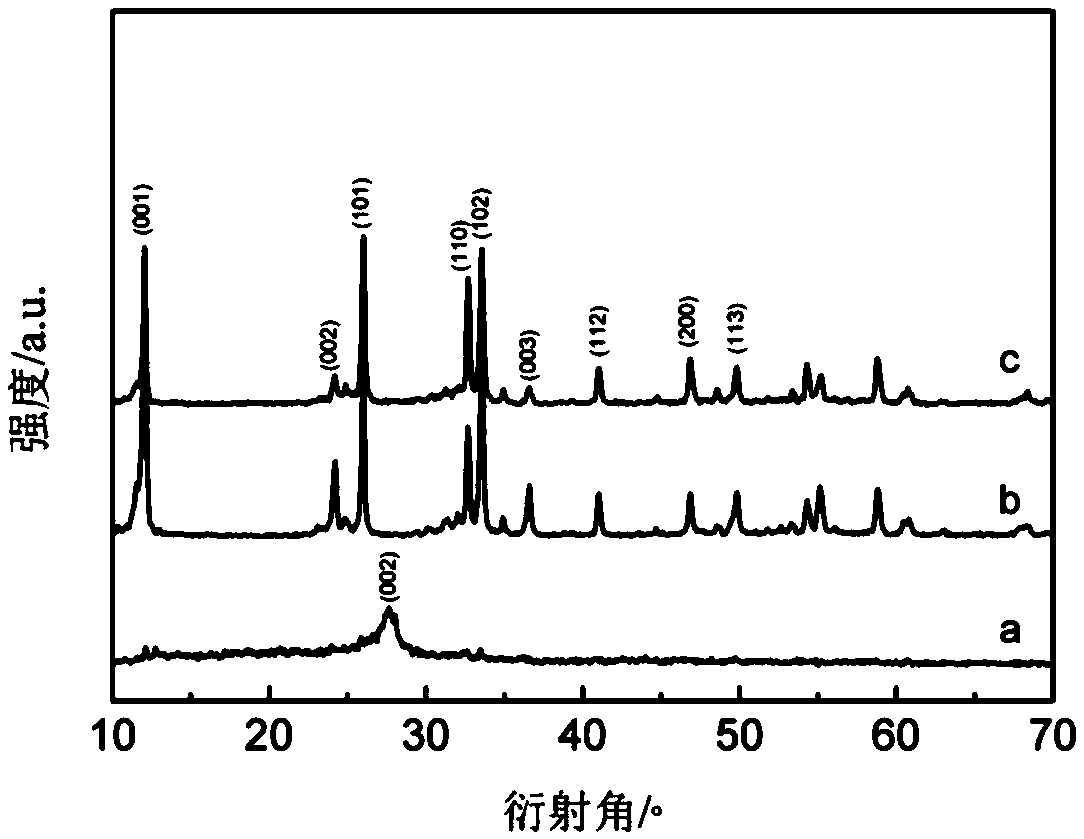

BiOCl/graphite-like phase carbon nitride composite photocatalyst with (010) crystal face exposed and preparation method and application thereof

A graphite phase carbon nitride, composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, special compound water treatment, etc., to achieve high photocatalytic activity and promote separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The exposed (010) crystal plane BiOCl / g-C described in the present invention 3 N 4 The preparation method of composite photocatalyst comprises the following steps:

[0030] Step 1: Bi(NO 3 ) 3 ·5H 2 O, NaCl was dissolved in deionized water, and after stirring at room temperature for 1 h, the pH value was adjusted to 6 with 1 mol / L NaOH solution. After stirring at room temperature for 1 h, the reaction precursor solution was obtained, and the precursor solution was transferred to the hydrothermal reaction kettle. React at 160°C. After the reaction is completed and the temperature drops to room temperature, take out the reactor, let it stand to remove the supernatant, wash the precipitate with deionized water and absolute ethanol three times, and dry it at 70°C. BiOCl powder with exposed (010) crystal face was obtained after grinding; Bi(NO 3 ) 3 ·5H 2 The amount ratio of O and NaCl is 1:1.

[0031] Step 2: Weigh urea into an alumina crucible with a cover and plac...

Embodiment 1

[0040] Step 1: Mix 8mmol Bi(NO 3 ) 3 ·5H 2 Dissolve 0.8mmol NaCl in 48mL deionized water, stir at room temperature for 1h, adjust its pH to 6 with 1mol / L NaOH solution, and continue stirring at room temperature for 1h to obtain a reaction precursor, which is then transferred to a hydrothermal reactor , reacted at 160°C for 2 hours, and after the reaction temperature dropped to room temperature, the reactor was taken out, and the supernatant was removed by standing, and the precipitate was washed three times with deionized water and absolute ethanol respectively. After drying and grinding, BiOCl powder with exposed (010) crystal face is obtained;

[0041] Step 2: Weigh 30g of urea into an alumina crucible with a cover and place it in a muffle furnace, set the heating rate at 15°C / min, keep it at 550°C for 4h, cool to room temperature and grind to obtain a light yellow g-C 3 N 4 Powder;

[0042] Step 3: Weigh 0.3g of BiOCl powder with exposed (010) crystal plane and dissolv...

Embodiment 2

[0044] Step 1: Mix 8mmol Bi(NO 3 ) 3 ·5H 2 Dissolve 0.8mmol NaCl in 48mL deionized water, stir at room temperature for 1h, adjust its pH to 6 with 1mol / L NaOH solution, and continue stirring at room temperature for 1h to obtain a reaction precursor, which is then transferred to a hydrothermal reactor , reacted at 160°C for 4.5h, after the reaction temperature dropped to room temperature, the reactor was taken out, and the supernatant was removed by standing, and the precipitate was washed three times with deionized water and absolute ethanol respectively, and then heated at 70°C Obtain the BiOCl powder body that exposes (010) crystal face after drying and grinding;

[0045] Step 2: Weigh 30g of urea into an alumina crucible with a cover and place it in a muffle furnace, set the heating rate at 15°C / min, keep it at 550°C for 4h, cool to room temperature and grind to obtain a light yellow g-C 3 N 4 Powder;

[0046] Step 3: Weigh 0.3g of BiOCl powder with exposed (010) cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com