Olefin oxidizing method

An olefin and oxidant technology, applied in chemical instruments and methods, chemical industry, organic chemistry, etc., can solve the problems of large fluctuations in catalyst activity and selectivity, reduced catalyst activity and selectivity, catalyst deactivation, etc. Effectiveness of utilization, no oxidant residue, high oxidant conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

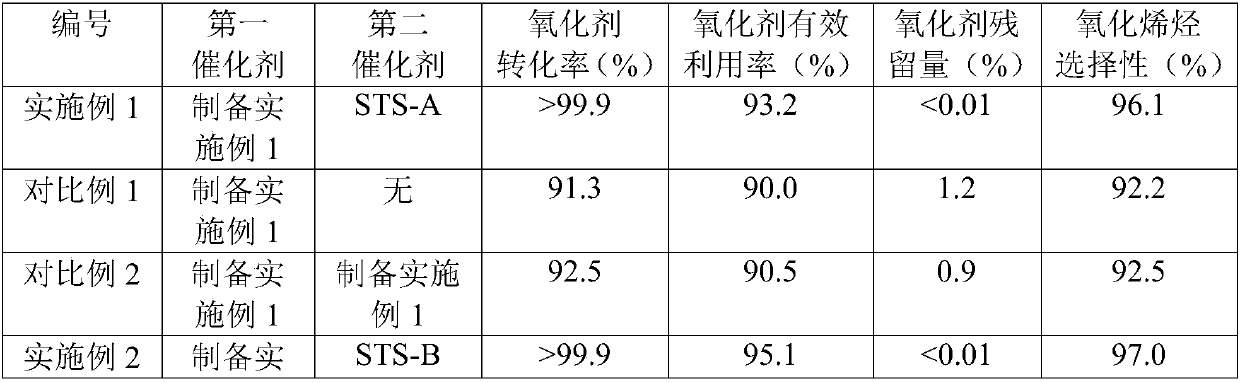

Examples

preparation example Construction

[0023] In a preferred embodiment of the present invention, the preparation method of the shaped first catalyst comprises: under hydrolysis reaction conditions, at least one organosilicon compound capable of hydrolysis reaction and at least one water-soluble base and water Contacting, mixing the contacted mixture with titanium-silicon molecular sieves, and successively molding and roasting the obtained mixture containing titanium-silicon molecular sieves. The shaped first catalyst obtained according to this embodiment not only has higher strength and thus is more resistant to wear and crushing, the bed containing the catalyst has a higher resistance to collapse; and it is possible to obtain Higher oxidant conversion and oxidized olefin selectivity.

[0024]In this preferred embodiment, the amount of the organosilicon compound, the water-soluble base and the titanium-silicon molecular sieve should be used to form the titanium-silicon molecular sieve, and the amount of water shou...

Embodiment approach A

[0045] Therefore, according to a preferred embodiment A of the present invention, the titano-silicon-alumina molecular sieve is prepared according to the following steps:

[0046](1) Mix the unloading agent with the organic acid solution for beating, and perform the first heat treatment on the obtained slurry to separate and obtain the first solid with a relative crystallinity of 70-90%, wherein the unloading agent is obtained from titanium silicon Molecular sieve is discharged from the reaction device as the active component of the catalyst;

[0047] (2) The second heat treatment is performed after mixing the first solid, the aluminum source, the optional titanium source and the alkali source in the presence of an aqueous solvent. Wherein, the titanium source is a selectively used component.

[0048] In the preferred embodiment A of the present invention, the unloading agent of the reaction device using titanium-silicon molecular sieve as the catalyst active component can be...

Embodiment approach B

[0080] The inventors of the present invention further found that if the deactivated silica-alumina molecular sieve is contacted with an organic acid, etc., a titanium-silicon-alumina molecular sieve with better olefin oxidation effect can also be obtained. Therefore, according to another preferred embodiment B of the present invention, The titano-silicon-alumina molecular sieve is prepared according to the following steps:

[0081] (a) mixing the unloading agent with the organic acid solution for beating, and subjecting the resulting slurry to a first heat treatment to separate and obtain a first solid with a relative crystallinity of 50-70%, wherein the unloading agent is obtained from silica-alumina Molecular sieve is discharged from the reaction device as the active component of the catalyst;

[0082] (b) performing a second heat treatment after mixing the first solid, optional aluminum source, titanium source and alkali source in the presence of an aqueous solvent. Wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com