Lipid-rich chlorella and culture application thereof

A chlorella and oil technology, applied in the fields of biotechnology and bioenergy, can solve problems such as poor nitrogen fixation effect, achieve the effects of alleviating the problem of the greenhouse effect, solving the source of oil, and high fixation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Separation and domestication screening to obtain Chlorella SF-B1

[0024] (1) Obtaining the starting algae strain: In October 2011, 50mL of water samples were retrieved from Suifenhe, Heilongjiang, and inoculated into 200mL of BG11 medium for enrichment culture. The light-dark cycle is 24 hours, and the light-dark time ratio is 14:10. After culturing for about half a month, the culture medium turns green. Dilute the water sample of the enrichment culture to 10 -5 times, spread it on the BG11 solid plate under sterile conditions and cultivate it. The light intensity of the culture is 5000Lux and the temperature is 25°C. After about 10 days of cultivation, green single algae appear on the plate, and the single algae is picked and dropped on the shaker flask. Cultivation, the cultivation temperature is 25°C, and the light intensity is 8000 Lux. After 8 days of cultivation, observe under a microscope to determine whether it is a pure algae species. If it is not a...

Embodiment 2

[0029] Example 2 Identification of algae strains

[0030] The DNA of the obtained SF-B1 algae cells was extracted using the CTAB method, and the 18S rDNA gene was cloned, and the 3 positive clones obtained were sent to Shanghai Sangong Company for sequencing. The results of 18S rDNA gene sequencing analysis are shown in the sequence table. The 18S rDNA sequence was logged into the Genbank database for Blast comparison, and the results showed that it was consistent with Chlorella sp. There is the greatest similarity, its BLASTn value is 2619, Max index value is 99%, it can be determined that SF-B1 is Chlorella ( Chlorella sp. ).

Embodiment 3

[0031] Example 3 The cultivation and application of Chlorella SF-B1

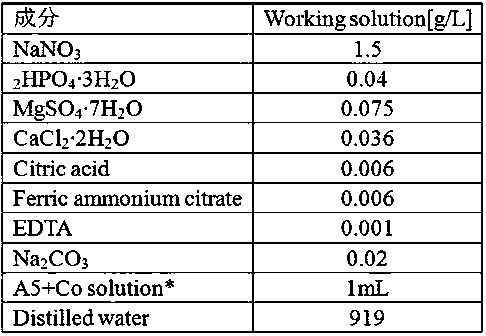

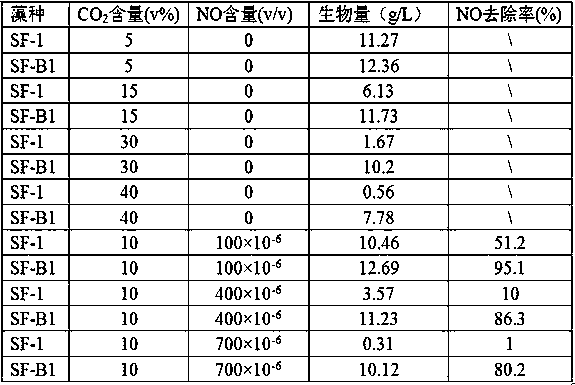

[0032] The algae liquid of SF-B1 in the logarithmic growth phase was inoculated in BG11 medium for cultivation. The formula of BG11 medium is shown in Table 1 and Table 2. The cultivation was carried out in a photobioreactor. The OD of the culture medium after inoculation was 690 is 0.2. CO was introduced from the bottom of the reactor 2 Flue gas with a content of 40v%, of which the NO content is 700×10 -6 (v / v). During the cultivation process, the light intensity was 8000Lux, the cultivation temperature was 28°C, the pH value was controlled at 7-8, the light cycle was 24h, the light-dark time ratio was 14:10, and the cultivation time was 7 days in a stable period. At the end of the cultivation, the algae fluid was collected by centrifugation, vacuum freeze-dried to constant weight at -60°C, and then the dry weight of the algae powder was measured to calculate the biomass production, and the total lipid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com