Flexible battery

A battery, a battery technology, used in battery electrodes, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of decreased electronic conductivity, separation, insufficient flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific embodiments are described in detail below, so that it is easier to understand the purpose, technical content, characteristics and effects of the present invention.

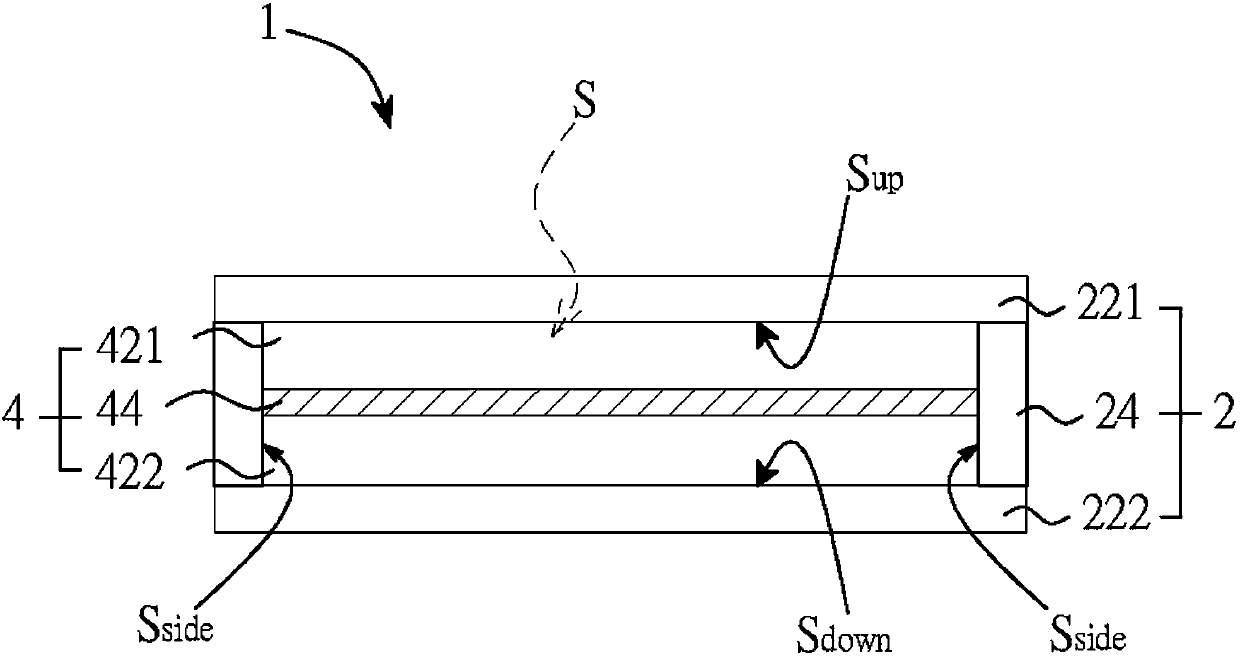

[0055] Please see first figure 1 . The flexible battery 1 includes an electrochemical reaction structure 4 and a packaging structure 2. The packaging structure 2 is a sealed structure, and its shape can be a bag, a box or any container. The packaging structure 2 includes There are two current collecting substrates 221, 222 and a plastic frame 24, the current collecting substrates 221, 222 are arranged corresponding to each other, and the plastic frame 24 is along the periphery of at least one of the current collecting substrates 221 or 222 in the orthographic projection direction. set, and at the same time directly or indirectly bonded to the above two collector substrates 221 and 222, so that the plastic frame 24 is sandwiched between the two collector substrates 221, 222 and the two collecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com