Defoaming agent for metal cutting processing fluid and preparation method of defoaming agent

A technology for metal cutting and processing fluids, which is applied in the field of metal cutting and processing fluid defoamers and their preparations, can solve problems such as inability to sustain defoaming and antifoaming, decrease in defoaming and antifoaming properties, and decline in defoaming and stability. Enhanced compatibility and stability, enhanced defoaming and anti-foaming properties, and excellent anti-foaming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

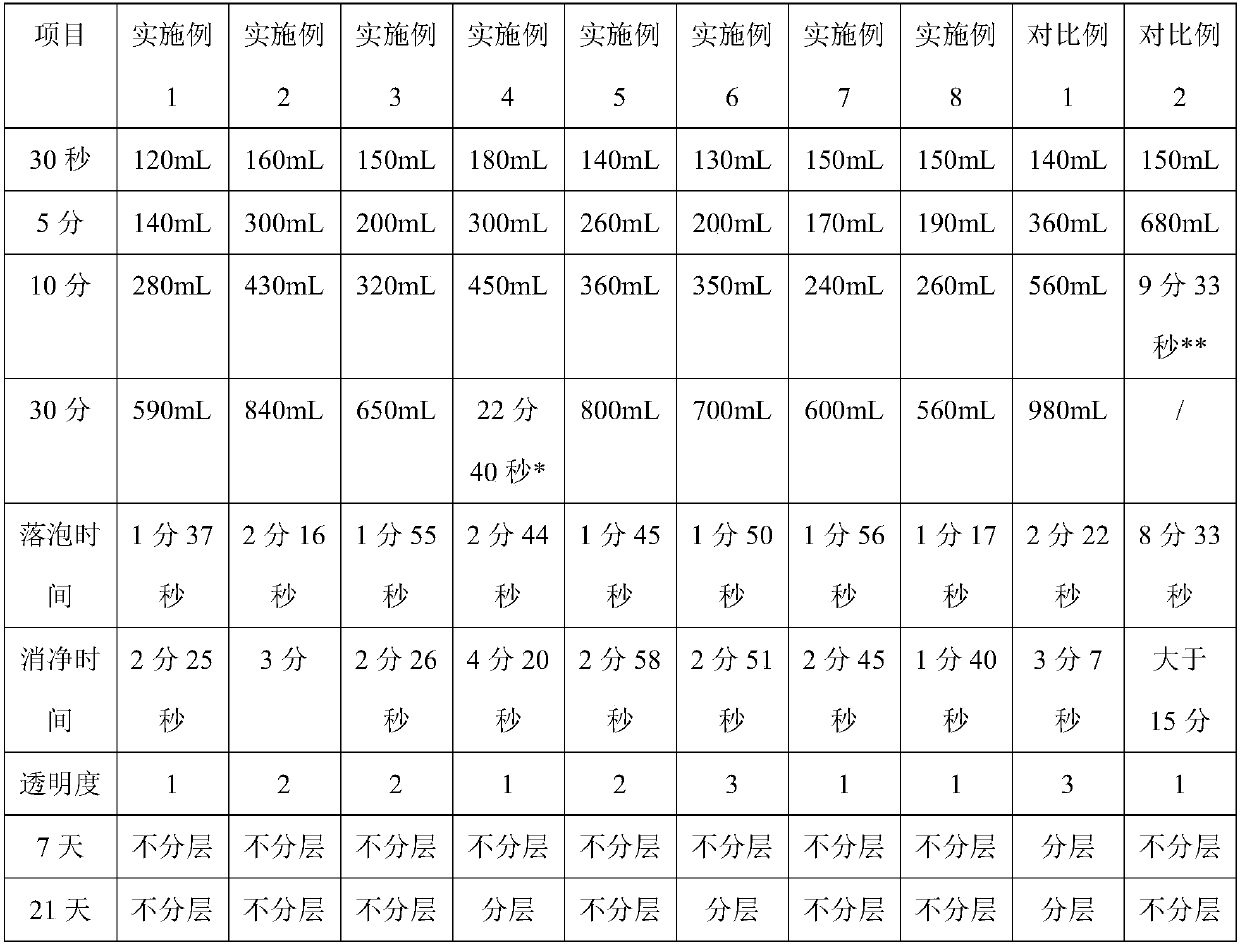

Examples

Embodiment 1

[0044] 25.07g of hydrogen-containing silicone oil with a hydrogen content of 0.22%, Mn=7000 (Mn represents the number average molecular weight, the same below), 114.6g of polyether CH 2 =CHCH 2 O(EO) 2 (PO) 25 OB (B, butyl, represents butyl, i.e. butyl-terminated polyether, hereinafter the same), 5.66g eicosene and 0.073g catalyst (chloroplatinic acid isopropanol solution, hereinafter the same) are added to the reaction flask; Nitrogen gas was introduced, and the reaction was carried out at 100° C. for 5 h to obtain a colorless and transparent alkyl and polyether co-modified silicone oil 1 .

[0045] Stir and mix 15g of silicone grease LAC-003 (transfer chemical industry, the same below), 20g of alkyl and polyether co-modified silicone oil 1, and 5g of emulsifier at 80°C, then cool with ice-water mixture, and add 60g of water Phase inversion emulsification was carried out to obtain milky white metal cutting fluid defoamer 1.

Embodiment 2

[0047] 20g of hydrogen-containing silicone oil with a hydrogen content of 0.18% and Mn=10000, 22.76g of polyether CH 2 =CHCH 2 O(EO) 8 (PO) 15 OH, 22.76g polyether CH 2 =CHCH 2 O(EO) 16 (PO) 16 Add OH, 3.97g of a mixture of eicosine to tetracosene and 0.035g of a catalyst into the reaction flask; blow nitrogen into it, and react at 110°C for 4 hours to obtain light yellow and transparent alkyl and polyether co-modified silicone oil 2.

[0048] Stir and mix 12g of silicone grease LAC-003, 21g of alkyl and polyether co-modified silicone oil 2 and 4g of emulsifier at 90°C, then cool at 5°C, add 63g of water for phase inversion emulsification, and obtain milky white Metal cutting fluid defoamer 2.

Embodiment 3

[0050] 20g of hydrogen-containing silicone oil with a hydrogen content of 0.18% and Mn=10000, 48.89g of polyether CH 2 =CHCH 2 O(EO) 6 (PO) 26 OH, 16.30g polyether CH 2 =CHCH 2 O(EO) 5 (PO) 15 OH and 0.0426g of catalyst were added to the reaction flask; nitrogen gas was introduced, and the reaction was carried out at 105°C for 4.5h to obtain colorless and transparent polyether-modified silicone oil 3.

[0051] Stir and mix 16g of silicone grease LAC-003, 22g of polyether co-modified silicone oil 3 and 3g of emulsifier at 85°C, then cool at 8°C, add 59g of water for phase inversion emulsification, and obtain milky white metal cutting liquid defoamer3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com