Method for deironing through nickel-containing leaching liquid comprehensive treatment

A comprehensive treatment and leaching solution technology, which is applied in the direction of photography technology, equipment, photography auxiliary technology, etc., can solve the problems of high cost and long nickel ore treatment process, and achieve the effects of improving quality, strong antimagnetic, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further limited below in conjunction with specific embodiments, but the scope of protection is not limited to the descriptions made.

[0021] In the following embodiments, the anode is made of magnetic materials (such as electromagnets, permanent magnets), and the cathode is made of stainless steel; especially, magnetic materials resistant to alkali corrosion and electrochemical corrosion are used.

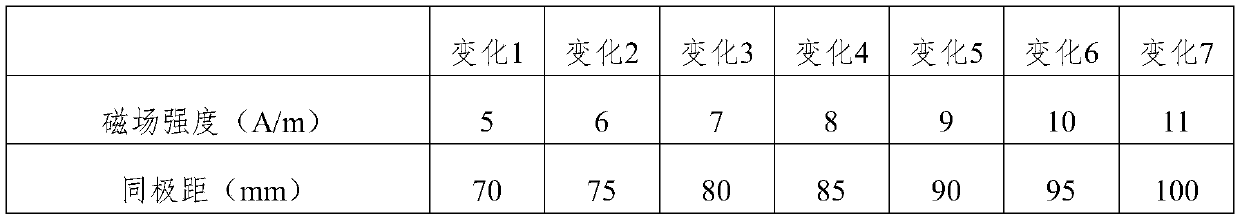

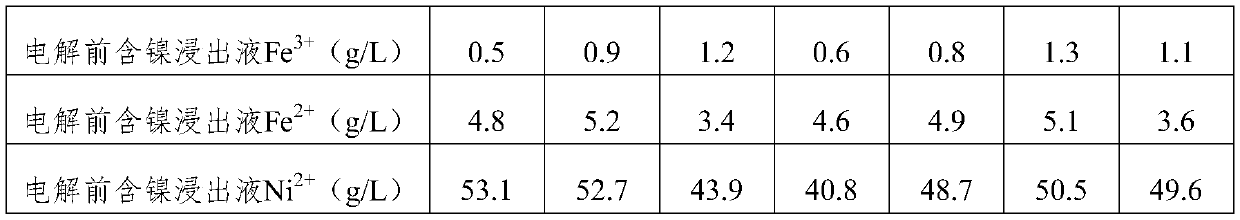

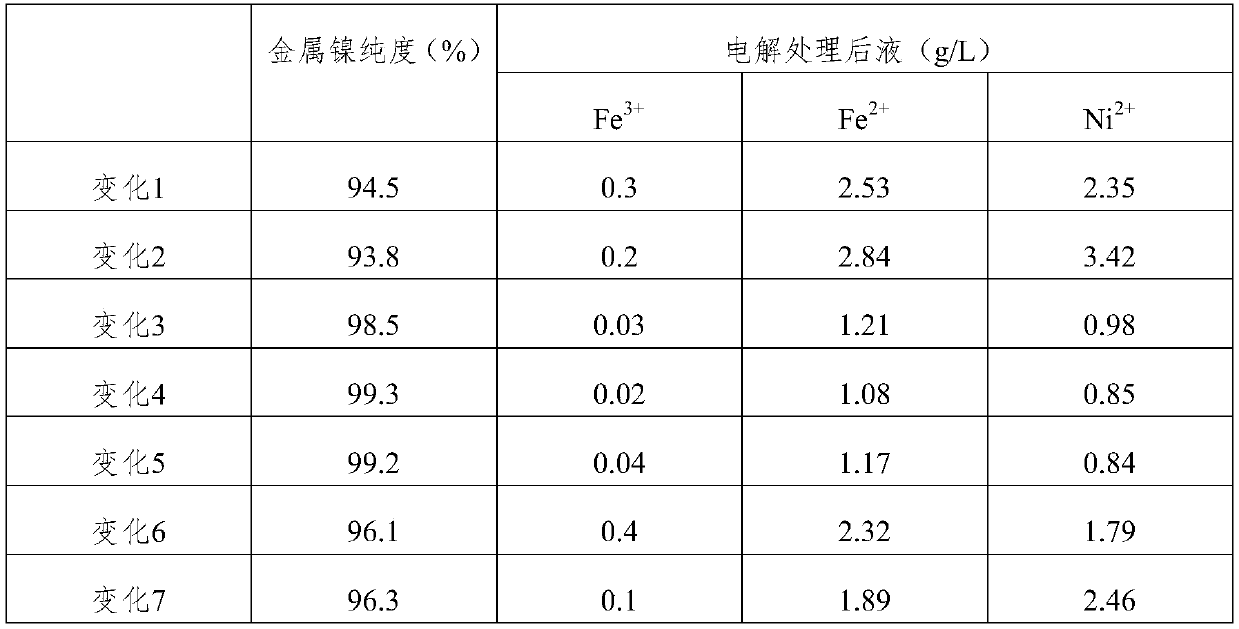

[0022] In the following test treatment process, the test treatment methods are carried out in accordance with the following methods:

[0023] The electrolytic cell for electrolyzing the nickel-containing leaching solution is separated into an anode area and a cathode area by a diaphragm; the anode area is equipped with an electrolytic cell anode, and the cathode area is equipped with an electrolytic cell cathode; the electrolysis conditions adopt a voltage of 3-3.5V and a current density of 500-1000A / m 2 , the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com