Glass detergent of cover plate glass and preparation method thereof

A technology of glass cleaning agent and cover glass, which is applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problems of easy deposition of polishing liquid, etc., and achieve high-efficiency cleaning of glass, good complexation performance, Highly safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

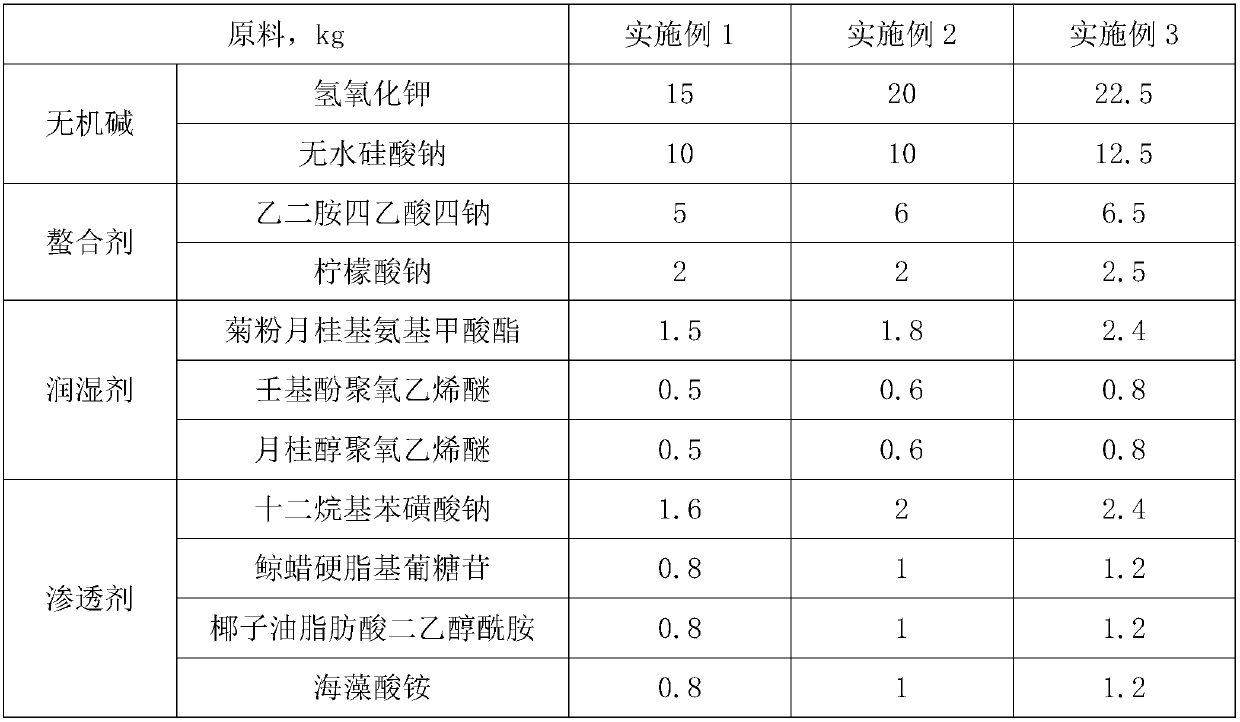

[0035] Embodiment 1: A glass cleaning agent for cover glass is prepared by the following method:

[0036] S1: Potassium hydroxide 15kg, anhydrous sodium silicate 10kg, sodium dodecylbenzenesulfonate 1.6kg, cetearyl glucoside 0.8kg, coconut oil fatty acid diethanolamide 0.8kg, ammonium alginate 0.8kg , 1.5kg of inulin lauryl carbamate, 0.5kg of nonylphenol polyoxyethylene ether and 0.5kg of lauryl alcohol polyoxyethylene ether were added to 60kg of deionized water, and stirred for 30min to obtain a suspension; S2: Add Monolauryl phosphate 0.75kg, N-dodecyl diquaternary ammonium salt 0.25kg, cocamidopropyl betaine 0.25kg and ethylene glycol 4kg, continue to stir 70-80min with the speed of 300r / min, obtain glass detergent.

Embodiment 2

[0037] Embodiment 2: A glass cleaning agent for cover glass is prepared by the following method:

[0038] S1: Potassium hydroxide 20kg, anhydrous sodium silicate 10kg, sodium dodecylbenzenesulfonate 2kg, cetearyl glucoside 1kg, coconut oil fatty acid diethanolamide 1kg, ammonium alginate 1kg, inulin laurel Add 1.8kg of urethane, 0.6kg of nonylphenol polyoxyethylene ether and 0.6kg of polyoxyethylene lauryl ether into 65kg of deionized water, and stir for 35min to obtain a suspension;

[0039] S2: Add 0.9kg of monolauryl phosphate, 0.3kg of N-dodecyl diquaternary ammonium salt, 0.3kg of cocamidopropyl betaine and 5kg of glycerol to the suspension, and continue at a speed of 350r / min Stir for 75 minutes to obtain a glass cleaning agent.

