Graphene-based gas sensitive sensor material loaded with metal palladium and preparation and application thereof

A gas-sensing sensing material, graphene-based technology, applied in the field of graphene-based gas-sensing sensing materials and its preparation and application, can solve the problems affecting the sensor's working stability, affecting the accuracy, direct work, etc., to achieve excellent hydrogen Sensing performance, good catalytic reactivity, and enhanced adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The present embodiment provides the preparation of a metal palladium-supported graphene-based gas-sensing sensing material, comprising the following steps:

[0066] 1) Warm up 10mL of concentrated sulfuric acid (98%) to 90°C, slowly add 2g of K 2 S 2 o 8 , after stirring evenly, slowly add 2g P 2 o 5 Stir evenly, adjust the temperature to 80°C, add 1.8g graphene, and maintain the temperature for 30 minutes; dry at 60°C for 4-6 hours, then add deionized water, filter and wash until the filtrate is neutral, and dry at room temperature , to obtain pre-oxidized graphene;

[0067] 2) Slowly add the pre-oxidized graphene obtained in step 1) into 92mL of concentrated sulfuric acid (98%), slowly add 12g of KMnO at a temperature not higher than 10°C 4 , adjust the temperature to 35°C, and react for 2h;

[0068] 3) Dilute the reaction mixture in step 2) with 184 mL of deionized water, adjust the temperature to 60°C after dilution, and react for 2 hours;

[0069] Wherein, t...

Embodiment 2

[0078] This embodiment provides a kind of preparation of metal palladium-supported graphene-based gas-sensing sensing material, and the difference from Example 1 is only: the difference in reaction time in step 6);

[0079] Specifically, "Then add the reducing agent solution, and react at a temperature of 90°C for 6 hours to form a black suspension;"

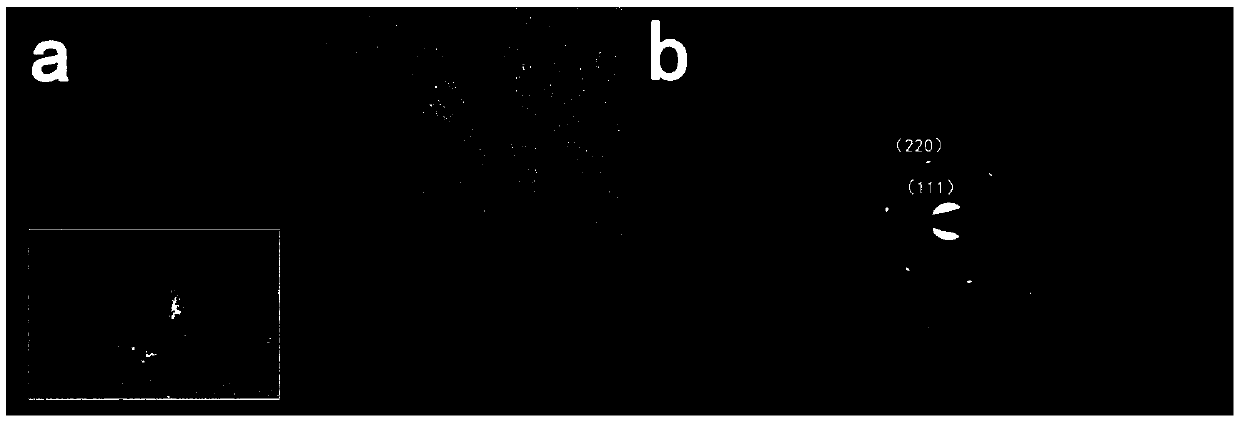

[0080] Such as image 3 It is the SAED diagram of the Pd / rGO composite material prepared in this example.

Embodiment 3

[0082] This embodiment provides the preparation of a metal palladium-supported graphene-based gas-sensing sensing material. The difference from Example 1 is that the "surfactant" in step 6) is replaced by "CTAB" by PVP (polyvinylpyrrolidone). (cetyltrimethylammonium bromide)";

[0083] Specifically, "Prepare palladium chloride at a concentration of 0.5mol / L to prepare 2 mL of a dispersion, and mix it with the dispersion of graphene oxide described in step 5); stir for 30 minutes, then add CTAB (hexadecyltrimethyl ammonium bromide) according to the concentration of 1mg / mL, the 5mL dispersion liquid was prepared and continued to stir for 30min; then the reducing agent solution was added and reacted for 4h at a temperature of 90°C to form a black suspension”

[0084] Such as Figure 5It is the SEM image of the metal palladium supported graphene-based gas sensing material (Pd / rGO composite material) prepared in this embodiment. Among them, due to the addition of the surfactant C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com