Steel/polyurethane sandwich panel and its preparation method and application

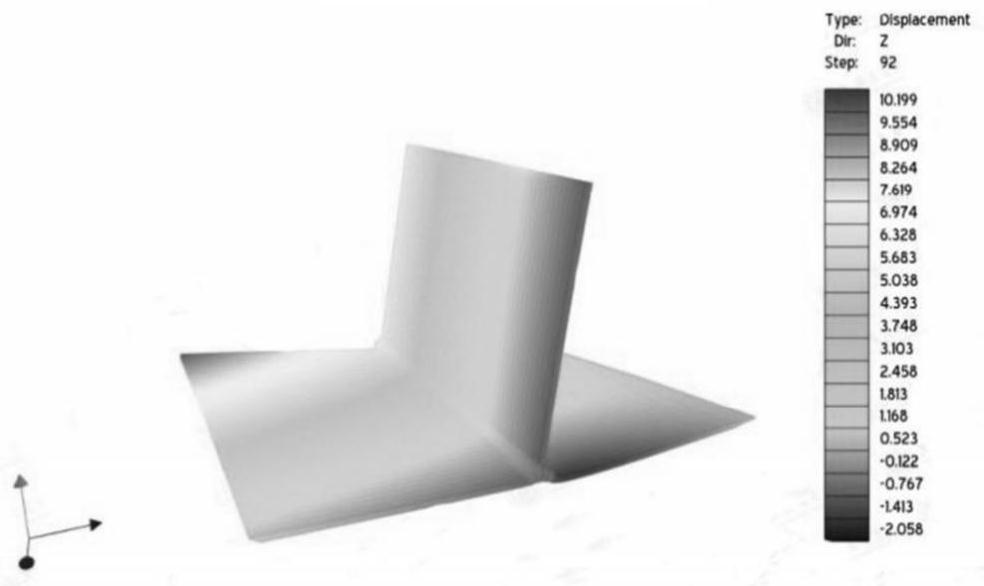

A technology of polyurethane and sandwich panels, applied in chemical instruments and methods, lamination, layered products, etc., can solve the complex preparation process, few engineering fields of steel/polyurethane sandwich panels, and unresolved process problems, etc. problems, achieve high quality, optimize the production line, and avoid irregular deformation of the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The polyurethane core material includes by mass fraction: hard segment material diphenylmethane diisocyanate 30%, soft segment material polypropylene diol with a molecular weight of 400 62.7%, chain extender 1,4-butanediol 2%, catalyst dibutyltin diol Laurate 0.3% and curing agent 3,3'-dichloro-4,4'-diaminodiphenylmethane 5%.

[0032] The method that the present invention prepares steel / polyurethane sandwich plate comprises the steps:

[0033] (1) Polyurethane core material preparation: add diphenylmethane diisocyanate and polypropylene glycol to the reaction kettle, prepolymerize at 60°C and normal pressure for 2 hours to form a polyurethane prepolymer, put it into the pouring machine A barrel, Add 1,4-butanediol, dibutyltin dilaurate and 3,3'-dichloro-4,4'-diaminodiphenylmethane into the barrel of casting machine B, and mix at normal temperature and pressure to obtain a polyurethane core material;

