A room-temperature-cured superhydrophobic coating for electric power and its preparation and use methods

A super-hydrophobic coating, room temperature curing technology, applied in anti-fouling/underwater coatings, anti-corrosion coatings, coatings, etc., can solve the problem of reducing the insulation performance of insulating equipment and the anti-corrosion performance of power facilities, and the WCA value cannot meet the efficient removal of inorganic pollution Insulators and insulators flashover and other problems, to achieve the effect of controllable film thickness, good recoatability, and good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the superhydrophobic nano-SiO through alkyl modification 2 The preparation method is as follows:

[0040] Use hexadimethylsilane to treat ordinary nano-SiO 2 Modified by hexadimethylsilazane (HMDS) on SiO 2 A hydrolysis reaction occurs on the surface, and the siloxane group (-O-Si(CH 3 ) 3 ) to replace the surface hydroxyl group (-OH), the specific preparation process is: first nano-SiO 2 placed in N 2 In the atmosphere, pre-activate at 390°C to 400°C for 60 minutes, then pass in HMDS liquid at 70-75°C, after 50 minutes of reaction, use N 2 Purge the reaction product to obtain superhydrophobic nano-SiO with a WCA of 162°-165° 2 Powder.

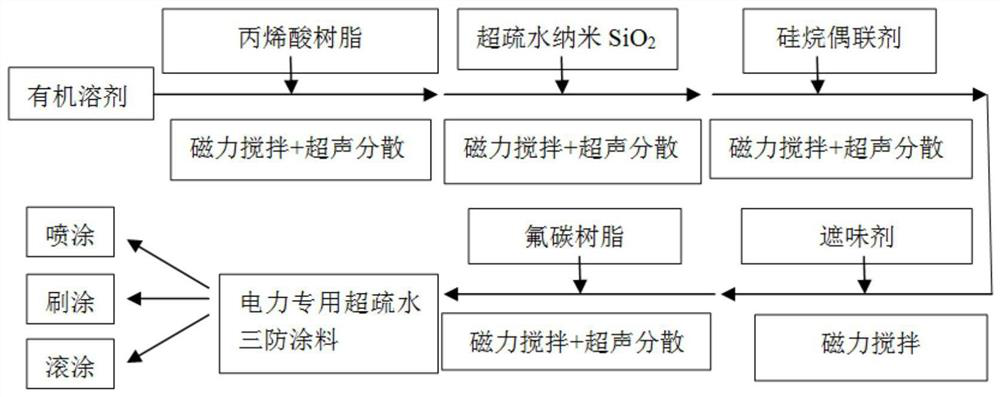

[0041] The preparation method of special superhydrophobic coating for electric power in the present embodiment (such as figure 1 ) specifically includes the following steps, wherein the allocation ratio of each group is shown in Table 1 below:

[0042] Table 1: The distribution ratio of each component of the...

Embodiment 2

[0068] In this embodiment, the superhydrophobic nano-SiO through alkyl modification 2 The preparation method is as follows:

[0069] Use hexadimethylsilane to treat ordinary nano-SiO 2 Modified by hexadimethylsilazane (HMDS) on SiO 2 A hydrolysis reaction occurs on the surface, and the siloxane group (-O-Si(CH 3 ) 3 ) to replace the surface hydroxyl group (-OH), the specific preparation process is: first nano-SiO 2 placed in N 2 In the atmosphere, pre-activate at 350°C to 360°C for 55 minutes, then pass in HMDS liquid at 60°C to 70°C, after 45 minutes of reaction, use N 2 Purge the reaction product to obtain superhydrophobic nano-SiO with a WCA of 160°-163° 2 Powder.

[0070] The preparation method of special superhydrophobic coating for electric power in the present embodiment (such as figure 1 ) specifically includes the following steps, wherein the allocation ratio of each group is shown in Table 4 below:

[0071] Table 4: The distribution ratio of each component o...

Embodiment 3

[0084] In this embodiment, the superhydrophobic nano-SiO through alkyl modification 2 The preparation method is as follows:

[0085] Use hexadimethylsilane to treat ordinary nano-SiO 2 Modified by hexadimethylsilazane (HMDS) on SiO 2 A hydrolysis reaction occurs on the surface, and the siloxane group (-O-Si(CH 3 ) 3 ) to replace the surface hydroxyl group (-OH), the specific preparation process is: first nano-SiO 2 placed in N 2 In the atmosphere, pre-activate at 300°C to 310°C for 30 minutes, and then pass in HMDS liquid at 50°C to 55°C. After 30 minutes of reaction, use N 2 Purge the reaction product to obtain superhydrophobic nano-SiO with a WCA of 160°-163° 2 Powder.

[0086] The preparation method of special superhydrophobic coating for electric power in the present embodiment (such as figure 1 ) specifically includes the following steps, wherein the allocation ratio of each group is shown in Table 5 below:

[0087] Table 5: The distribution ratio of each compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com