Environment-friendly ethyl-alcohol-free fountain solution

An alcohol-free, fountain solution technology, applied in the field of fountain solution, can solve the problems of increasing the frequency of shutdown and cleaning of the printing factory, not involving alcohol-free fountain solution, hindering the fountain solution, etc., and achieves rapid reduction of dynamic surface tension and clear Evenly spreading ability, quick corner effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

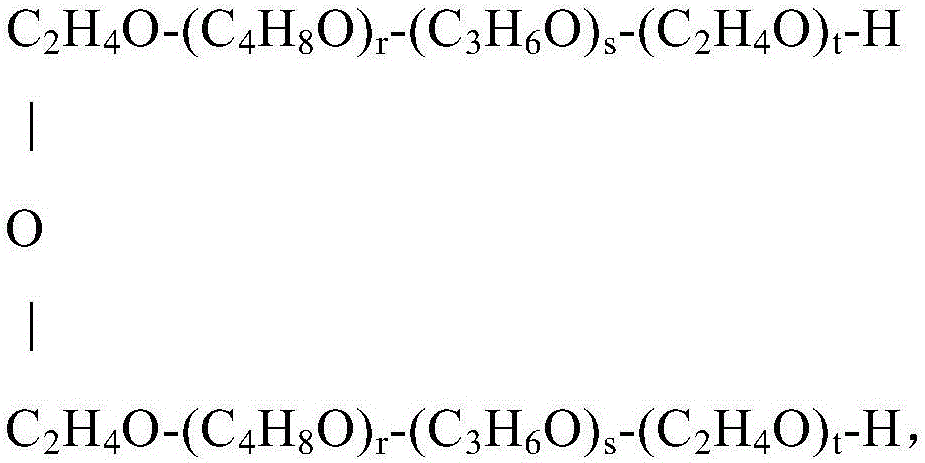

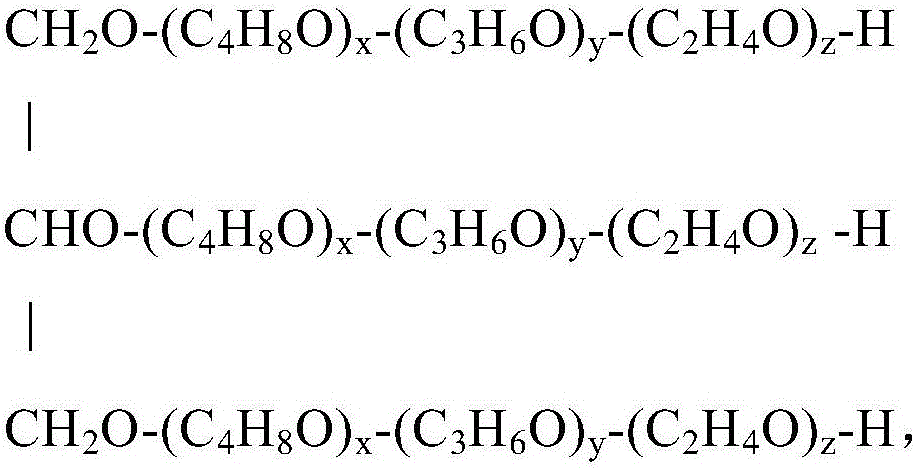

Method used

Image

Examples

Embodiment 1

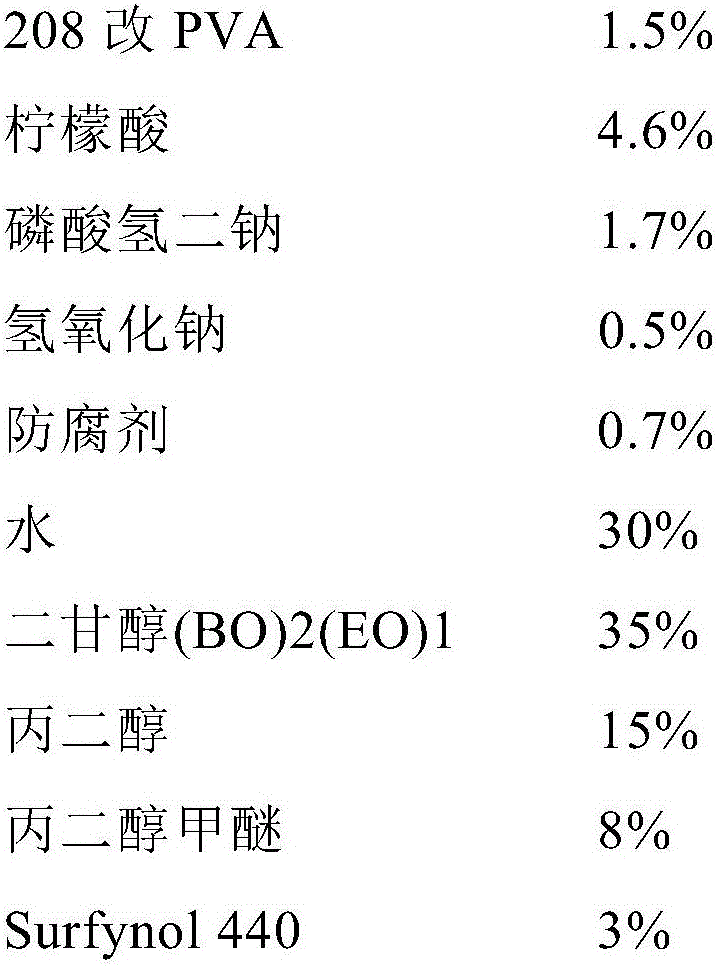

[0056] Environment-friendly alcohol-free fountain concentrate formula 1:

[0057]

[0058] Dilute the environment-friendly alcohol-free dampening solution in water at a volume ratio of 3:97, and the physical properties of the obtained environmental-friendly alcohol-free dampening solution are as follows: pH=4.22, electrical conductivity=1210 μS / cm, dynamic surface tension= 32.1dynes / cm, viscosity=1.79cps, the emulsification rate of the environment-friendly alcohol-free dampening solution of high-grade offset printing ink is: 35.8% for yellow ink, 40.9% for red ink, 41.7% for blue ink, and 41.8% for black ink. This environmentally friendly alcohol-free fountain solution has been used on press for two weeks with no problems.

Embodiment 2

[0060] Environment-friendly alcohol-free fountain concentrate formula 2:

[0061]

[0062]

