Preparation method of ultraviolet resistant and aging resistant antenna outer cover

An anti-ultraviolet and anti-aging technology, used in household components, applications, coatings, etc., can solve the problems of high manufacturing cost, poor, unable to meet the requirements of all-weather applications, and achieve the effect of high strength and reduced processing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

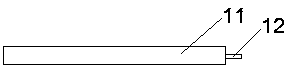

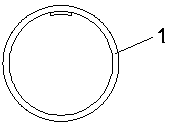

[0026] Such as figure 1 and 2 As shown, take the processing of cylindrical antenna cover as an example.

[0027] A preparation method for an anti-ultraviolet and anti-aging antenna cover, comprising the following steps:

[0028] (1) Making a mould: making a mold according to the shape of the antenna cover 1, the mold includes a sub-mould;

[0029] (2) Blister molding: place the basic sheet and the sub-molds in the blister machine for blister molding, cut after the blister machine 4 is processed, and obtain a subdivision 11 of the antenna cover after cutting. A little edge 12 is left on both sides of the subdivision; the obtained subdivision 11 is a tiled rectangle, which can be wound into a cylindrical shape;

[0030] (3) Bonding: coating the edge 12 of the subsection 11 with dichloromethane, and connecting the subsections 11 together through dichloromethane to obtain the final antenna cover 1;

[0031] (4) Surface treatment: soak the bonded antenna cover 1 in the surface ...

Embodiment 2

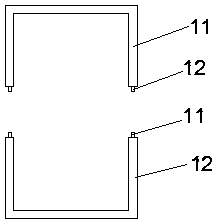

[0035] Such as image 3 and 4 As shown, take the processing of square cylindrical antenna cover as an example.

[0036] A preparation method for an anti-ultraviolet and anti-aging antenna cover, comprising the following steps:

[0037] (1) Make a mold: make a mold according to the shape of the antenna cover 1, the mold includes two sub-moulds, and the shapes of the sub-moulds are combined to form the mold;

[0038] (2) Blister molding: place the base sheet and the sub-molds in the blister machine for blister molding, cut after the blister machine 4 is processed, and obtain two antenna cover divisions 11 after cutting. A little edge 12 is left on both sides of the subsection 11; the obtained two subsections 11 can be combined to form a square tube shape;

[0039] (3) Bonding: Coating the edges 12 of the subsections 11 with an adhesive, and connecting the subsections together through the adhesive to obtain the final antenna cover;

[0040] (4) Surface treatment: Soak the bon...

Embodiment 3

[0044] A preparation method for an anti-ultraviolet and anti-aging antenna cover, comprising the following steps:

[0045] (1) Making a mold: making a mold according to the shape of the antenna cover, the mold includes at least one sub-mould, and the shapes of the sub-moulds are combined to form the mold;

[0046] (2) Blister molding: put the base sheet and sub-molds in a blister machine for blister molding, and then cut them after the blister machine is finished. After cutting, at least one antenna cover section is obtained. A little margin is left on both sides of the division;

[0047] (3) Bonding: Coating the edges of the subsections with dichloromethane, and connecting the subsections together with dichloromethane to obtain the final antenna cover;

[0048] (4) Surface treatment: Soak the bonded antenna cover in the surface protection solution and take it out.

[0049] The base sheet includes the following raw materials in parts by weight: PVC resin, silicone oil, glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com