Radiation-resistant fabric preparation process

A production process and anti-radiation technology, which is applied in the field of production process of anti-radiation fabrics, can solve the problems of single function of fabrics and inability to meet the needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

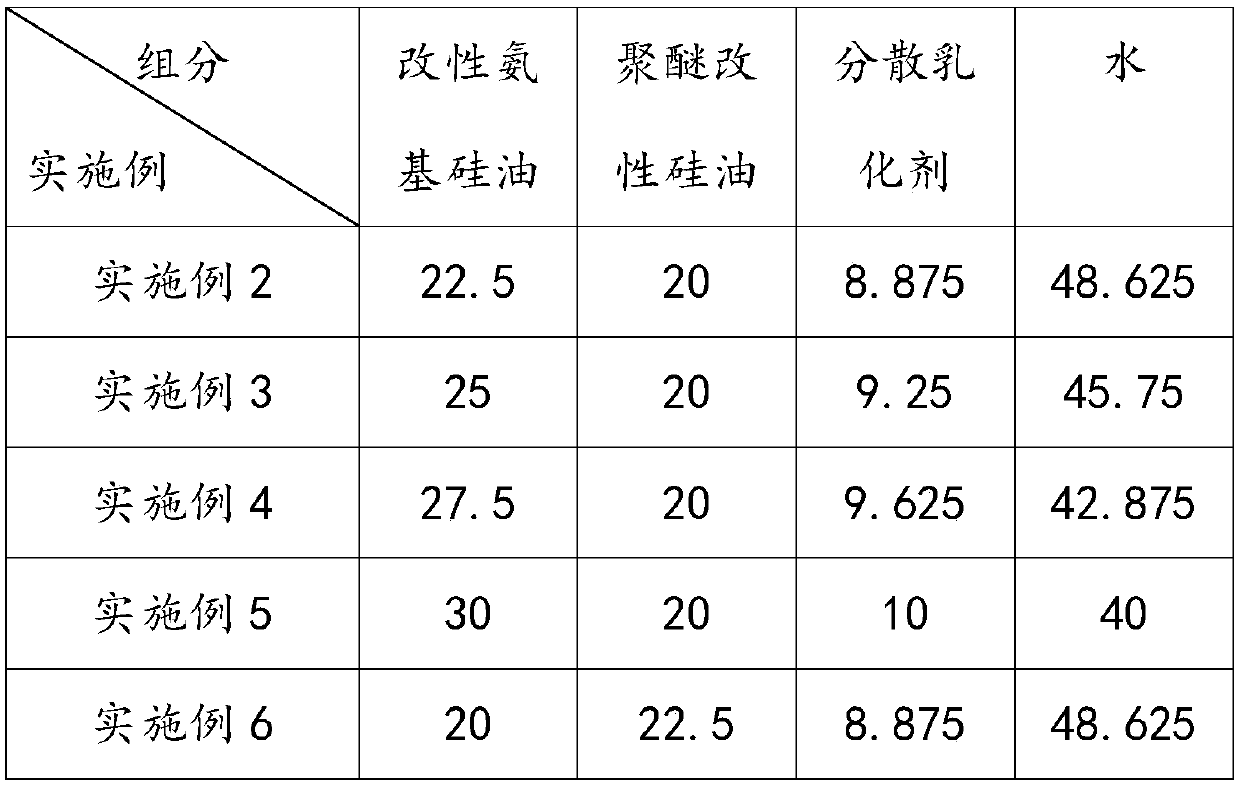

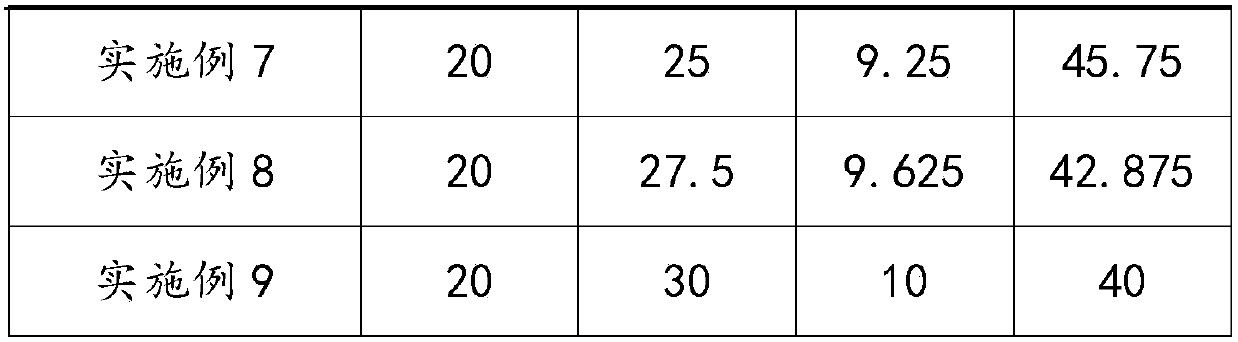

[0030] Pre-treatment of polyester and flax fiber: (1) Configure softener: Mix 20% of modified amino silicone oil, 20% of polyether modified silicone oil, 10% of dispersing emulsifier and 50% of water at a temperature of 85°C;

