Production method of flour special for low-bacterial raw and wet flour products

A technology for a raw wet noodle product and a production method, which is applied in the field of flour processing, can solve the problems of high microbial content, excessive microorganisms, microbial spoilage and deterioration of raw wet noodle products, and achieves good sensory evaluation, not easy to browning, and low cooking loss rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

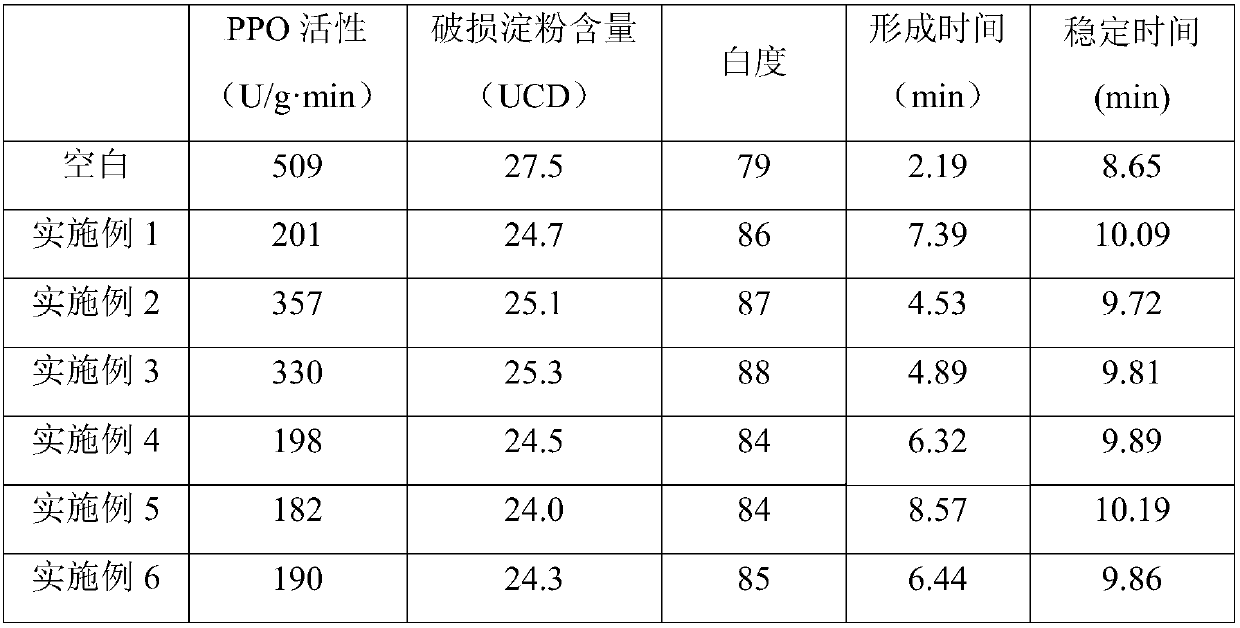

Examples

Embodiment 1

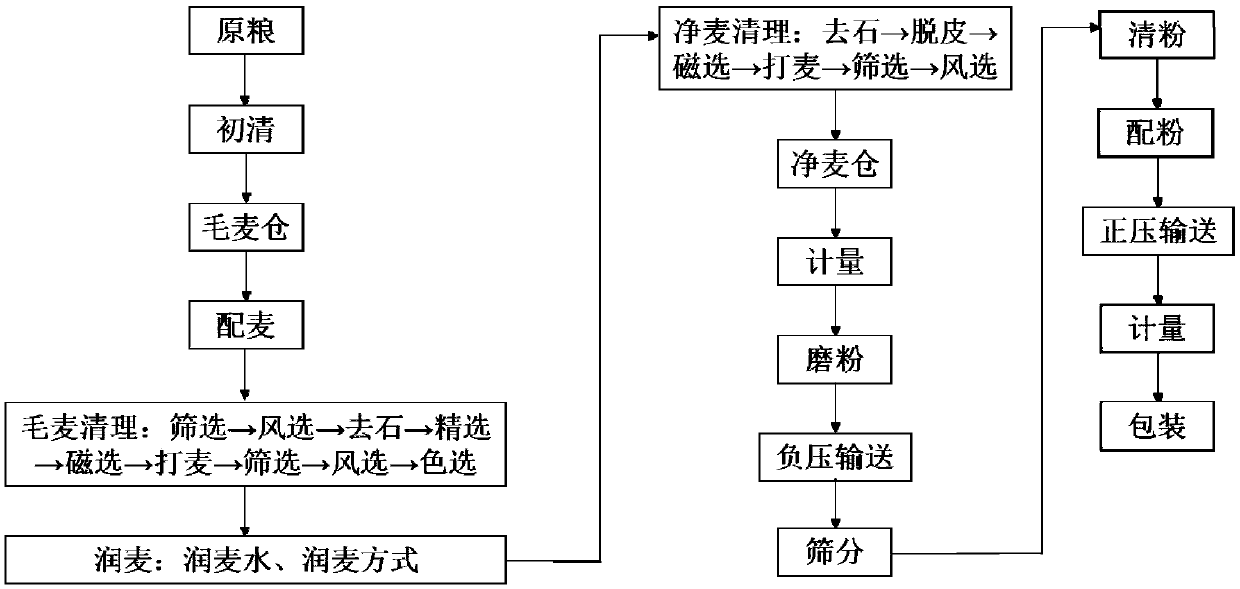

[0052] The processing technology of the special powder for low-bacteria raw wet noodles of the present embodiment comprises the following steps:

[0053] (1) Primary cleaning of mixed wheat, including two screenings, two winnowings, one selection, one threshing and one color sorting, specifically including wool wheat → screening → winnowing → stone removal → selection → magnetic separation → Wheat → screening → winnowing → color sorting;

[0054] (2) Condition the wheat cleaned in (1), use 70ppm, slightly acidic electrolyzed water with a pH of 5.8 to adjust the moisture content of the wheat grains to 14.0wt%, and then combine steam conditioning at 135°C for 2 minutes, Equilibrate at 25°C for 8 hours, and finally the moisture content of wheat grains reaches 16.0%;

[0055] (3) Cleaning the moistened wheat in (2) again, including one step of peeling, one step of threshing, one step of screening and one step of winnowing, specifically including stone removal → peeling → magnetic...

Embodiment 2

[0061] The processing technology of the special powder for low-bacteria raw wet noodles of the present embodiment comprises the following steps:

[0062] (1) Primary cleaning of mixed wheat, including two screenings, two winnowings, one selection, one threshing and one color sorting, specifically including wool wheat → screening → winnowing → stone removal → selection → magnetic separation → Wheat → screening → winnowing → color sorting;

[0063] (2) Conditioning the wheat cleaned in (1), using 70ppm, slightly acidic electrolyzed water with a pH of 5.8 combined with vibratory conditioning at 25°C for 8 hours, and adjusting the moisture content of the wheat grains to 16.0wt%;

[0064] (3) Cleaning the moistened wheat in (2) again, including one step of peeling, one step of threshing, one step of screening and one step of winnowing, specifically including stone removal → peeling → magnetic separation → threshing → screening → winnowing, wherein Peeling is to use RCMTK series fl...

Embodiment 3

[0070] (1) Primary cleaning of mixed wheat, including two screenings, two winnowings, one selection, one threshing and one color sorting, specifically including wool wheat → screening → winnowing → stone removal → selection → magnetic separation → Wheat → screening → winnowing → color sorting;

[0071] (2) Condition the wheat after cleaning in (1), use 10mg / L, ozone water at 0°C combined with vibrating tempering at 25°C for 9 hours, and adjust the moisture content of the wheat grains to 16.0wt% ;

[0072] (3) Cleaning the moistened wheat in (2) again, including one step of peeling, one step of threshing, one step of screening and one step of winnowing, specifically including stone removal → peeling → magnetic separation → threshing → screening → winnowing, wherein Dehulling is to adopt the FBPY wheat multi-component gradual pressure rotary peeling machine to remove 3wt% of the wheat cortex;

[0073] (4) Transport the wheat obtained in (3) to the flour room for processing, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash | aaaaa | aaaaa |

| Ash | aaaaa | aaaaa |

| Ash | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com