Method for preparing nano zero-valent iron from water purification plant iron-containing sludge and application

A nano-zero-valent iron and water purification plant technology, applied in water/sludge/sewage treatment, water pollutants, nanotechnology, etc., can solve the problems of unfavorable large-scale industrial application, complicated preparation process, and high cost of raw materials. Achieve the effect of convenient recycling modification, simple preparation method and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

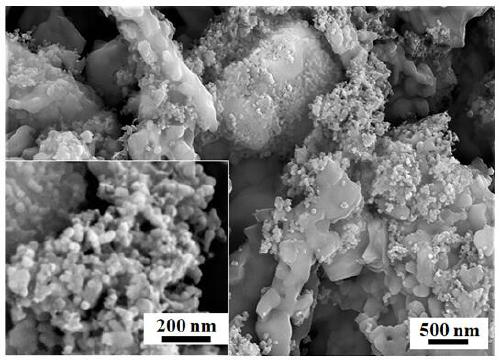

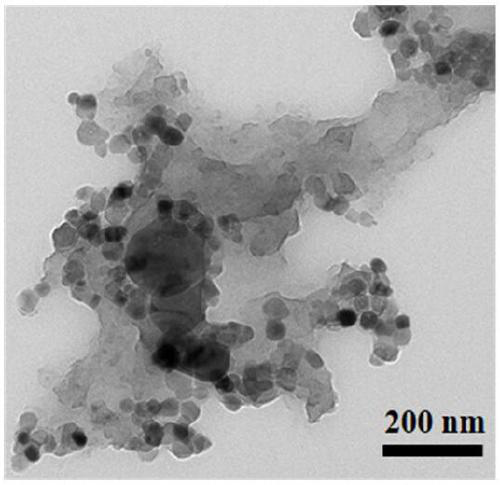

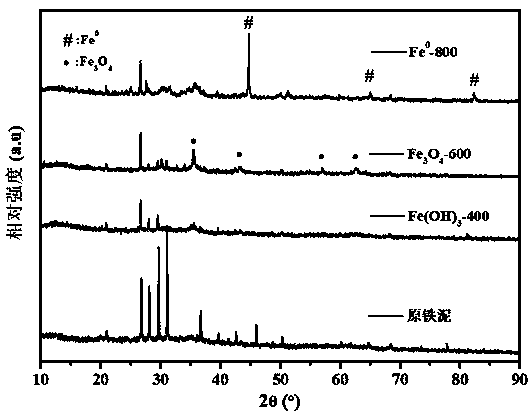

[0025] Specific embodiment one: what this embodiment records is a kind of method that utilizes the iron-containing sludge of water purification plant to prepare nanometer zero-valent iron, and the specific steps of described method are as follows:

[0026] Step 1: Pretreatment of iron-containing sludge: first, air-dry the iron-containing sludge naturally to a moisture content of 5% to 10%, then pulverize it, and then put the pulverized sludge into a blast drying box. Dry at 105°C for 24 hours, then further grind and sieve through 200 mesh to obtain a dry sludge sample; the source of the iron-containing sludge is: the coagulation / flocculation treatment unit of the water purification plant uses iron salt ( Contains ferric chloride, ferric sulfate, polyferric chloride, polyferric aluminum chloride and other iron-containing reagents) as a flocculant, after coagulation-sedimentation treatment to obtain high-concentration muddy water, then add polyacrylamide, stir and centrifuge and ...

specific Embodiment approach 2

[0028] Embodiment 2: In Embodiment 1, a method for preparing nanometer zero-valent iron using iron-containing sludge from a water purification plant, in step 2, the inert gas is argon.

specific Embodiment approach 3

[0029] Specific embodiment three: a method for preparing nano-zero-valent iron from the iron-containing sludge of a water purification plant described in specific embodiment one or two, in step two, the flow rate of the inert gas or nitrogen is 160 mL / min ; During the calcination process, the flow rate of inert gas or nitrogen was 100 mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com