10 minutes under the state (-0.09MPa) to obtain material B 2 ; then material B 2 Pour into the vacuum kneader, and the material A 2 Knead at a constant speed for 30min under a vacuum state (-0.09MPa) at 80°C to obtain material C 2 ;Finally open the vacuum kneader to take out material C 2 , put it into a mold preheated to 80°C for compaction, then...

Embodiment 3

[0045] First, add 10 parts of diluent and 1.3 parts of silane coupling agent into the mixer, stir evenly, pour into the vacuum kneader, and set aside; secondly, mix 40 parts of hollow glass microspheres and 2 parts of foamed microspheres, and divide Add batches into a vacuum kneader, and knead at a constant speed for 30 minutes under normal pressure at 80°C to obtain material A 3 ; Then pour 100 parts of epoxy resin into the vacuum mixer, and after stirring at a constant speed at 50 °C for 20 minutes, pour 15 parts of composite curing agent and 2 parts of curing accelerator into the vacuum mixer in turn, Stir at a constant speed for 10 minutes under the state (-0.09MPa) to obtain material B 3 ; then material B 3 Pour into the vacuum kneader, and the material A 3 Knead at a constant speed for 30min under a vacuum state (-0.09MPa) at 80°C to obtain material C 3 ;Finally open the vacuum kneader to take out material C 3 , put it into a mold preheated to 80°C for compaction, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com