Non-silicon defoaming agent and preparation method thereof

A non-silicon defoamer and defoamer technology, applied in the field of non-silicon defoamer and its preparation, can solve the problem that product stability, defoaming performance and compatibility cannot be guaranteed at the same time, which affects the performance of the foaming system , needs to be further improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Combine 18 parts of peanut oil, 0.1 part of hydrophobic silica (with a specific surface area of 50m 2 / g) Disperse in a high-speed disperser at a speed of 1500 rpm for 20 minutes at a high speed, raise the temperature to 160° C., and keep it warm for 0.5 hours to obtain a mixture G1.

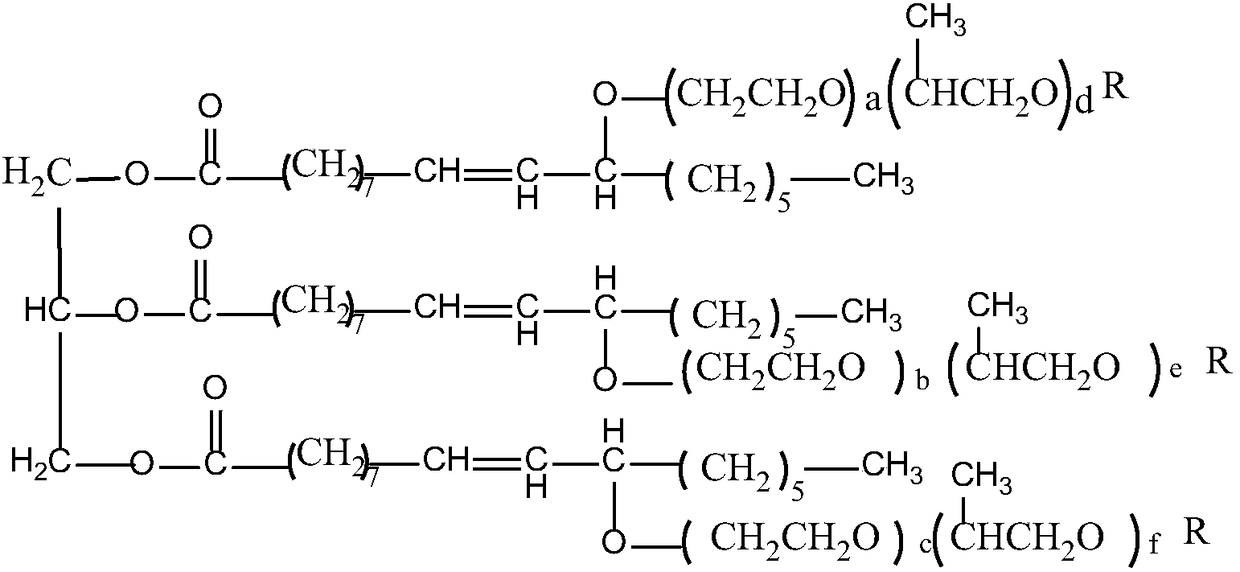

[0030] 2. Mix 13.5 parts of epoxy peanut oil, 2 parts of castor oil polyoxyethylene polyoxypropylene ether oleate (a+b+c is 0, d+e+f is 20, and both R groups are -OC (CH 2 )CH=CH(CH 2 )CH 3 ), 0.1 part of polyamide-modified hydrogenated castor oil were dispersed in a high-speed disperser at 2000 rpm at high speed and heated to 50° C., kept for 0.5 h to obtain mixture H1.

[0031]3. Put the mixture G1, 18 parts of epoxidized peanut oil, 0.1 part of hydrogenated castor oil, and 1.7 parts of aluminum stearate into the container and start stirring. Stir at room temperature for 30 minutes to disperse the system evenly, and then slowly heat up to 180°C. And keep it warm for 0.5h; after...

Embodiment 2

[0034] 1. First mix 7 parts of linseed oil, 5 parts of hydrophobic silica (with a specific surface area of 200m 2 / g) Disperse in a high-speed disperser at 2500 rpm for 20 minutes at a high speed, and raise the temperature to 100° C., and keep it warm for 2 hours to obtain the mixture G2.

[0035] 2. Mix 14 parts of epoxy linseed oil, 10 parts of castor oil polyoxyethylene polyoxypropylene ether oleate (a+b+c is 40, d+f+e is 0, and only R group is —OC( CH 2 )CH=CH(CH 2 )CH 3 ), 1.5 parts of polyamide-modified hydrogenated castor oil were dispersed in a high-speed dispersant at 1000 rpm at a high speed, and the temperature was raised to 40° C., and kept for 1 hour to obtain a mixture H2.

[0036] 3. Put the mixture G2, 21 parts of linseed oil, 3.5 parts of polyamide-modified hydrogenated castor oil, and 5 parts of magnesium stearate into the container and start stirring. Stir at room temperature for 10 minutes to disperse the system evenly, and then slowly heat up to 140°C...

Embodiment 3

[0039] 1. First, 17 parts of rapeseed oil, 1.8 parts of hydrophobic silica (specific surface area of 100m 2 / g) Disperse in a high-speed disperser at 2000 rpm for 15 minutes at a high speed, raise the temperature to 130° C., and keep it warm for 1 hour to obtain mixture G3.

[0040] 2. Mix 8.5 parts of soybean oil, 3 parts of polyoxyethylene polyoxypropylene ether oleate (d+e+f is 10, a+b+c is 20, and only the R group is -OC(CH 2 )CH=CH(CH 2 )CH 3 ), 0.04 parts of hydrogenated castor oil were dispersed in a high-speed dispersant at 1500 rpm at a high speed, and the temperature was raised to 45° C., and kept for 0.8 h to obtain a mixture H3.

[0041] 3. Put the mixture G3, 21.25 parts of rapeseed oil, 0.06 parts of hydrogenated castor oil, and 0.1 part of calcium stearate into the container and start stirring. Stir at room temperature for 20 minutes to disperse the system evenly, and then slowly heat up to 160°C. And keep it warm for 2 hours; after the heat preservation is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com