A kind of method of producing L-leucine by fermentation

A technology for producing leucine and bacteria, which is applied in the field of fermentative production of L-leucine, which can solve the problems of low L-leucine yield, complex extraction process, and low sugar-acid conversion rate, etc., to improve the sugar-acid conversion rate , Optimizing the medium, improving the effect of yield and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

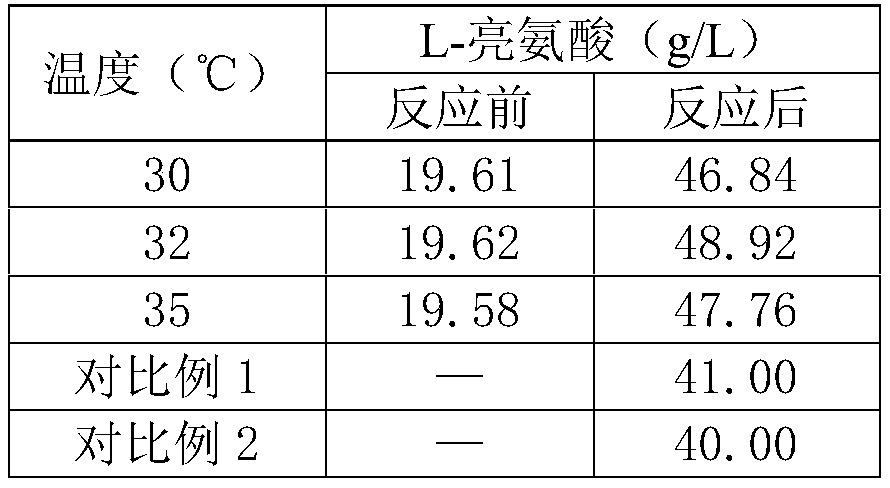

[0044] Embodiment 1: A kind of method of fermentative production L-leucine

[0045] The difference from the basic example is that the fermentation culture temperature in step (3) is 32°C, the ventilation rate for the first 12 hours is 90 L / h, the ventilation rate after 12 hours is 110 L / h, and the elution flow rate in step (4) is 0.5 BV / h. Feed 2 times during fermentation, the feed medium used: sodium malate 1.0g / L, inositol 1.5g / L, corn steep liquor powder 12g / L, ammonium sulfate 25g / L, KH 2 PO 4 ·3H 2 O2.0g / L, MgSO 4 ·7H 2 O 0.6g / L, MnSO 4 ·H 2 O 0.3g / L, vitamin B1 400μg / L, biotin 60μg / L, CaCO 3 20g / L, defoamer 1.0%, pH=7.0-7.2.

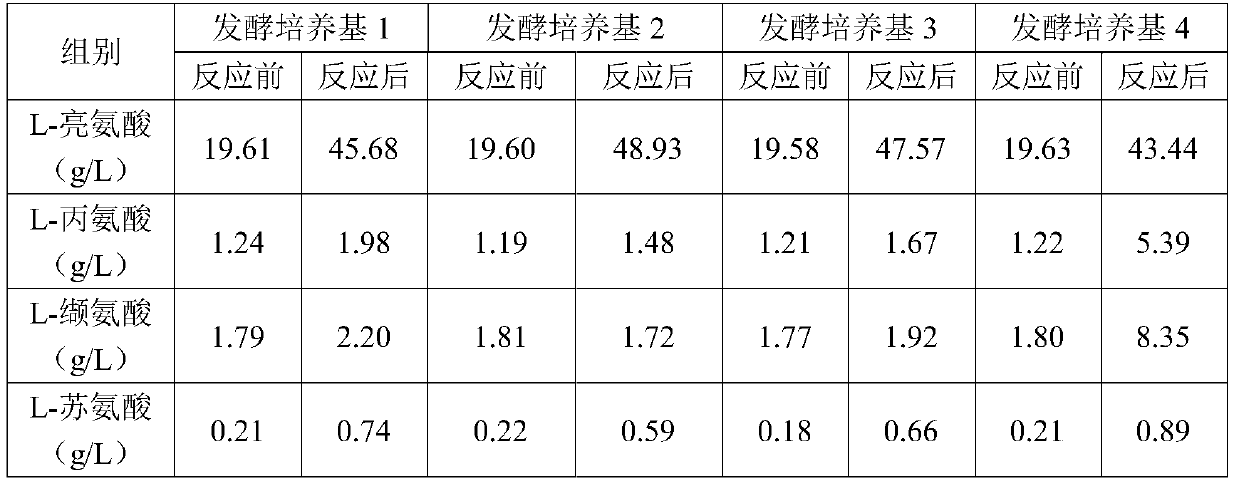

[0046] The following four mediums were used for fermentation culture:

[0047] Fermentation medium 1: sodium malate 2.0g / L, anhydrous glucose 140g / L, corn steep liquor powder 35g / L, ammonium sulfate 20g / L, KH 2 PO 4 ·3H 2 O 1.0g / L, MgSO 4 ·7H 2 O 0.4g / L, MnSO 4 ·H 2 O 0.1g / L, vitamin B1 300μg / L, biotin 50μg / L, CaCO 3 30g / L, 0.5% d...

