Modular automatic production and processing line and production and processing method

A processing line, modular technology, applied in the direction of comprehensive factory control, comprehensive factory control, instruments, etc., can solve the problems of difficult material transportation, long transportation routes, large number of equipment, etc., and achieve high personnel/equipment utilization and stable production capacity. The effect of good performance and simple production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further explained below in conjunction with the accompanying drawings.

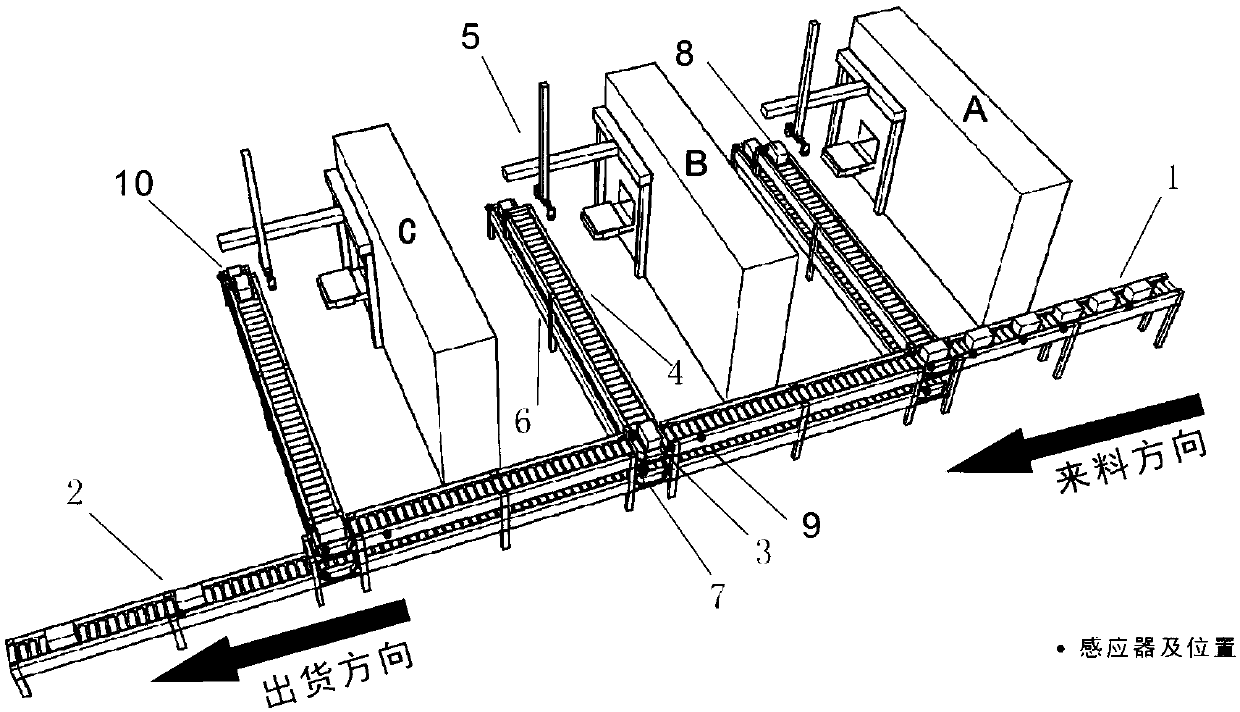

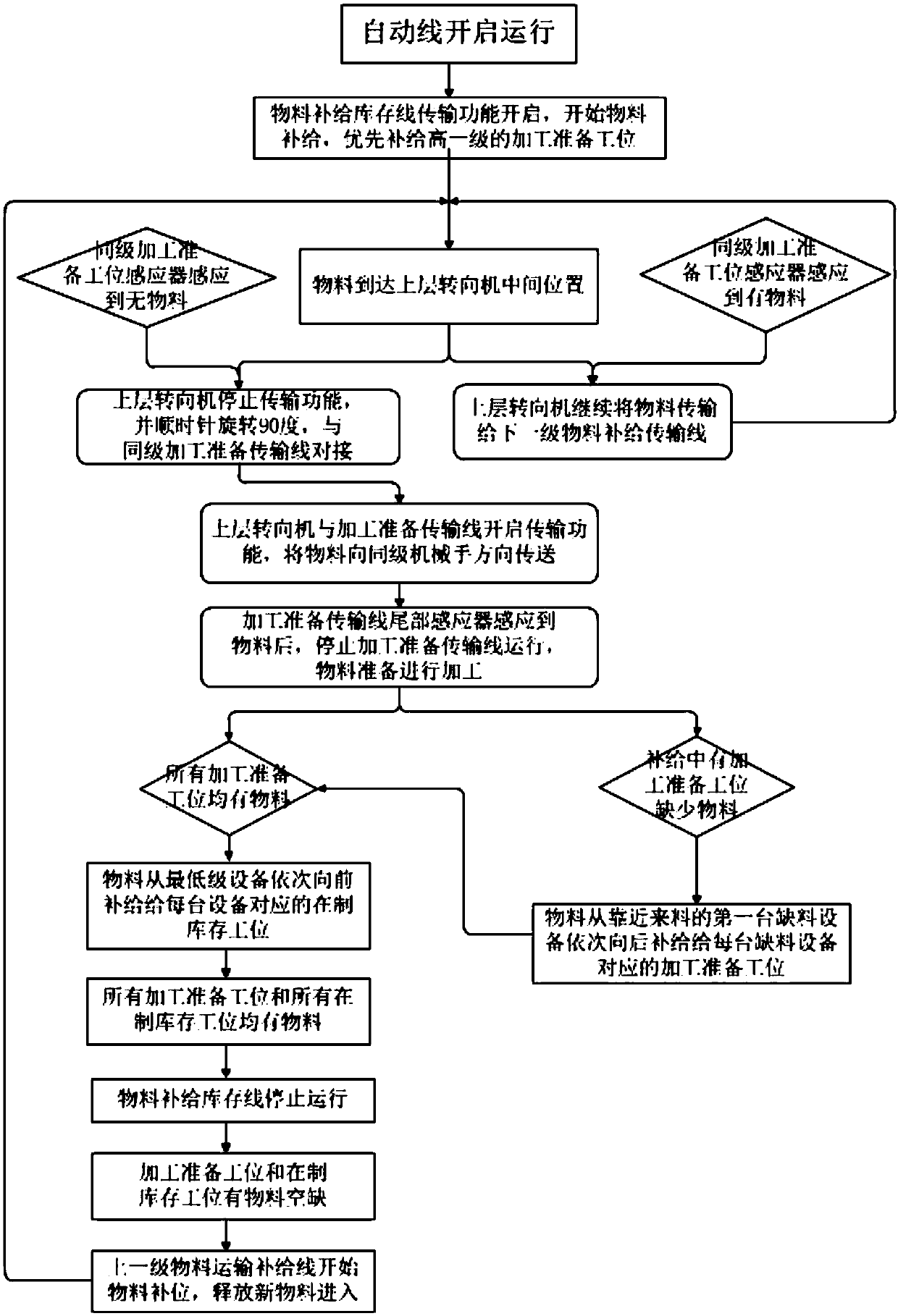

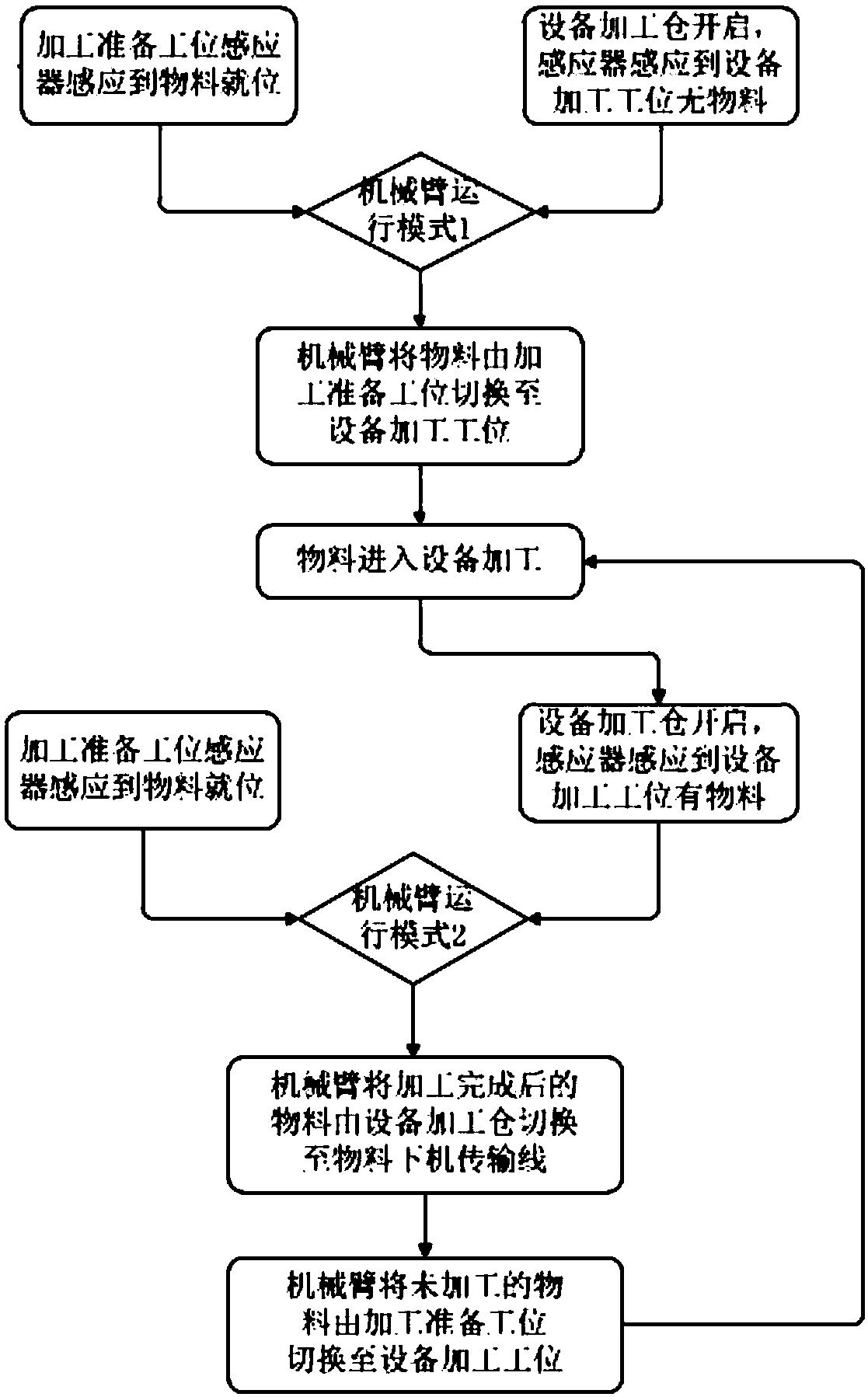

[0051] The invention discloses an automated production and processing line and a control method for line body operation that transform discrete cluster production into modular line production. The line body device includes a material supply transmission line 1, a material delivery transmission line 2, and an upper steering machine 3. Station material preparation transmission line 4, manipulator 5, material off-machine transmission line 6, lower steering machine 7, processing preparation station 8, in-process inventory station 9, and material off-machine transmission preparation station 10. Among them, there are several upper-layer steering machines 3 distributed on the material supply transmission line 1, several station material preparation transmission lines 4, and the station material preparation transmission lines 4 are perpendicular to the material supply transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com