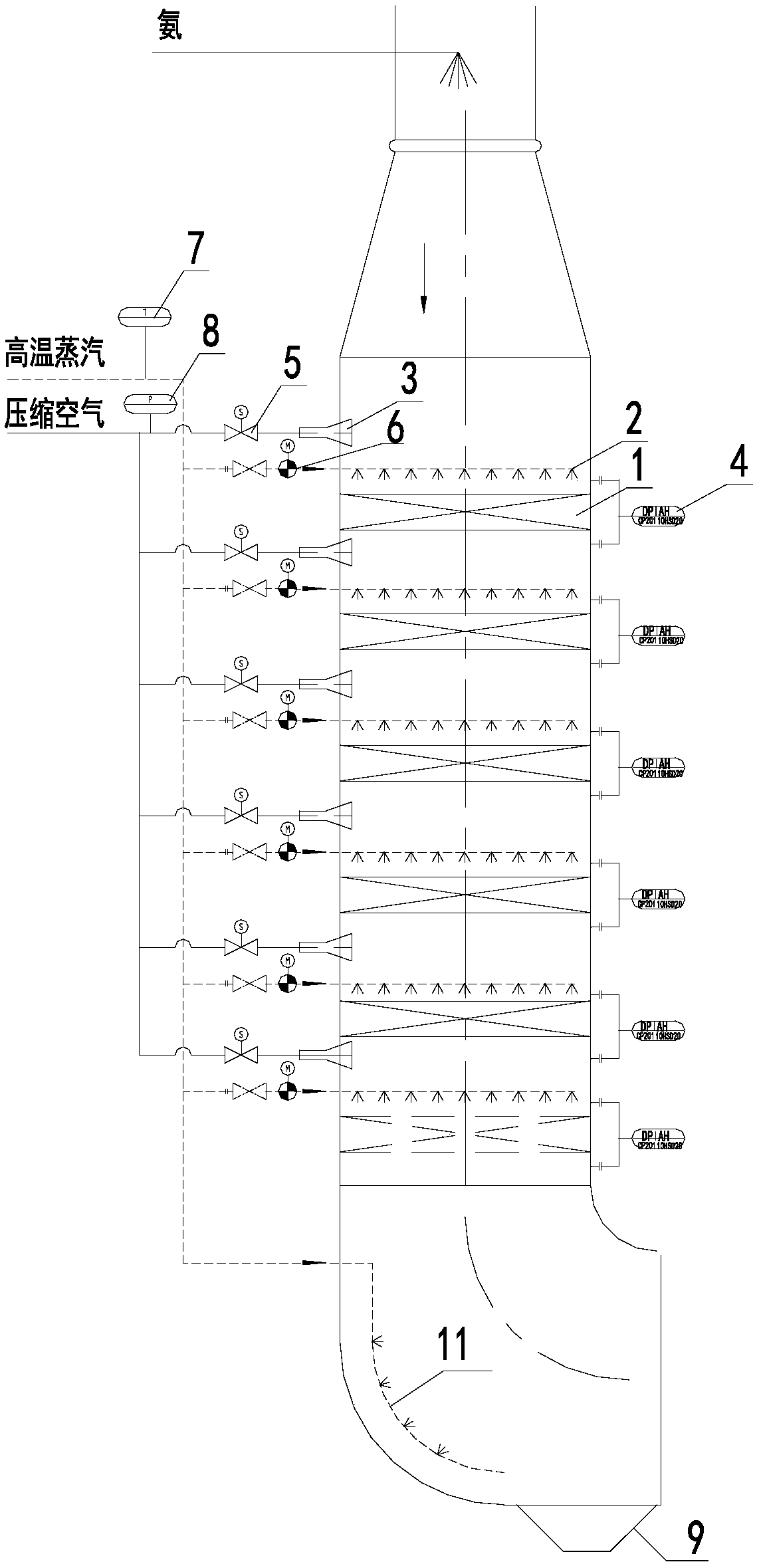

SCR denitration method and device with combined soot blowing function

An SCR reactor and denitrification technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of large temperature drop of compressed air, high energy consumption, and large steam consumption, and achieve comprehensive energy consumption reduction, Improve system stability and energy saving, and enhance the effect of soot blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