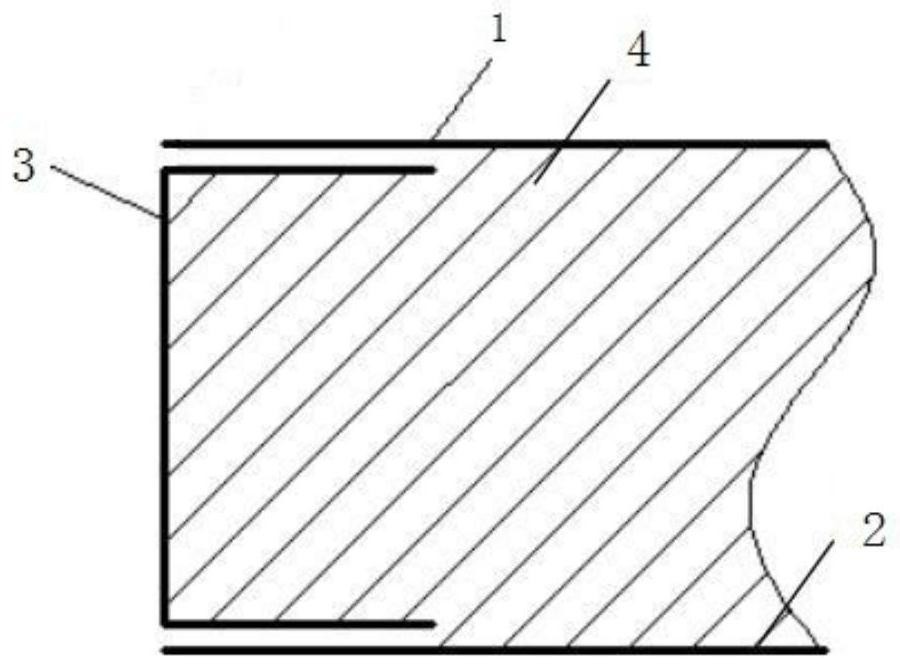

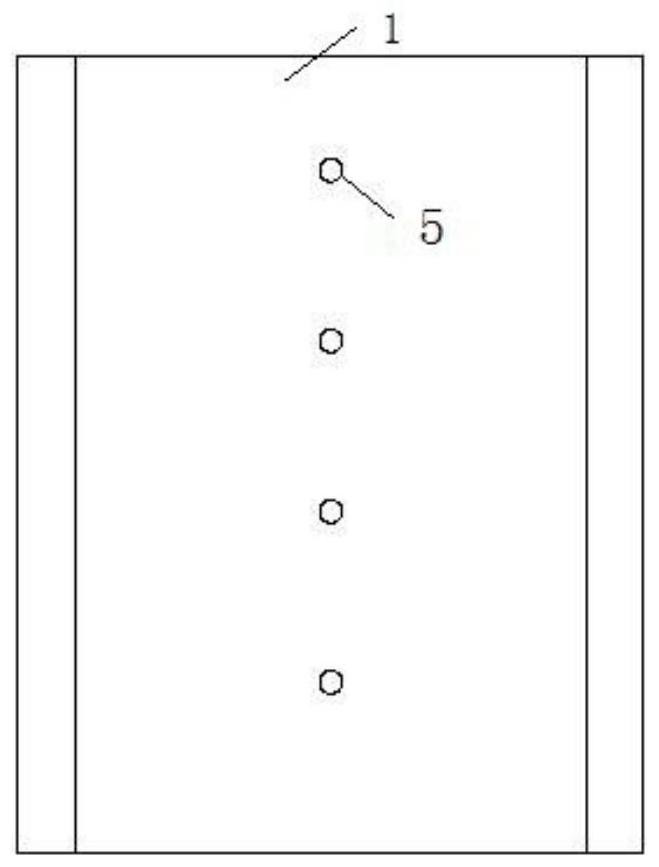

[0034] (2) Cavity preparation: first, the upper and lower steel pan...

Embodiment 2

[0038] The polyurethane core material includes: 20% diphenylmethane diisocyanate as a hard segment material, 77.4% polypropylene glycol with a molecular weight of 400 as a soft segment material, 0.5% chain extender 1,4-butanediol, and dibutyltin diol as a catalyst. Laurate 0.1% and curing agent dimethylthiotoluenediamine 2%.

[0039] The method that the present invention prepares steel / polyurethane sandwich plate comprises the steps:

[0040](1) Polyurethane core material preparation: add diphenylmethane diisocyanate and polypropylene glycol to the reaction kettle, prepolymerize at 60°C and normal pressure for 2 hours to form a polyurethane prepolymer, put it into the pouring machine A barrel, Add 1,4-butanediol, dibutyltin dilaurate and dimethylthiotoluenediamine into the B barrel of the pouring machine, and mix at normal temperature and pressure to obtain a polyurethane core material;

[0041] (2) Cavity preparation: first, the upper and lower steel panels are treated, that...

Embodiment 3

[0045] The polyurethane core material includes by mass fraction: hard segment material diphenylmethane diisocyanate 50%, soft segment material polypropylene diol with a molecular weight of 400 47.4%, chain extender 1,4-butanediol 0.5%, catalyst dibutyltin diol Laurate 0.1% and curing agent dimethylthiotoluenediamine 2%.

[0046] The method that the present invention prepares steel / polyurethane sandwich plate comprises the steps:

[0047] (1) Polyurethane core material preparation: add diphenylmethane diisocyanate and polypropylene glycol to the reaction kettle, prepolymerize at 60°C and normal pressure for 2 hours to form a polyurethane prepolymer, put it into the pouring machine A barrel, Add 1,4-butanediol, dibutyltin dilaurate and dimethylthiotoluenediamine into the B barrel of the pouring machine, and mix at normal temperature and pressure to obtain a polyurethane core material;

[0048] (2) Cavity preparation: firstly, the upper steel panel and the lower steel panel are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com