Light-fixable casting compound and method for selective casting substrates/components using said compound

A technology of composition and substrate, applied in the direction of coating, epoxy coating, etc., can solve the problems of inability to achieve high tolerance, different expansion, tension of parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0170] To make the composition according to the present invention, the liquid components are first mixed, and then fillers and other solids are incorporated by means of a laboratory stirrer, laboratory dissolver or speed mixer (Hauschild) until a homogeneous composition is formed.

[0171] The comparative example can be similarly manufactured.

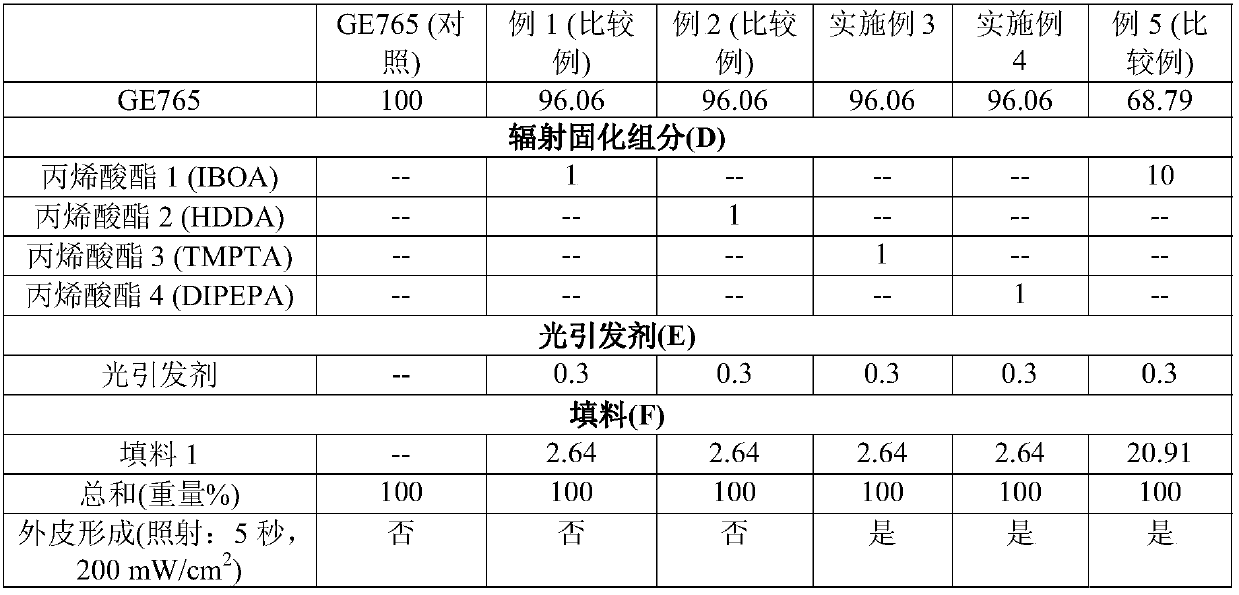