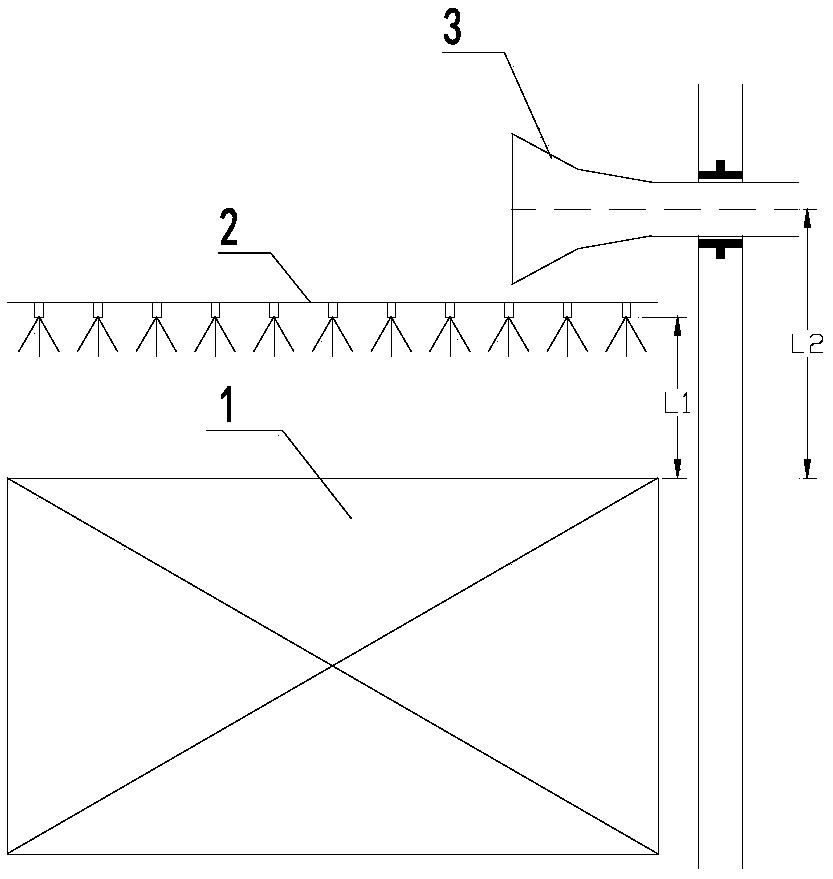

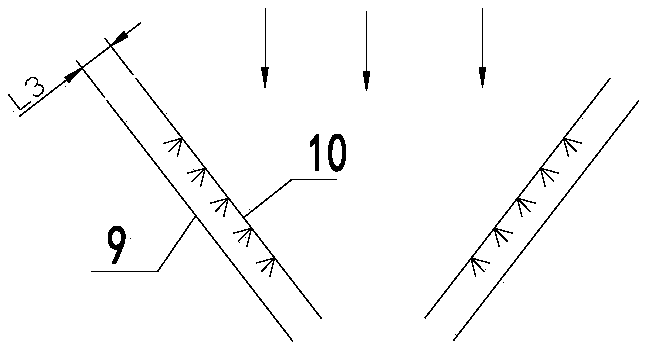

[0062] The SCR flue gas denitrification device of the cement kiln is arranged downstream of the C1-level cyclone preheater (that is, the high-dust arrangement), and the flue gas entering the SCR reactor is 10000Nm 3 / h, smoke concentration 60-80g / m 3 , the temperature is 300-340°C, the SCR reactor is arranged vertically, and there are 5 layers of catalysts in total. The upper part of each catalyst layer is equipped with a steam soot blower, the steam is led from the waste heat boiler, the steam temperature is 340°C, the gas source of each sonic soot blower is controlled by an electric valve, and the purge hole of the rake steam soot blower is 400mm away from the upper surface of the catalyst. A sonic sootblower is arranged on the upper part of the rake sootblower. The center line of the bell mouth of the sonic sootblower is 750mm away from the upper surface of the catalyst. The air source of the sonic sootblower is compressed air, controlled by a solenoid valve, and the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com