Embodiment 2

[0055] Embodiment 2: A kind of method of fermentative production L-leucine

[0056] The difference from the basic example is that the fermentation culture temperature in step (3) is 32°C, the ventilation rate for the first 12 hours is 90 L / h, the ventilation rate after 12 hours is 110 L / h, and the elution flow rate in step (4) is 0.5 BV / h, the fermentation medium used includes: sodium malate 3.0g / L, anhydrous glucose 150g / L, corn steep liquor powder 35g / L, ammonium sulfate 20g / L, KH 2 PO 4 ·3H 2 O 1.0g / L, MgSO 4 ·7H 2 O 0.4g / L, MnSO 4 ·H 2 O 0.1g / L, vitamin B1 300μg / L, biotin 50μg / L, CaCO 3 30g / L, 0.5% defoamer, pH=7.0-7.2. Feed 2 times during the fermentation period, respectively use the following feed medium for feeding:

[0057] Feed medium 1: sodium malate 1.0g / L, inositol 1.0g / L, corn steep liquor powder 12g / L, ammonium sulfate 25g / L, KH 2 PO 4 ·3H 2 O 2.0g / L, MgSO 4 ·7H 2 O 0.6g / L, MnSO4·H2O 0.3g / L, vitamin B1 400μg / L, biotin 60μg / L, CaCO3 20g / L, defoamer 1...

Embodiment 3

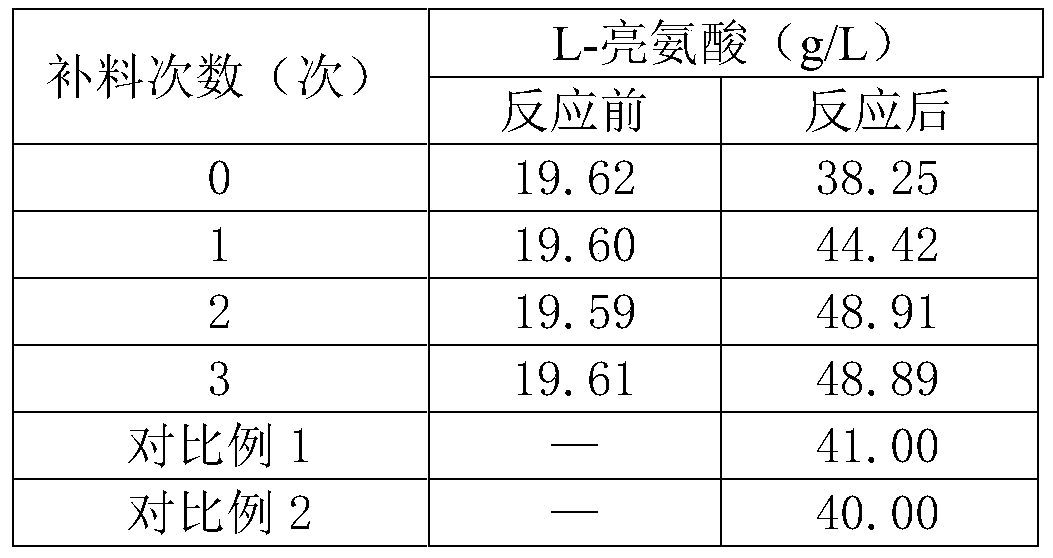

[0064] Embodiment 3: A kind of method of fermentative production L-leucine

[0065] The difference from the basic example is that the fermentation culture temperature in step (3) is 32°C, the ventilation rate for the first 12 hours is 90 L / h, the ventilation rate after 12 hours is 110 L / h, and the elution flow rate in step (4) is 0.5 BV / h, the fermentation medium used includes: sodium malate 3.0g / L, anhydrous glucose 150g / L, corn steep liquor powder 35g / L, ammonium sulfate 20g / L, KH 2 PO 4 ·3H 2 O 1.0g / L, MgSO 4 ·7H 2 O 0.4g / L, MnSO 4 ·H 2 O 0.1g / L, vitamin B1 300μg / L, biotin 50μg / L, CaCO 3 30g / L, 0.5% defoamer, pH=7.0-7.2. The feed medium used: sodium malate 1.0g / L, inositol 1.5g / L, corn steep liquor dry powder 12g / L, ammonium sulfate 25g / L, KH 2 PO 4 ·3H 2 O 2.0g / L, MgSO 4 ·7H 2 O 0.6g / L, MnSO 4 ·H 2 O 0.3g / L, vitamin B1 400μg / L, biotin 60μg / L, CaCO 3 20g / L, defoamer 1.0%, pH=7.0-7.2. The times of adding feed medium were 0 time, 1 time (1 time at 12h), 2 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com