[0063] Dilute the environment-friendly alcohol-free dampening solution in water at a volume ratio of 3:97, and the physical properties of the obtained environmental-friendly alcohol-free dampening solution are as follows: pH=4.19, electrical conductivity=1199 μS / cm, dynamic surface tension= 32.2dynes / cm, viscosity = 1.78cps, the emulsification rate of the environment-friendly alcohol-free fountain solution of high-grade offset printing ink: 35.9% for yellow ink, 41.1% for red ink, 41.8% for blue ink, and 41.6% for black ink. This environmentally friendly alcohol-free fountain solution has been used on press for two weeks with no problems.

Embodiment 3

[0065] Environment-friendly alcohol-free fountain concentrate formula 3:

[0066]

[0067] Dilute the environment-friendly alcohol-free dampening solution in water at a volume ratio of 3:97, and the physical properties of the obtained environment-friendly alcohol-free dampening solution are as follows: pH=4.22, electrical conductivity=1216 μS / cm, dynamic surface tension= 31.9dynes / cm, viscosity=1.81cps, the emulsification rate of the environment-friendly alcohol-free dampening solution of high-grade offset printing ink is: 36.1% for yellow ink, 41% for red ink, 41.9% for blue ink, and 42.1% for black ink. This environmentally friendly alcohol-free fountain solution has been used on press for two weeks with no problems.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Dynamic surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com