Preparation method of nitrogen doped biomass porous carbon and oxygen reduction catalyzing application of nitrogen doped biomass porous carbon

A technology of porous carbon and nitrogen doping, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low stability, limitation, deactivation, etc., and achieve excellent electrocatalytic performance , good cycle life and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

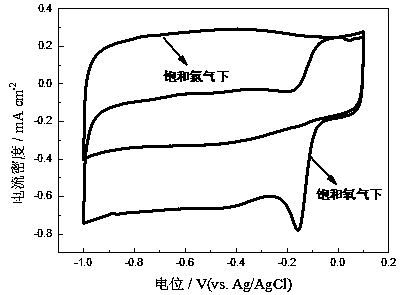

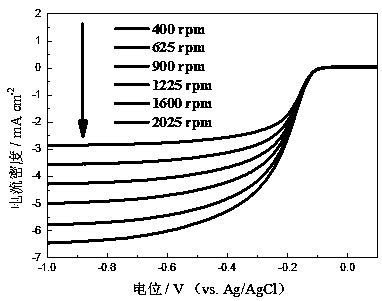

[0031] After cleaning and drying the collected discarded cantaloupe peels, the temperature was raised to 400°C at a heating rate of 5°C / min in a nitrogen atmosphere, and then carbonized at 400°C for 2 hours to obtain biochar; the biochar was mixed with melamine, Potassium bicarbonate was put into a planetary ball mill at a mass ratio of 1 : 3 : 3, processed at a speed of 300 rpm for 30 min, and forward and reverse 15 min each; in a nitrogen atmosphere, the temperature was raised to 800 °C at a rate of 2 °C / min. ℃ for synergistic doping-activation to obtain un-acid-washed nitrogen-doped biomass porous carbon; the obtained un-acid-washed nitrogen-doped cantaloupe porous carbon was placed in a magnetic stirrer with 1 mol L -1 hydrochloric acid at 400 rpm and 50°C for 2 h, then washed with water until neutral, dried at 80°C and ground into fine particles for storage. The product is nitrogen-doped biomass porous carbon.

Embodiment 2

[0033]After cleaning and drying the collected discarded cantaloupe peels, the temperature was raised to 400°C at a heating rate of 5°C / min in a nitrogen atmosphere, and then carbonized at 400°C for 2 hours to obtain biochar; the biochar was mixed with melamine, Potassium bicarbonate was put into a planetary ball mill at a mass ratio of 1:3:3, and processed at a speed of 300 rpm for 30 minutes, with forward and reverse rotations each for 15 minutes; in a nitrogen atmosphere, the temperature was raised to 900 °C at a rate of 2 °C / min. ℃ for synergistic doping-activation to obtain un-acid-washed nitrogen-doped biomass porous carbon; the obtained un-acid-washed nitrogen-doped cantaloupe porous carbon was placed in a magnetic stirrer with 1 mol L -1 hydrochloric acid at 400 rpm and 50°C for 2 h, then washed with water until neutral, dried at 80°C and ground into fine particles for storage. The product is nitrogen-doped biomass porous carbon.

Embodiment 3

[0035] After cleaning and drying the collected discarded cantaloupe peels, the temperature was raised to 400°C at a heating rate of 5°C / min in a nitrogen atmosphere, and then carbonized at 400°C for 2 hours to obtain biochar; the biochar was mixed with melamine, Potassium bicarbonate was put into a planetary ball mill at a mass ratio of 1:1:3, and processed at a speed of 300 rpm for 30 minutes, with forward and reverse rotations each for 15 minutes; in a nitrogen atmosphere, the temperature was raised to 800 °C at a rate of 2 °C / min. ℃ for synergistic doping-activation to obtain un-acid-washed nitrogen-doped biomass porous carbon; the obtained un-acid-washed nitrogen-doped cantaloupe porous carbon was placed in a magnetic stirrer with 1 mol L -1 hydrochloric acid at 400 rpm and 50°C for 2 h, then washed with water until neutral, dried at 80°C and ground into fine particles for storage. The product is nitrogen-doped biomass porous carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com