Rice processing technology

A rice processing and crafting technology, applied in application, grain processing, agriculture, etc., to reduce thermal expansion and contraction, curb the generation of lipid peroxide, and prevent insects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

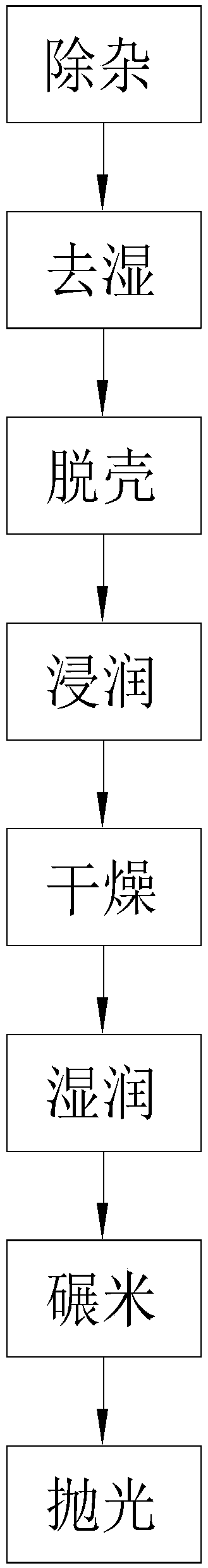

Image

Examples

preparation example Construction

[0036] The preparation method of the tea water adopted in the step 4 is as follows:

[0037] a. The tea leaves are placed in hot water for stirring and cleaning, and a filter sieve is used for solid-liquid separation to obtain clean tea leaves;

[0038] b. Soak the clean tea leaves in boiling water for 5-25 minutes to obtain a mixture of tea leaves and water;

[0039] c. Centrifugally filter the mixture of tea leaves and water, and then perform fine filtration to obtain tea.

[0040] The preparation method of the tea-water mixture used in step 6 is: take the hot tea obtained in step c, add pepper powder in a ratio of 20:1, stir evenly, heat for 5-10 minutes, and filter to obtain the tea-water mixture.

[0041] The stirring speed in step a is 1-10r / min.

[0042] The temperature of the hot air for drying the grains in step 2 is 35-45° C. Take out and stir after every 50-60 minutes of drying, and then dry after cooling for 10 minutes until the moisture content of the grains is ...

Embodiment 1

[0048] The invention discloses a rice processing technology, comprising the following method steps:

[0049] 1. Impurity removal: The threshed rice enters the first-level vibrating screen through the elevator for preliminary cleaning to remove large impurities in the grain, and then the second-level vibrating screen is used for second-time removal of impurities, and the stone remover is used to remove the broken particles. stone, and then go through a magnetic separator to remove metal impurities;

[0050] 2. Dehumidification: use the hot air drying method to spread the impurity-removed grains in the drying room for intermittent drying;

[0051] 3. Shelling: Send the dried grains to the rubber roller huller for shelling to obtain brown rice;

[0052] 4. Soaking: Soak brown rice in tea water for 5 minutes;

[0053] 5. Drying: the soaked brown rice is dried at low temperature through a low-temperature freeze dryer, and the moisture content of the semi-finished product obtained...

Embodiment 2

[0058] The invention discloses a rice processing technology, comprising the following method steps:

[0059] 1. Impurity removal: The threshed rice enters the first-level vibrating screen through the elevator for preliminary cleaning to remove large impurities in the grain, and then the second-level vibrating screen is used for second-time removal of impurities, and the stone remover is used to remove the broken particles. stone, and then go through a magnetic separator to remove metal impurities;

[0060] 2. Dehumidification: use the hot air drying method to spread the impurity-removed grains in the drying room for intermittent drying;

[0061] 3. Shelling: Send the dried grains to the rubber roller huller for shelling to obtain brown rice;

[0062]4. Soaking: Soak brown rice in tea water for 10 minutes;

[0063] 5. Drying: the soaked brown rice is dried at low temperature through a low-temperature freeze dryer, and the moisture content of the semi-finished product obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com