Novel double-side linear synchronous motor employing high-temperature superconducting stacked magnet

A high-temperature superconducting, linear synchronization technology, applied in electrical components, electromechanical devices, electric components, etc., to simplify the magnetization process, improve thrust density and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

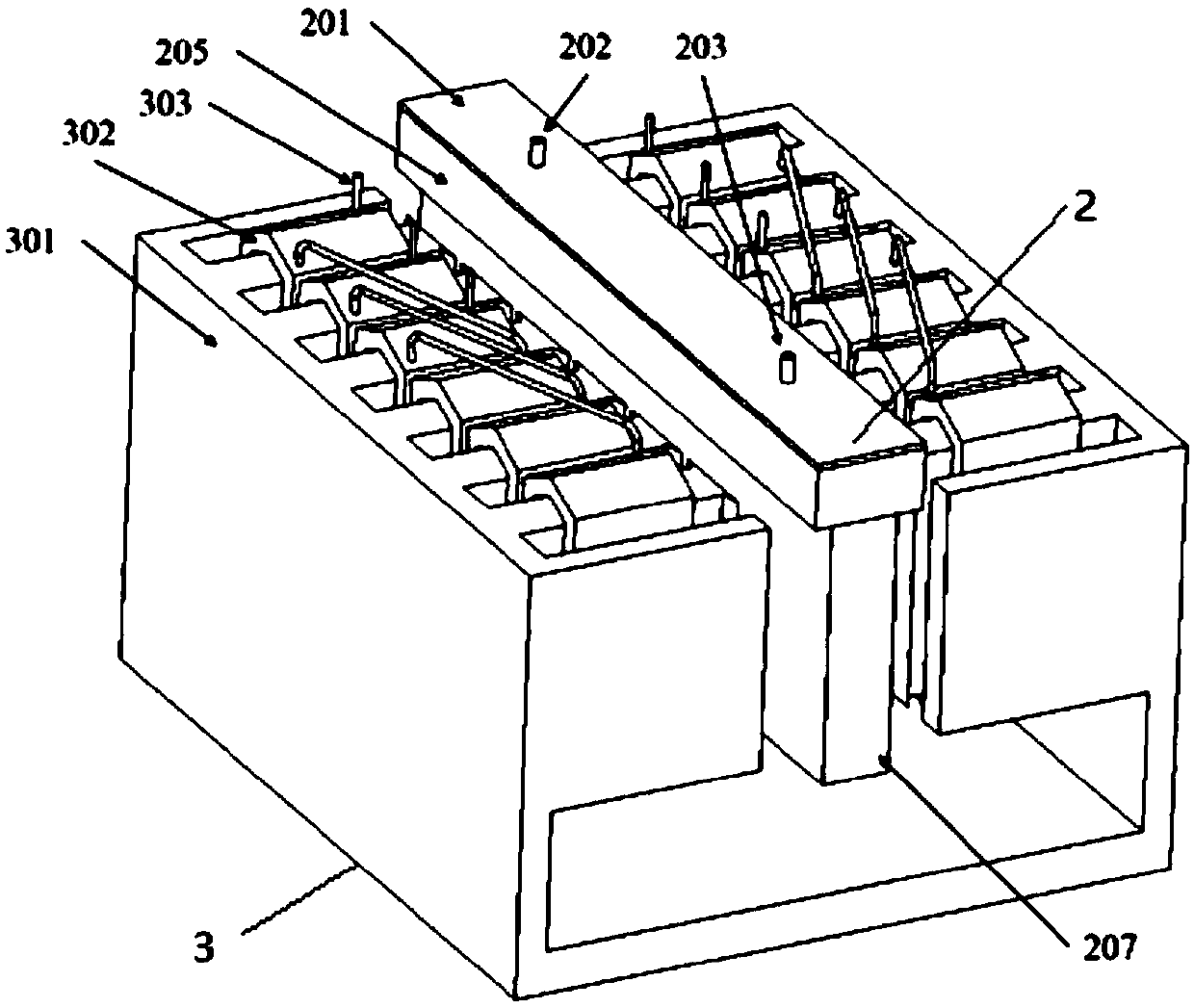

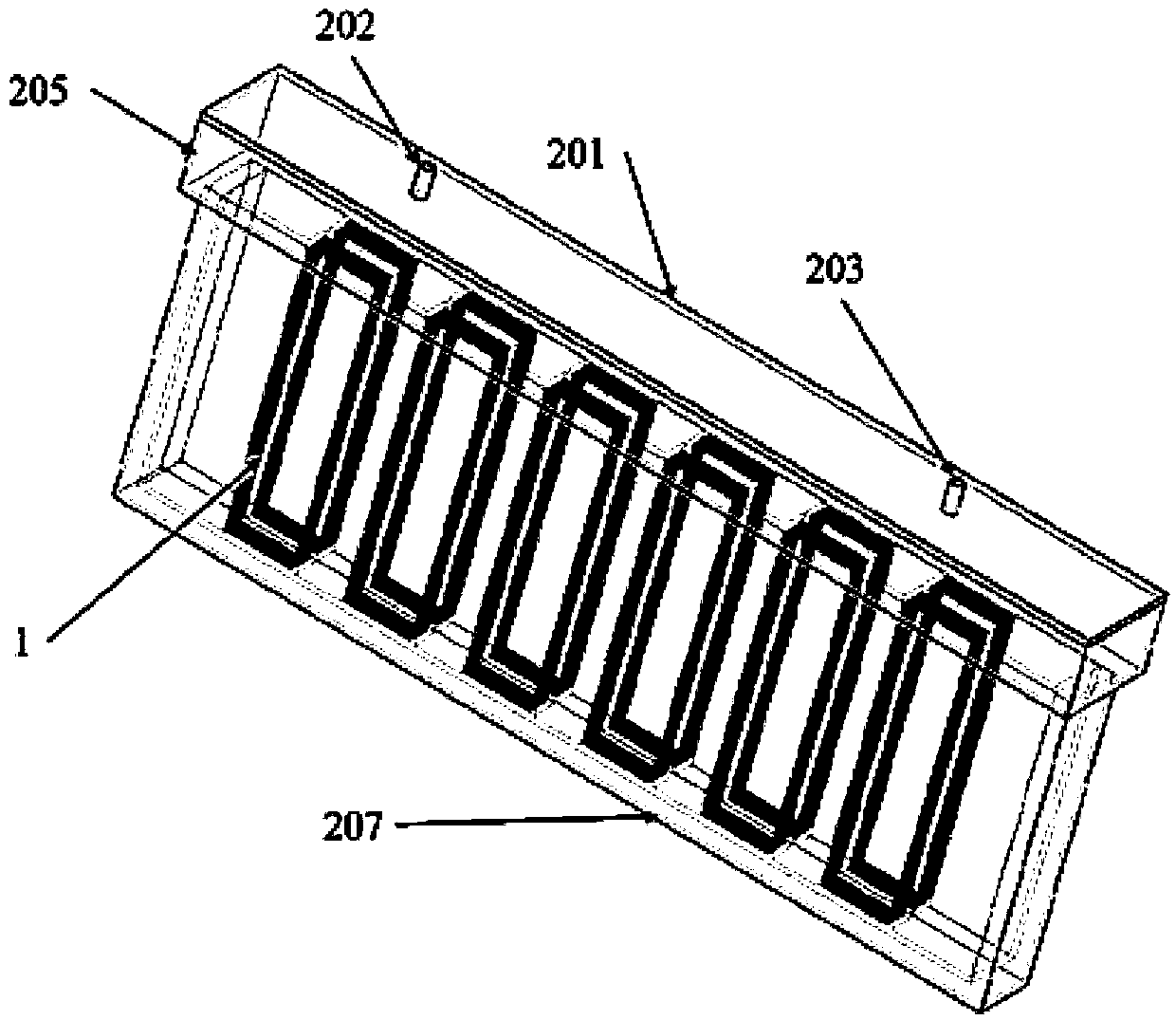

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, a new type of double-sided linear synchronous motor using high-temperature superconducting stacked magnets, including multiple high-temperature superconducting strip stacking structures 1 as the secondary, cooling system 2 and bilaterally opposed primary units 3 .

