A medium and high voltage inverter DC capacitor pre-charging device

A technology of medium and high voltage inverters and DC capacitors, applied in battery circuit devices, circuit devices, irreversible AC power input conversion to DC power output, etc., can solve the problem of increased volume and cost of inverters, large number of current-limiting resistors and diodes and other issues to achieve the effect of reducing volume and weight, reducing quantity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] refer to figure 1 As shown, the present invention discloses a medium-voltage inverter DC capacitor pre-charging device, including:

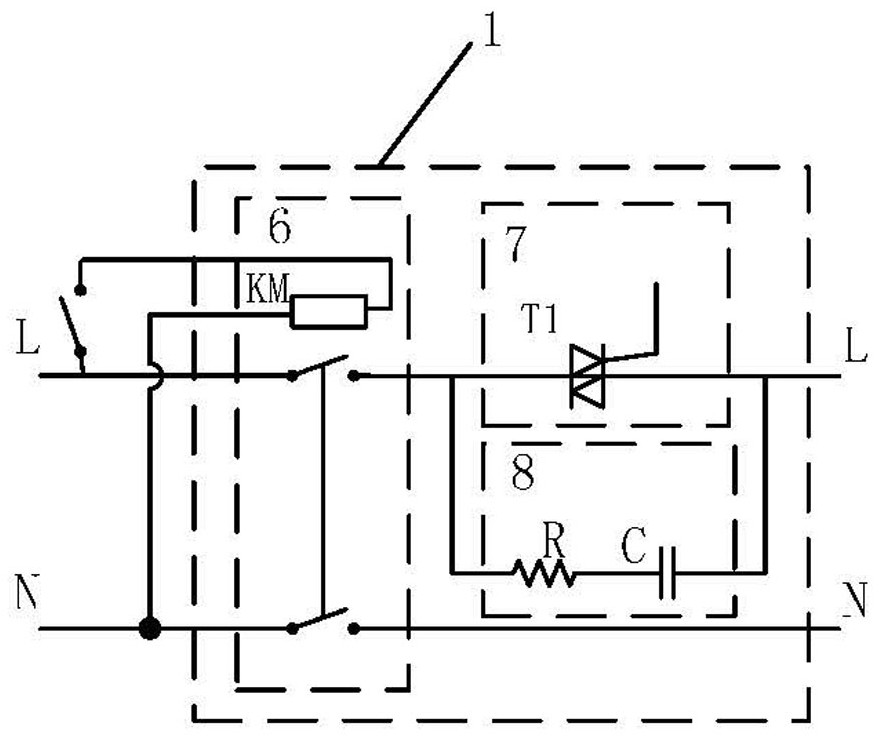

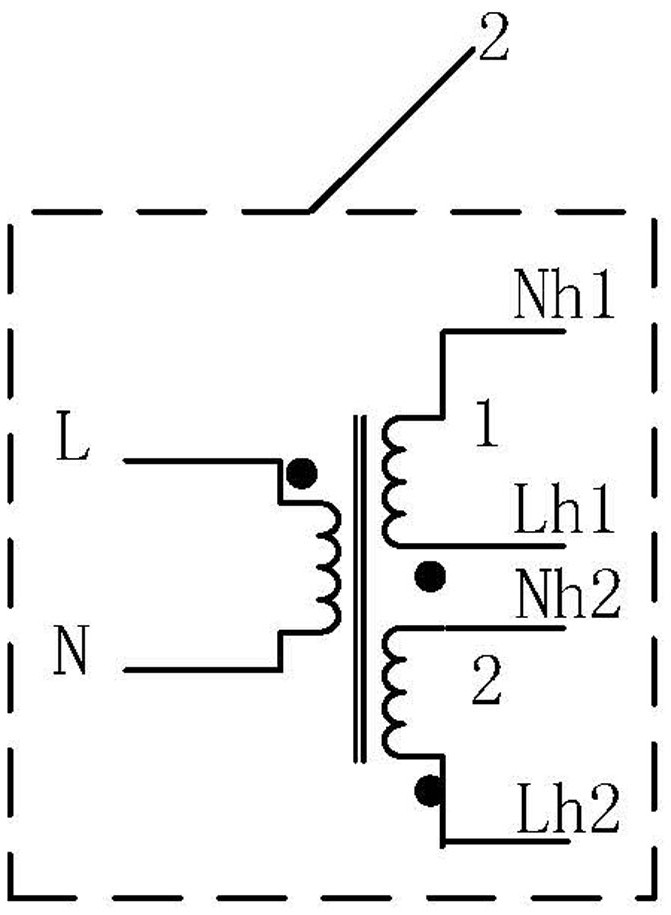

[0027] Low-voltage control circuit 1, the input terminal is connected to the single-phase 220V power supply of the grid, such as figure 2 As shown, it includes a low-voltage contactor KM6, a bidirectional thyristor T1 7, and an RC protection circuit 8 connected in parallel with the thyristor. By remotely controlling the low-voltage contactor KM 6, the single-phase 220V of the power grid is connected; the two-phase thyristor T1 7 is connected in series with the 220V circuit Among them, the RC protection circuit 8 is connected in parallel with the two-phase thyristor T1 7; by controlling the firing angle of the two-phase thyristor T1 7, the output voltage is gradually adjusted to 220V; the output of the low-voltage control circuit 1 is connected to the original of the multi-winding isolation transformer 2 side, input voltage 220V to the mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com