Embodiment 3

[0040] Embodiment 3: A glass cleaning agent for cover glass is prepared by the following method:

[0041] S1: Potassium hydroxide 22.5kg, anhydrous sodium silicate 12.5kg, sodium dodecylbenzenesulfonate 2.4kg, cetearyl glucoside 1.2kg, coconut oil fatty acid diethanolamide 1.2kg, ammonium alginate 1.2kg, 2.4kg of inulin lauryl carbamate, 0.8kg of nonylphenol polyoxyethylene ether and 0.8kg of lauryl alcohol polyoxyethylene ether were added to 70kg of deionized water, stirred for 40min to obtain a suspension;

[0042] S2: Add 1.2kg of monolauryl phosphate, 0.4kg of N-dodecyl diquaternary ammonium salt, 0.4kg of cocamidopropyl betaine and 4 5 6 kg of propylene glycol butyl ether to the suspension, and use 400r / min Continue stirring at a high speed for 80 minutes to obtain a glass cleaning agent.

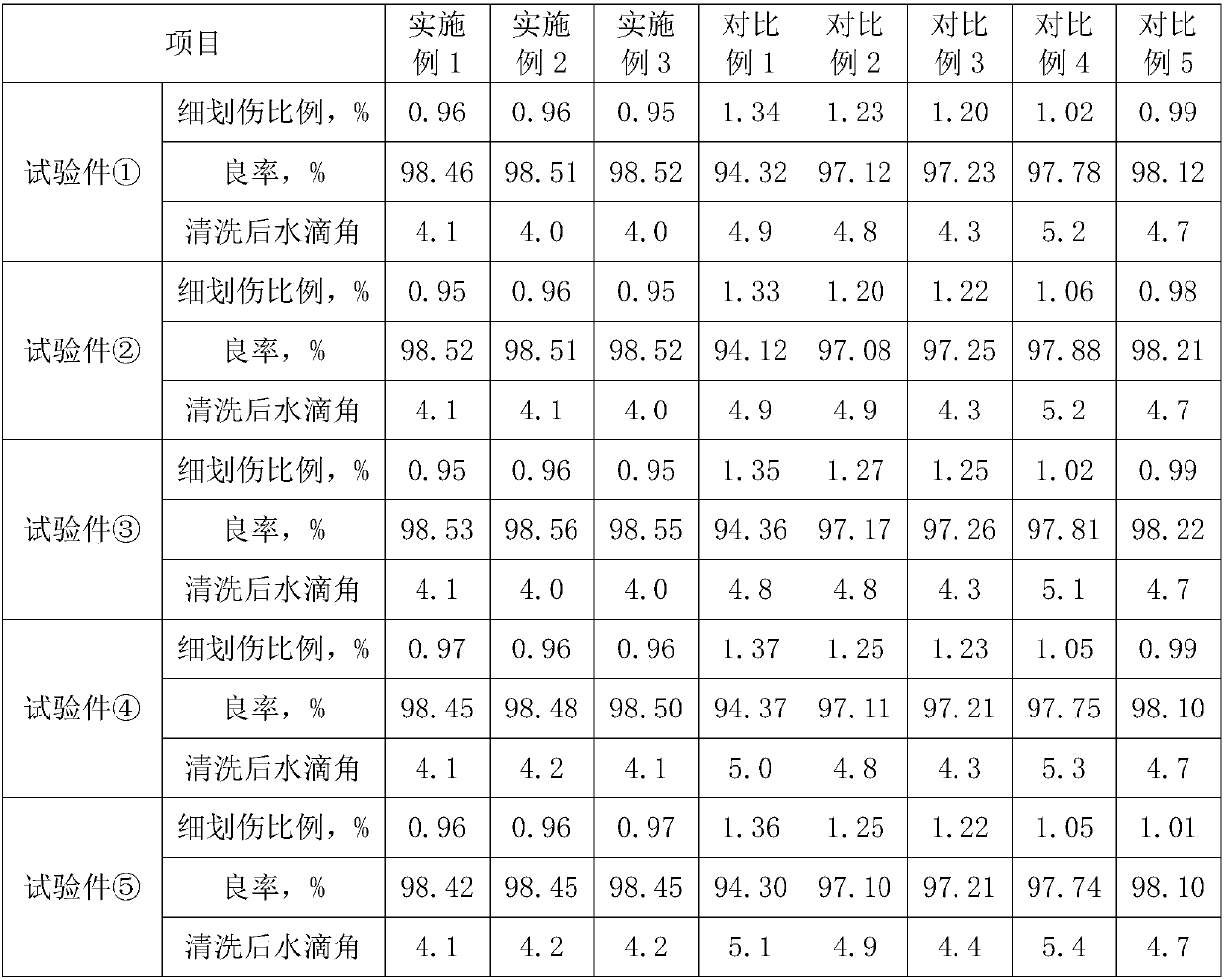

[0043] Table 1

[0044]

[0045]

[0046] 2. Comparison ratio

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com