Anti-loose high-temperature alloy lock washer and manufacturing method thereof

A technology for stop washers and high-temperature alloys, applied in the direction of washers, manufacturing tools, metal processing equipment, etc., can solve the problems of lack of bending process, insufficient number of locking claws, and inability to meet the requirements of preventing nut rotation, so as to ensure flight quality, The effect of reducing the drop-off failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

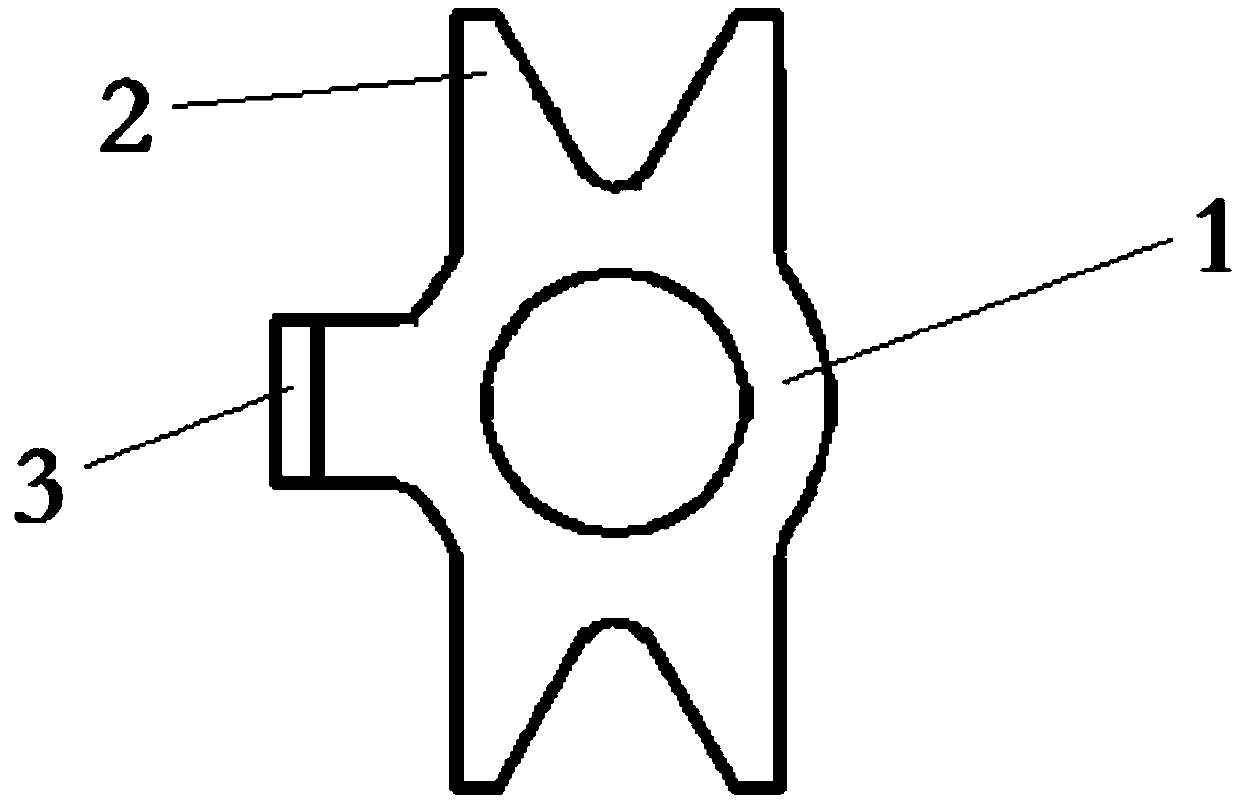

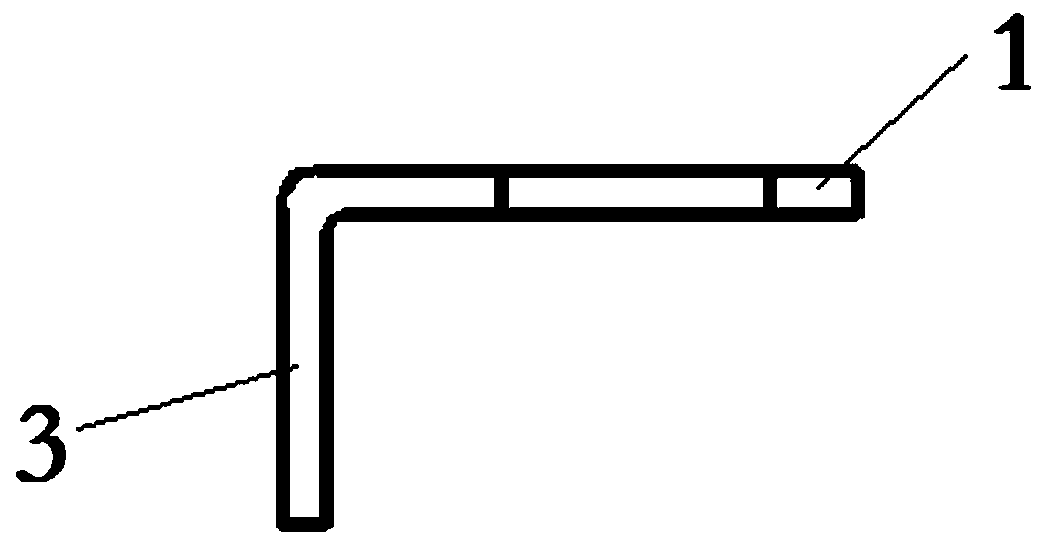

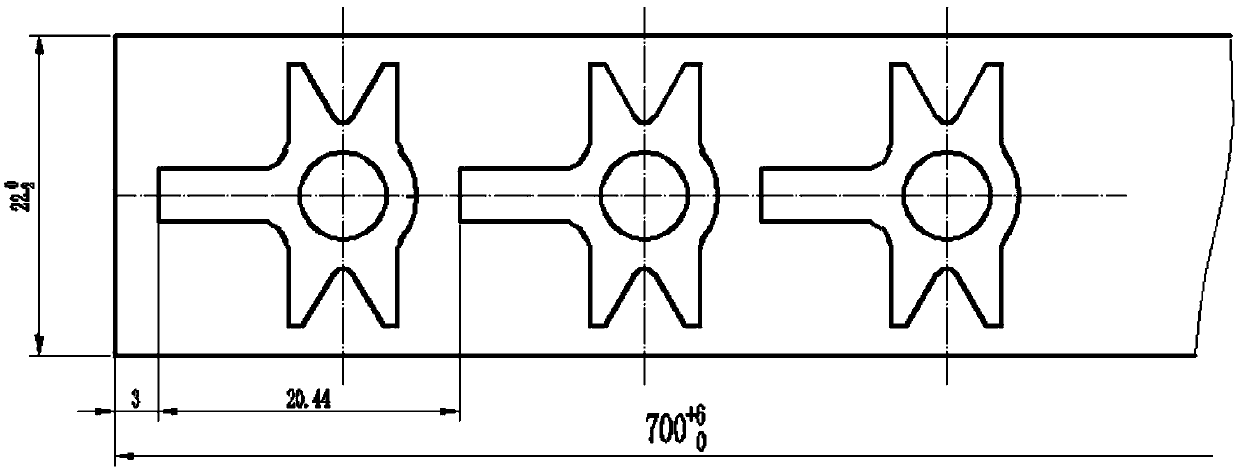

[0043] Such as Figure 1 to Figure 10 As shown, the present invention provides an anti-loose superalloy stop washer, which includes a ring part 1, two locking claws 2 are respectively arranged on the left and right sides of the ring part 1, and four locking claws are arranged on the left and right sides 2. The bottom of the ring part 1 is provided with a stop claw 3, the length of the stop claw 3 is 8mm, the overall thickness of the stop washer is 1mm, and it is made of GH3044 material.

[0044] According to the feedback of the failure information of a certain type of aero-engine heat shield nut falling off, the failure analysis is carried out, and the nut locking torque is calculated by using the knowledge of mechanics. At the same time, the simulation software such as Ansys is used to simulate the stress of the stop washer to guide the stop washer The material, size and structure of the engine were changed, combined with the temperature measurement test and hardness test of ...

Embodiment 2

[0081] An anti-loose superalloy stop washer and a manufacturing method thereof, other features are the same as in embodiment 1, the difference is that another method for deburring by rolling is disclosed in this embodiment, specifically as follows: in step 4 Abrasives are glass balls, the specifications of which are SΦ3mm-SΦ5mm spheres, the volume ratio of abrasives to parts is 3:1-4:1, and the grinding time is 25min-30min.

[0082] The same technical effect as that of Embodiment 1 can be achieved by adopting the above-mentioned method for deburring by rolling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com