Regeneration method for deactivated transition metal catalyst

A deactivated catalyst, transition metal technology, applied in catalyst regeneration/reactivation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve permanent catalyst deactivation, metal particle growth Large sintering and other problems, to achieve the effect of removing carbon deposits, eliminating carbon deposits, and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The present embodiment provides a kind of regeneration method of transition metal deactivated catalyst, described method comprises the following steps:

[0061] (1) Ni / Al that will be deactivated 2 o 3 The catalyst is calcined in the air, the gas space velocity is 2000h -1 , the calcination temperature is 1000°C, and the calcination time is 12h;

[0062] (2) The catalyst after the roasting treatment is purged with nitrogen for 0.5h, and the gas space velocity of nitrogen is 500h -1 ;

[0063] (3) Introduce hydrogen as a reducing gas, and the gas space velocity is 800h -1 , a reduction reaction occurs, the reduction temperature is 1000° C., and the reduction time is 1 h to obtain a regenerated catalyst.

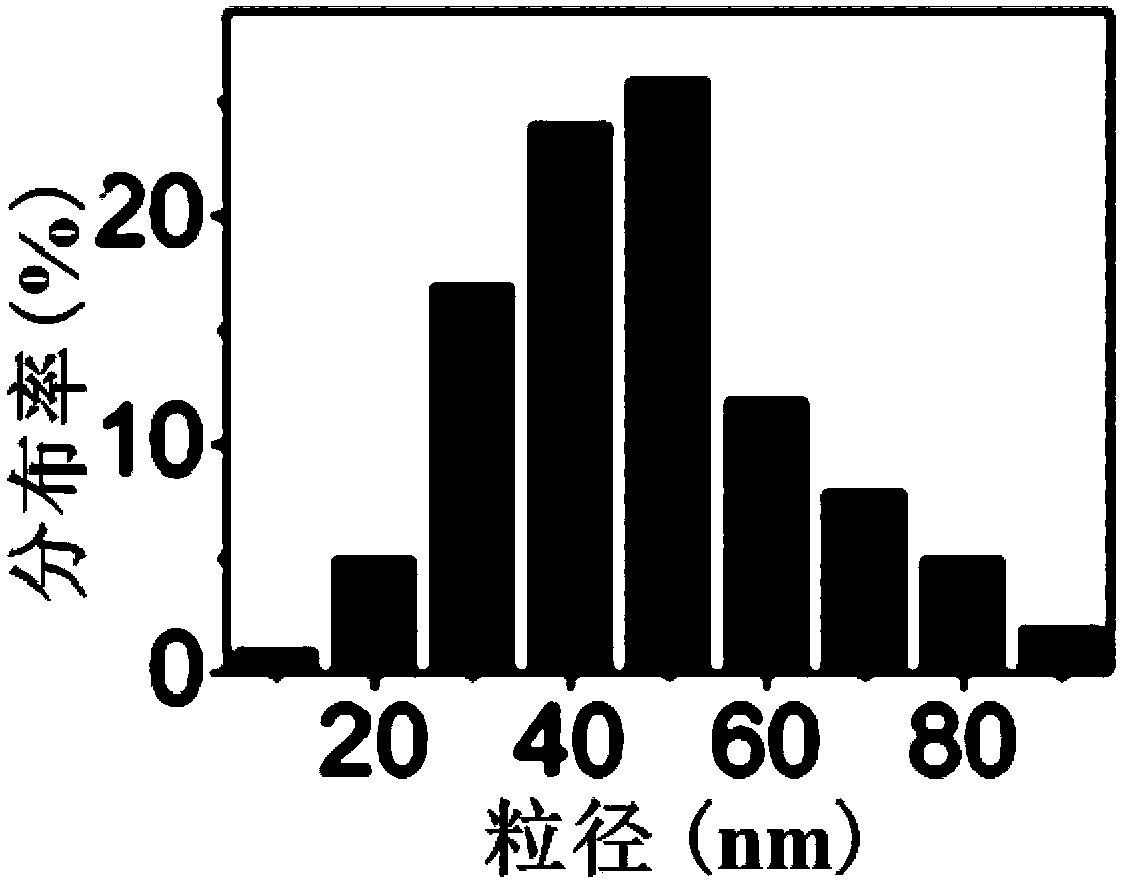

[0064] Fresh Ni / Al that did not participate in the reaction 2 o 3 Catalyst, Ni / Al deactivated after reaction 2 o 3 Catalyst and the regenerated Ni / Al that this embodiment obtains 2 o 3 The catalyst was tested by a transmission electron microscope with an acce...

Embodiment 2

[0068] The invention provides a kind of regeneration method of transition metal deactivated catalyst, described method comprises the following steps:

[0069] (1) Ni / Al that will be deactivated 2 o 3 The catalyst is calcined in the air, the gas space velocity is 2000h -1 , the calcination temperature is 1000°C, and the calcination time is 12h;

[0070] (2) The catalyst after the roasting treatment is purged with nitrogen for 0.5h, and the gas space velocity of nitrogen is 500h -1 ;

[0071] (3) Feed hydrogen and nitrogen mixed gas as reducing gas, wherein the volume percentage of hydrogen is 20%, and the gas space velocity is 1000h -1 , a reduction reaction occurs, the reduction temperature is 900° C., and the reduction time is 2 hours to obtain a regenerated catalyst.

[0072] The regenerated Ni / Al that this embodiment obtains 2 o 3 The catalyst was tested by a transmission electron microscope with an accelerating voltage of 200kV, and its TEM image is shown in Figur...

Embodiment 3

[0075] The present embodiment provides a kind of regeneration method of transition metal deactivated catalyst, described method comprises the following steps:

[0076] (1) Ni / Al that will be deactivated 2 o 3 The catalyst is calcined in a mixed gas of oxygen and nitrogen, wherein the volume percentage of oxygen is 50%, and the gas space velocity is 500h -1 , the calcination temperature is 600°C, and the calcination time is 15h;

[0077] (2) The catalyst after the roasting treatment is purged with nitrogen for 0.1h, and the gas space velocity of nitrogen is 1500h -1 ;

[0078] (3) Introduce hydrogen as a reducing gas, and the gas space velocity is 300h -1 , a reduction reaction occurs, the reduction temperature is 700° C., and the reduction time is 5 hours to obtain a regenerated catalyst.

[0079] The regenerated Ni / Al that this embodiment obtains 2 o 3 The catalyst was used in the methanation reaction under the same reaction conditions as in Example 1, and its catalyti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com