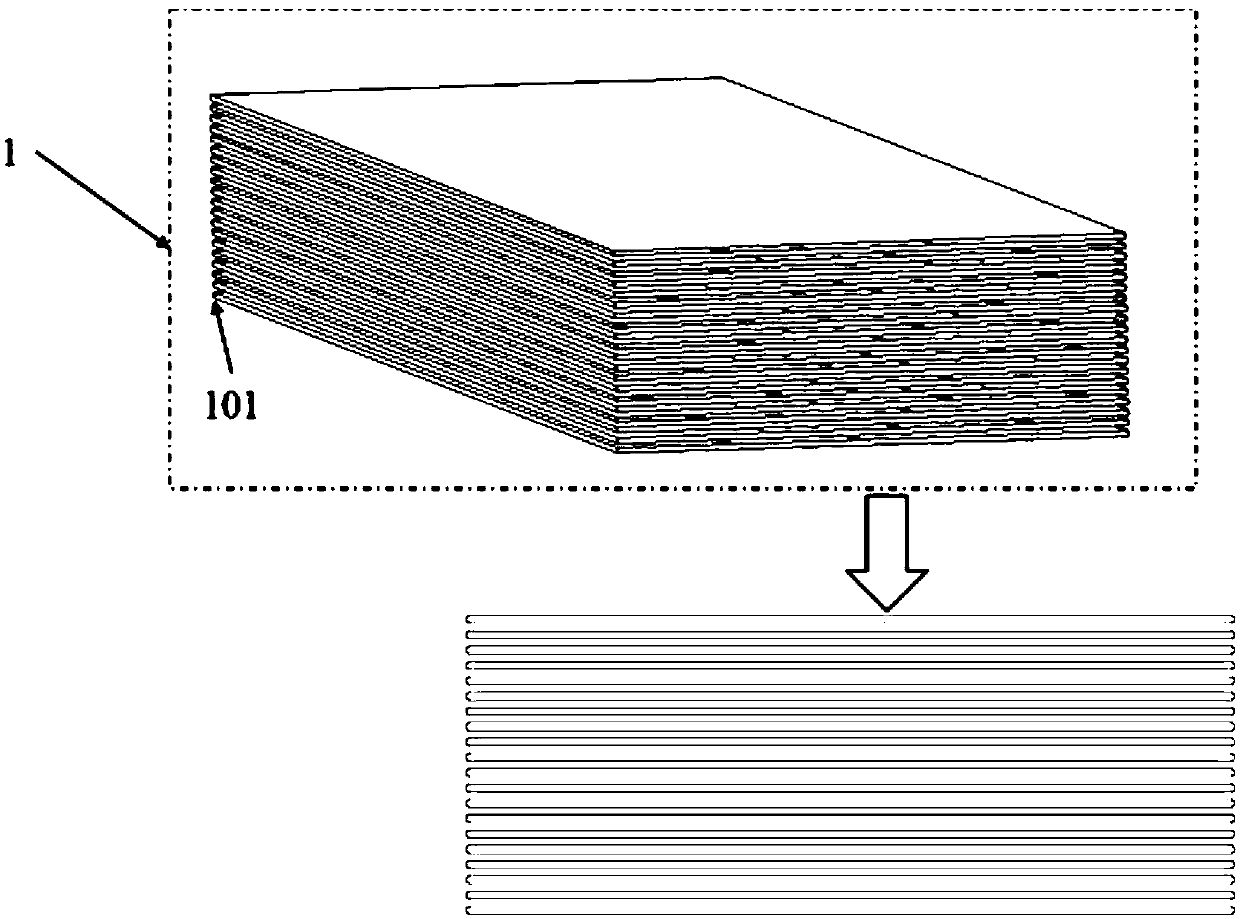

[0024] The high-temperature superconducting tape stack structure 1 is a block formed by encapsulating or heat-melting a plurality of superconducting tape sheets 101 after stacking. Such as figure 2 As shown, the high-temperature superconducting strip stack structure 1 is mainly formed by cutting the high-temperature superconducting strips and stacking them. The selected high-temperature superconducting material is a coated superconducting strip containing YBCO material, which can be selected according to the actual application. The size and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com