Resource utilization method suitable for PCB deplating waste liquor

A technology for stripping waste liquid and recycling it, applied in the directions of nitrogen oxides/oxyacids, copper sulfate, nitric acid, etc., which can solve the anti-corrosion requirements of nitrogen oxide overflow equipment in the evaporation process, the high requirements for equipment anti-corrosion, and the cost of electrolysis equipment. Expensive and other issues, to achieve the effect of facilitating sales, increasing product added value, and high utilization of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

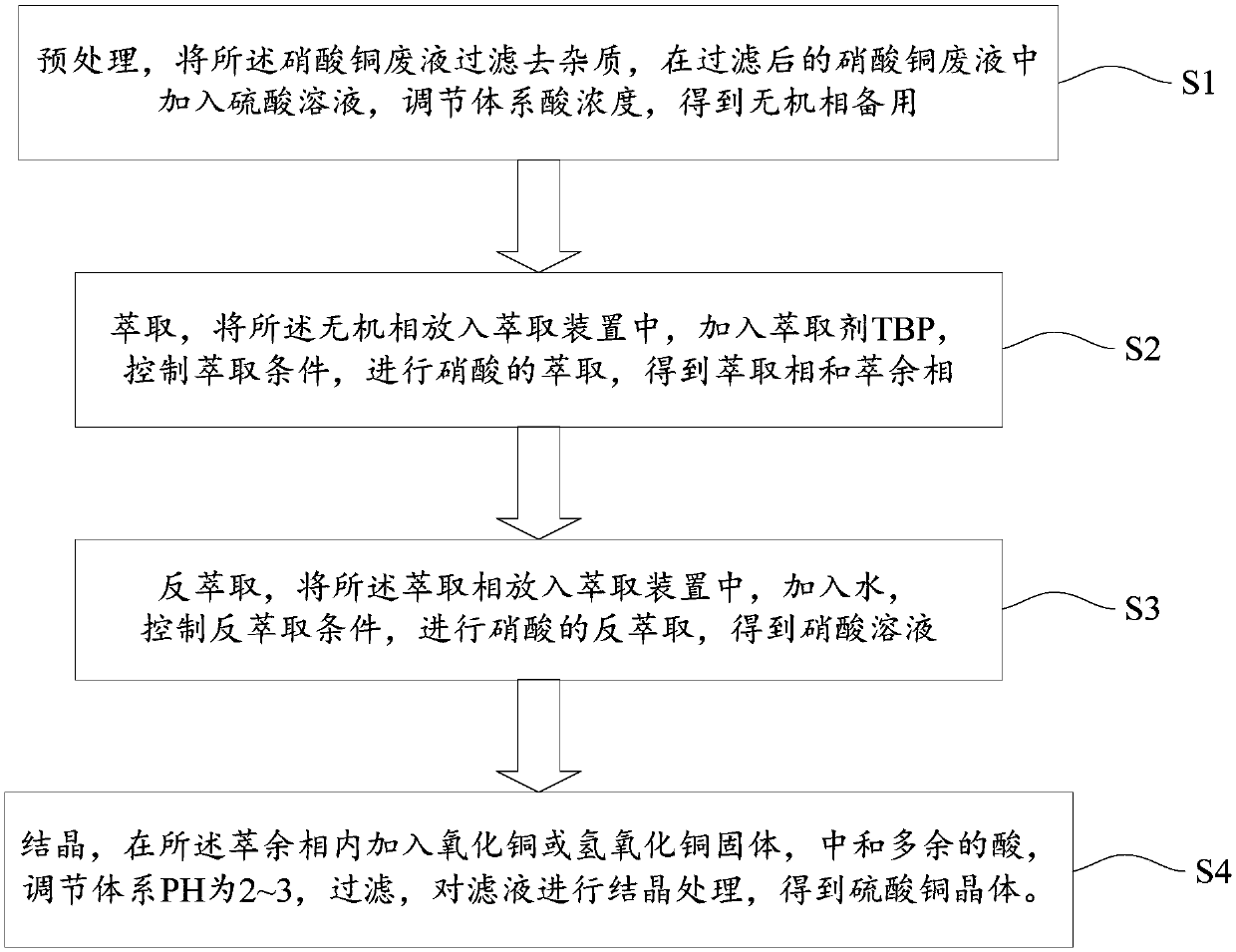

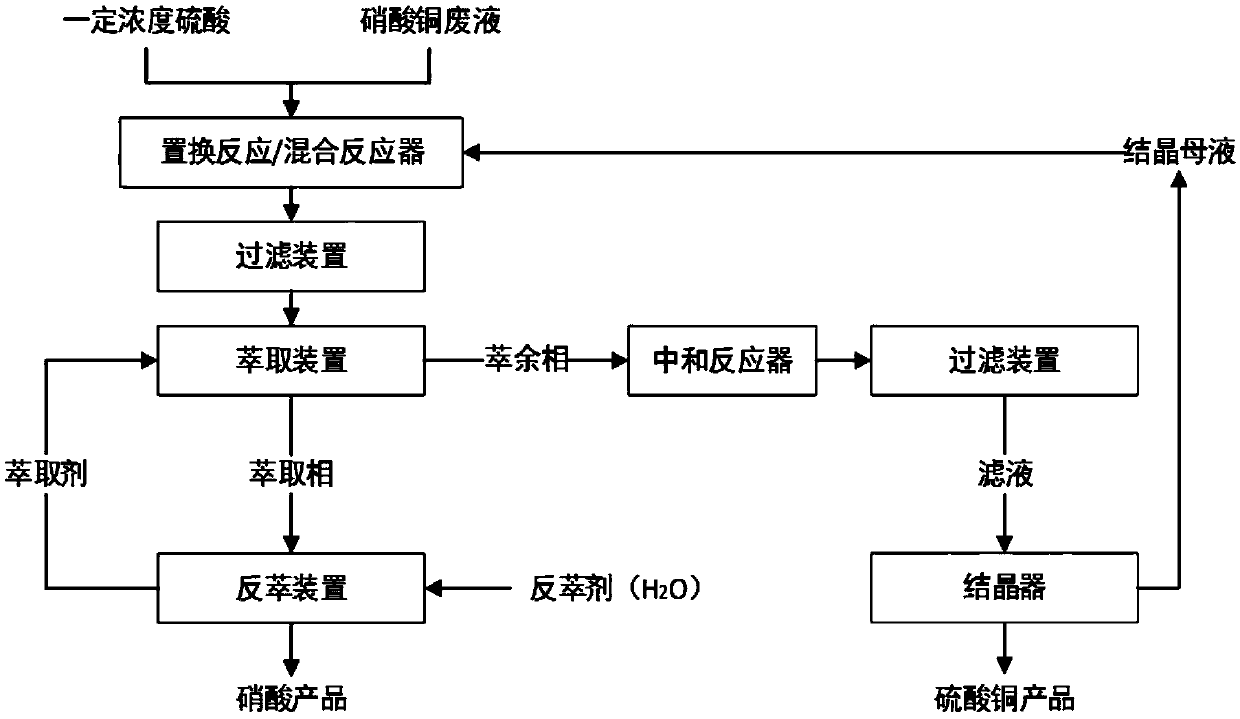

Method used

Image

Examples

Embodiment 1

[0036] 1. Take 1000ml nitric acid waste liquid, analyze copper ion and acid content, slowly add concentrated sulfuric acid equal molar to copper ion, after cooling, analyze acid content to be 5.59mol / L.

[0037] 2. Take 1000ml of the above-prepared solution, and prepare 1000ml of TBP extractant at the same time, pour the two solutions from the upper mouth of the separating funnel, and cover the lid; shake the separating funnel to make the two phases fully contact; after shaking, spin Turn the knob to release the gas in the separatory funnel; continue to oscillate to deflate several times, and the total time of oscillating is 5 minutes.

[0038]3. Put the separatory funnel on the iron ring and wait for the liquid to separate into two clear phases; after the phase separation is complete, the lower liquid is released through the bottom opening, and the upper liquid is released from the upper port.

[0039] 4. The separated upper liquid is extracted multiple times according to the...

Embodiment 2

[0043] 1. Take 1000ml of nitric acid waste liquid, analyze the copper ion and acid content, slowly add concentrated sulfuric acid with twice the molar concentration of copper ion, and analyze the acid content to be 6.6mol / L after cooling.

[0044] 2. Take 1000ml of the above prepared solution. At the same time, prepare 1000ml of TBP extractant, pour the two solutions from the upper mouth of the separatory funnel, and cover the lid; shake the separatory funnel to make the two phases fully contact; after shaking, turn the knob to release the gas in the separatory funnel ;Continue to oscillate and deflate several times, the total time of oscillating is 5min.

[0045] 3. Put the separatory funnel on the iron ring and wait for the liquid to separate into two clear phases; after the phase separation is complete, the lower liquid is released through the bottom opening, and the upper liquid is released from the upper port.

[0046] 4. The separated upper liquid is extracted multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com