Preparation, product and application of fluorescently labeled polyester/periodic mesoporous bone filling composites with degradable rate

A fluorescent labeling and degradation rate technology, which is applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems that the degradation rate and bone healing rate cannot be directly observed, the mechanical properties do not match natural bone, and the degradation time is uncontrollable. , to achieve the effects of increasing dispersion uniformity and organic-inorganic interfacial compatibility, overcoming molecular weight loss, and improving luminous efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a polyester / periodic mesoporous bone-filling composite material whose degradation rate can be fluorescently marked. The biodegradable polylactic acid-based random copolymer is used as the matrix, and the modified rare earth periodic mesoporous fluorescent material is used as the matrix. An enhancer and a fluorescent agent are used to prepare a composite material with self-enhancement effect and degradation rate that can be fluorescently marked, including the following steps:

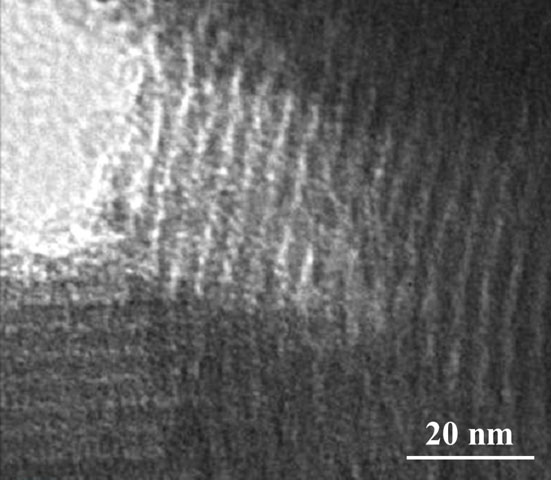

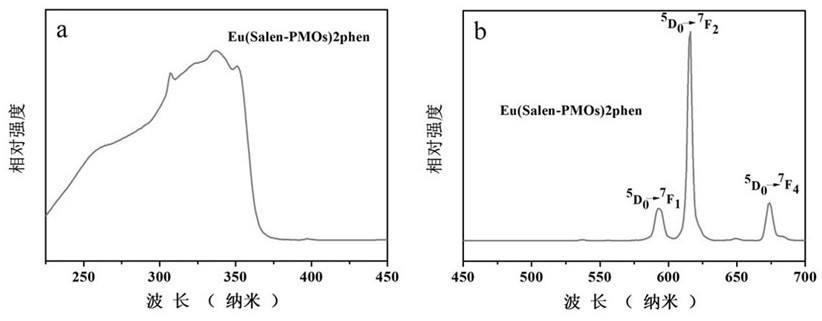

[0040] 1) Preparation of rare earth periodic mesoporous nanoparticles with fluorescent properties:

[0041] First, carry out amination modification on the rare earth complex: add 20 mL tetrahydrofuran solvent into a three-necked flask, then add 2 mmol 0.5366 g N,N'-bis(salicylidene)ethylenediamine (Salen), and wait until it is completely dissolved Finally, 4 mmol1.0 g triethoxysilyl isopropyl isocyanate (TEPIC) was added, condensed and refluxed for 12 h under the protection ...

Embodiment 2

[0051] Approximate with embodiment 1 step, comprise the following steps:

[0052] 1) Preparation of rare earth periodic mesoporous nanoparticles with fluorescent properties:

[0053]First, carry out amination modification on the rare earth complex: add 20 mL tetrahydrofuran solvent into a three-necked flask, then add 2 mmol 0.5366 g N,N'-bis(salicylidene)ethylenediamine (Salen), and wait until it is completely dissolved Finally, 4 mmol1.0 g triethoxysilyl isopropyl isocyanate (TEPIC) was added, condensed and refluxed for 12 h under the protection of nitrogen at 65 °C, and finally the obtained solution was separated and purified by a rotary evaporator to obtain a light yellow viscous The viscous liquid is denoted as Salen-Si; followed by in situ synthesis of periodic mesoporous graft complex composites: the template agent cetyltrimethylammonium bromide (CTAB) (0.416 g) and NaOH (0.1888 g) were dissolved In deionized water (12.72 mL), a mixed solution of Salen-Si and 1,2-bis(tr...

Embodiment 3

[0061] Approximate with embodiment 1 step, comprise the following steps:

[0062] 1) Preparation of rare earth periodic mesoporous nanoparticles with fluorescent properties:

[0063] First, carry out amination modification on the rare earth complex: add 20 ml tetrahydrofuran solvent into a three-necked flask, then add 2 mmol 0.5366 g N,N'-bis(salicylidene)ethylenediamine (Salen), and wait until it is completely dissolved Finally, 4 mmol1.0 g triethoxysilyl isopropyl isocyanate (TEPIC) was added, condensed and refluxed for 12 h under the protection of nitrogen at 65 °C, and finally the obtained solution was separated and purified by a rotary evaporator to obtain a light yellow viscous The viscous liquid is denoted as Salen-Si; followed by in situ synthesis of periodic mesoporous graft complex composites: the template agent cetyltrimethylammonium bromide (CTAB) (0.416 g) and NaOH (0.1888 g) were dissolved In deionized water (12.72 mL), then a mixed solution of Salen-Si and 1,2-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com