Mineral insulated cable assembly

A technology of mineral insulated cables and components, applied in the direction of electrical components, circuits, two-component connection devices, etc., can solve problems such as easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

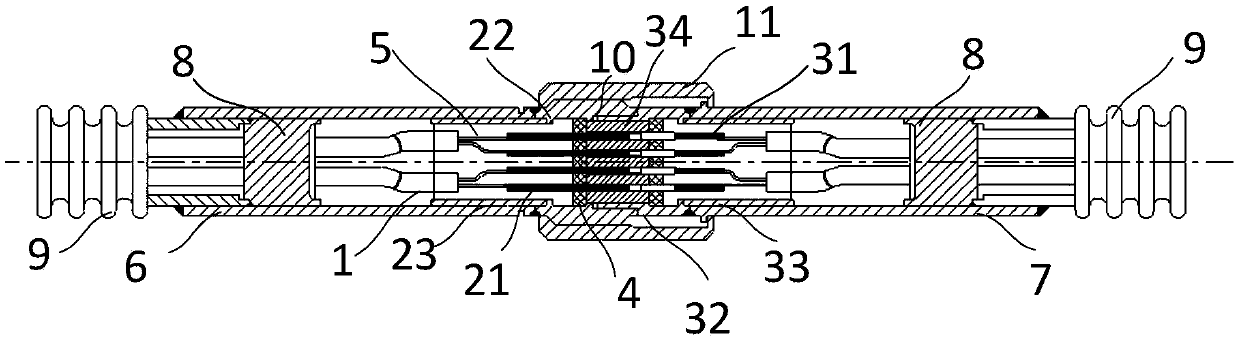

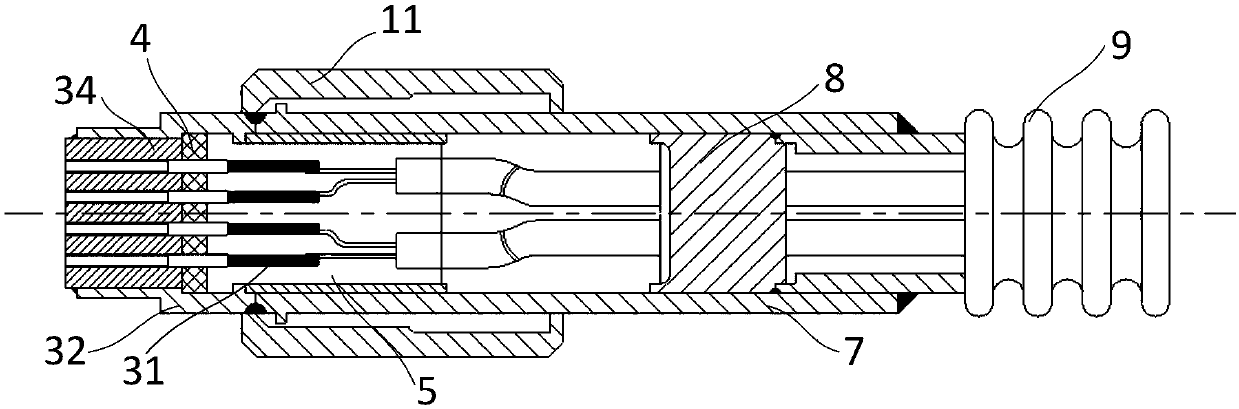

[0063] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0064] Such as figure 1As shown, the present invention provides a mineral insulated cable assembly, which includes several cables 1, and the cables 1 use inorganic mineral insulated 2-core cables. The cable 1 in this embodiment is not limited to inorganic mineral insulated 2-core cables, and other inorganic mineral insulated 1-core or multi-core cables can also be used to meet the smaller bending radius requirements and facilitate the branching of mineral insulated cable assemblies . Cut the cable 1 using a point-type or line-type laser machine. After cutting, the end of the cable 1 is covered with a stainless steel sleeve slightly larger than the outer diameter of the cable 1. The end of the core wire of the cable 1 protrudes from the sleeve. Then the casing is filled with inorganic glass powder 5 for hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com