High-strength and high-toughness polypropylene composite and preparation method thereof

A composite material and polypropylene technology, which is applied in the field of high-strength and high-toughness polypropylene composite materials and their preparation, can solve problems such as poor toughness and low strength, and achieve the effects of simple preparation process, easy availability of raw materials and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

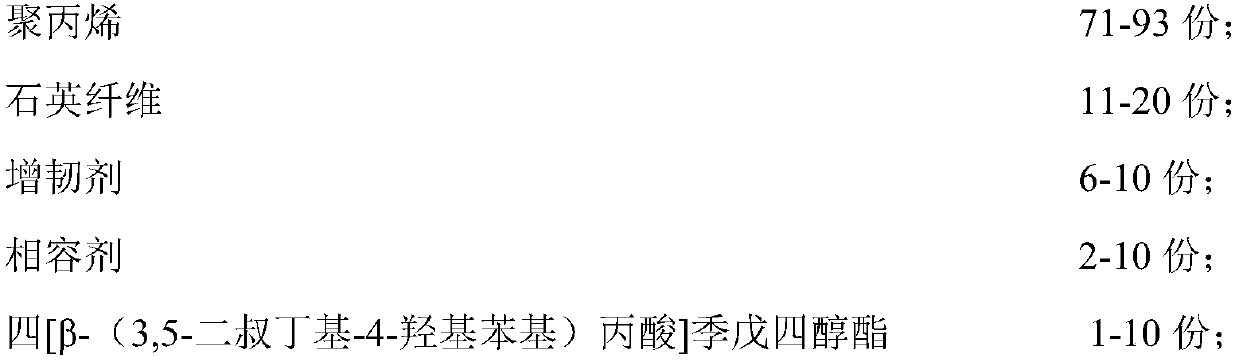

[0024] A high-strength and high-toughness polypropylene composite material, comprising the following raw material components and parts by weight:

[0025]

[0026]

[0027] Among them, the monofilament diameter of the quartz fiber is 9 μm, the length is 3 mm, the softening point is 600 ° C, and the density is 2.52 g / cm 3 .

[0028] The toughening agent is an ethylene octene block copolymer, the molecular weight of the ethylene octene block copolymer is 70000, and the melt index is 2.0 g / min.

[0029] The compatibilizer is maleic anhydride grafted polypropylene, and the density of maleic anhydride grafted polypropylene is 0.87g / cm 3 , the grafting rate is 1.1%, the melt index is 48g / 10min (190°C, 2.16kg), the tensile strength is 26MPa, and the melting point is 138°C.

[0030] A method for preparing a high-strength and high-toughness polypropylene composite material, comprising the following steps:

[0031] (1) Weighing polypropylene, short glass fiber, toughening agent...

Embodiment 2

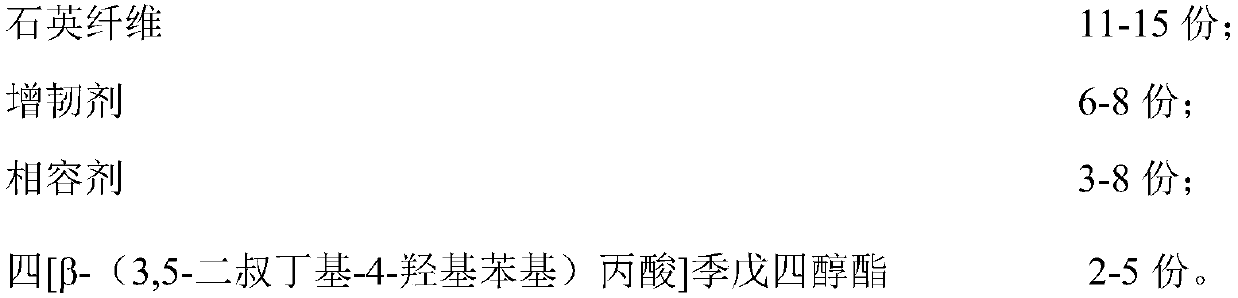

[0071] A high-strength and high-toughness polypropylene composite material, comprising the following raw material components and parts by weight:

[0072]

[0073] Among them, the monofilament diameter of the quartz fiber is 9 μm, the length is 3 mm, the softening point is 600 ° C, and the density is 2.52 g / cm 3 .

[0074] The toughening agent is an ethylene octene block copolymer, the molecular weight of the ethylene octene block copolymer is 70000, and the melt index is 2.0 g / min.

[0075] The compatibilizer is maleic anhydride grafted polypropylene, and the density of maleic anhydride grafted polypropylene is 0.87g / cm 3 , the grafting rate is 1.1%, the melt index is 48g / 10min (190°C, 2.16kg), the tensile strength is 26MPa, and the melting point is 138°C.

[0076] A method for preparing a high-strength and high-toughness polypropylene composite material, comprising the following steps:

[0077] (1) Weighing polypropylene, short glass fiber, toughening agent, compatibil...

Embodiment 3

[0116] A high-strength and high-toughness polypropylene composite material, comprising the following raw material components and parts by weight:

[0117]

[0118] Among them, the monofilament diameter of the quartz fiber is 9 μm, the length is 3 mm, the softening point is 600 ° C, and the density is 2.52 g / cm 3 .

[0119] The toughening agent is an ethylene octene block copolymer, the molecular weight of the ethylene octene block copolymer is 70000, and the melt index is 2.0 g / min.

[0120] The compatibilizer is maleic anhydride grafted polypropylene, and the density of maleic anhydride grafted polypropylene is 0.87g / cm 3 , the grafting rate is 1.1%, the melt index is 48g / 10min (190°C, 2.16kg), the tensile strength is 26MPa, and the melting point is 138°C.

[0121] A method for preparing a high-strength and high-toughness polypropylene composite material, comprising the following steps:

[0122] (1) Weighing polypropylene, short glass fiber, toughening agent, compatibil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com