[0031] (2) Enzyme treatment solution is configured: 8 parts of cellulase, 8 parts of phosphate anionic surfactant, 60 parts of polyethylene glycol type nonionic surfactant and 5 parts of dilute sodium hydroxide pH regulator are mixed evenly, And adjust the temperature of the mixed solution to 30°C;

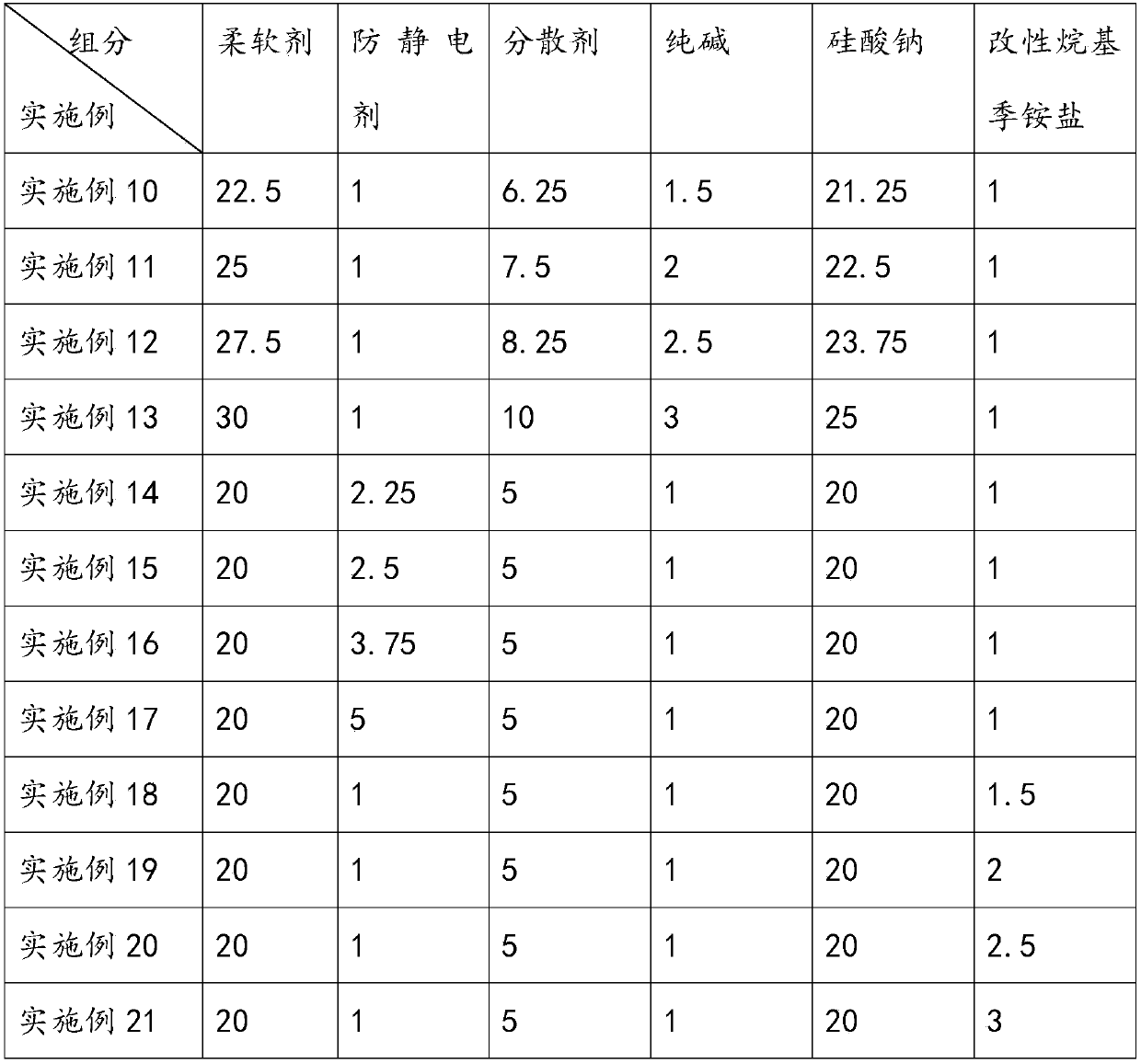

[0032] (3) Configure the second auxiliary agent: mix 20 parts of softening agent, 1 part of antistatic agent, 5 parts of dispersant, 1 part of soda ash, 20 parts of sodium silicate, and 1 part of modified alkyl quaternary ammonium salt;

[0033] (4) Enzyme treatment of polyester and flax fibers: first put the polyester and flax fibers into the enzyme treatment solution, keep the temperature constant, and perform enzyme treatment for 30 minutes, then remove ...

Embodiment 30

[0049]The difference from embodiment 30 to embodiment and embodiment 33 is: the composition of enzyme treatment liquid is as follows in parts by weight:

[0050]

[0051] The difference between Example 34 to Example 37 and Example 1 is that the temperature of the enzyme treatment solution is as follows: unit °C

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com