A kind of quantitative detection method of polypropylene beta crystal form nucleating agent

A quantitative detection method and β-crystal technology, applied in the field of analytical chemistry, can solve the problems of unsuitability for rapid and batch detection, high technical requirements for operators, expensive equipment and other problems, to reduce detection costs, low technical requirements, The effect of reducing sample loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

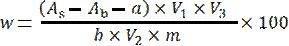

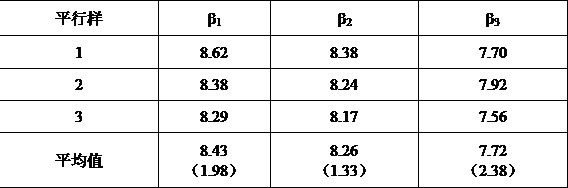

[0025] Weigh 0.5 g (β-nucleating agent 1 or 2 or 3) solid sample, accurate to 0.0001 g, put it in a polytetrafluoroethylene high-pressure digestion tank, add catalyst Cu, carefully add 15 mL of sulfuric acid, and tightly cover the digestion tank , after 30 min of cold digestion, the reaction gas was released. Transfer the digestion tank to a high-temperature oven, set the reaction temperature to 200 °C, and react for 40 min. After the reaction is complete, close the oven, and take out the high-pressure digestion tank after the oven cools down naturally. In a fume hood, deflate slowly until the gas is exhausted. Neutralize the remaining solution with sodium hydroxide solution (400 g / L), filter, and dilute the filtrate to 500 mL with water. Take 1 mL of the above water sample into a 50 mL colorimetric tube, and add water to volume. Add 1.0 mL potassium sodium tartrate solution and 1.5 mL Nessler's reagent respectively, and shake well. Stand for 10 min, and measure the absorb...

Embodiment 2

[0027] Weigh 0.5 g (β-nucleating agent 1) solid sample, accurate to 0.0001 g, put it in a polytetrafluoroethylene high-pressure digestion tank, add the catalyst (copper oxide or copper sulfate powder), and carefully add 15 mL of sulfuric acid , Cover the digestion tank tightly, and after 30 minutes of cold digestion, release the reaction gas. Transfer the digestion tank to a high-temperature oven, set the reaction temperature to 200 °C, and react for 40 min. After the reaction is complete, close the oven, and take out the high-pressure digestion tank after the oven cools down naturally. In a fume hood, deflate slowly until the gas is exhausted. Neutralize the remaining solution with sodium hydroxide solution (400 g / L), filter, and dilute the filtrate to 500 mL with water. Take 1 mL of the above water sample into a 50 mL colorimetric tube, and add water to volume. Add 1.0 mL potassium sodium tartrate solution and 1.5 mL Nessler's reagent respectively, and shake well. Stand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com