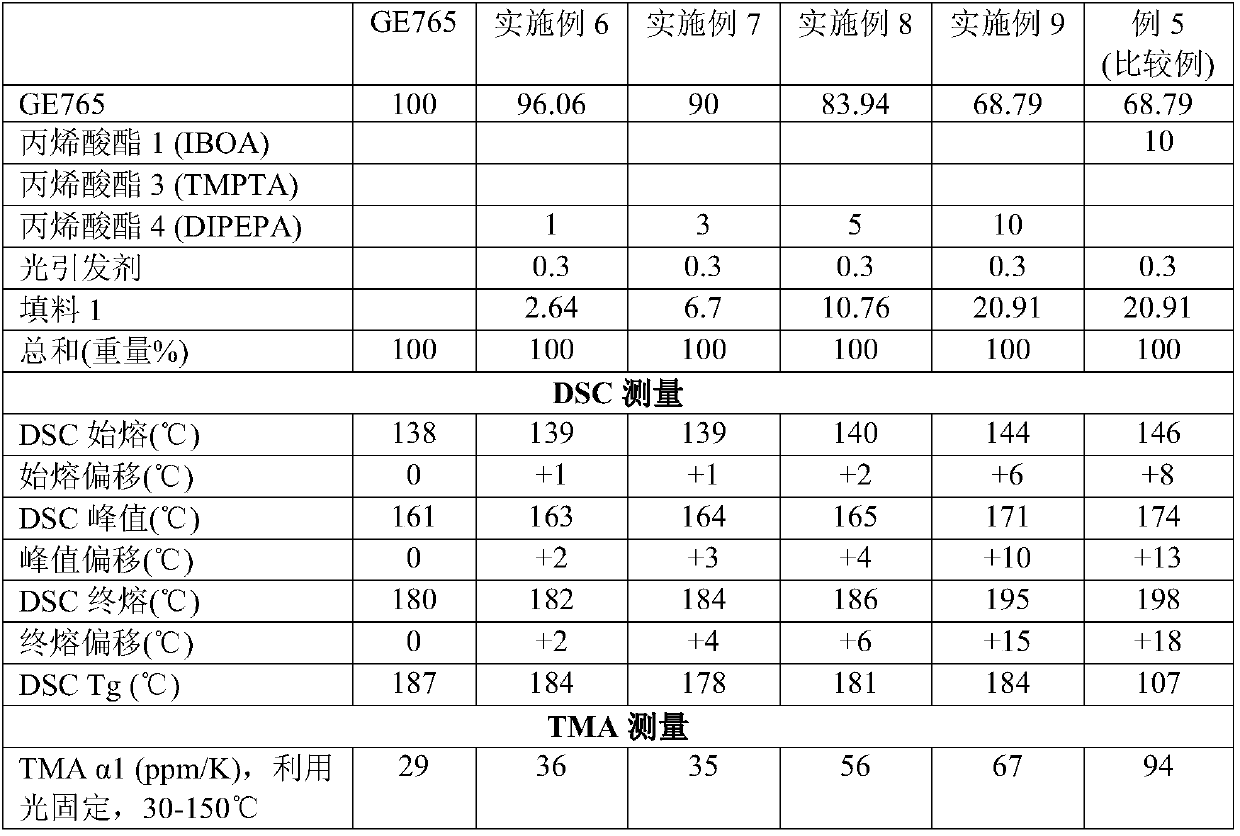

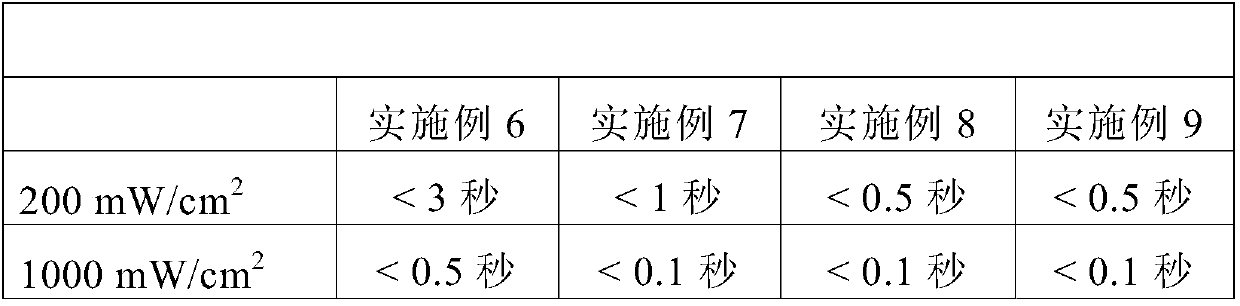

[0172] The compositions of the compositions according to the present invention and comparative examples are listed in the table below. Percents refer to weight percentages, each based on the total weight of the composition.

[0173] In order to make the (meth)acrylate modified composition described in the following example, a commercially available filled anhydride cured one-component epoxy resin composition was used, each of which was added with (meth)acrylate . In order to compensate for the dilution effect of the added radiation curable components, some additional fillers are added so that the filling level remains unchanged compared to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com