Graphene-based silicon carbon composite material and preparation method thereof

A silicon-carbon composite material and composite material technology, applied in the field of lithium-ion batteries, can solve the problems of negative electrode volume expansion and poor cycle performance, and achieve the effects of buffering volume expansion, high specific capacity, and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

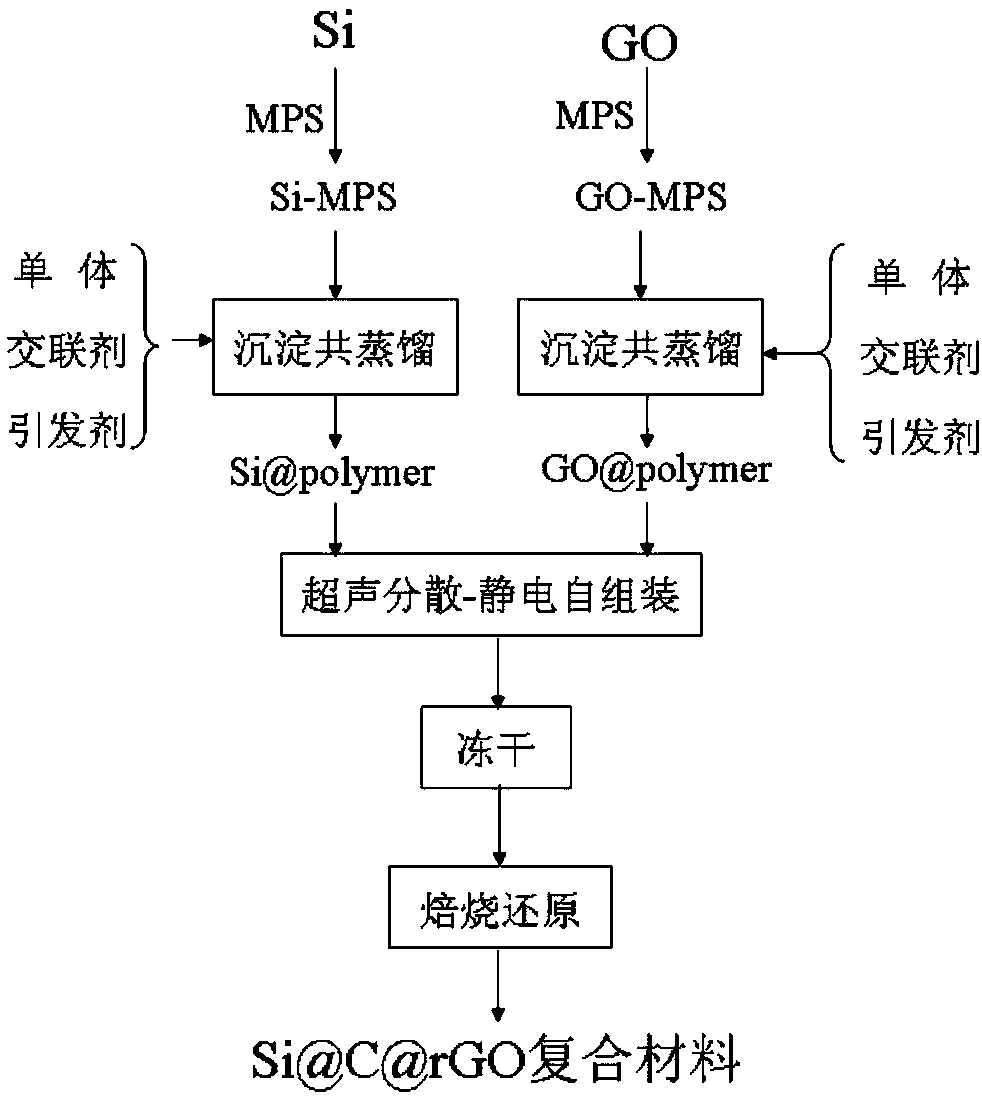

[0075] See figure 1 , The method for preparing the aforementioned silicon-based composite negative electrode material includes the following steps:

[0076] 1) Using precipitation co-distillation method to coat the surface of graphene oxide and nano silicon particles with oppositely charged organic polymer layers:

[0077] a) Ultrasonic dispersion of graphene oxide into ethanol to obtain a mixed solution; according to the ratio of graphene oxide to MPS mass ratio of 1:(1~5), MPS is added to the mixed solution, heated, stirred, centrifuged / re-dispersed 1. Wash and purify to obtain MPS modified GO, namely GO-MPS;

[0078] b) The GO-MPS obtained in step a) was ultrasonically dispersed into acetonitrile, and then the ratio of GO-MPS, monomer, crosslinking agent and initiator was 1g: (1~2)mL: (0.5~2)mL: (0.015~0.12) g of monomer, crosslinking agent and initiator are added separately, and the temperature is controlled to reflux to obtain GO@polymer composite material with an organic polym...

Embodiment 1

[0095] (1) See figure 1 , 0.5g of graphene oxide (GO) was added to 250mL of absolute ethanol, and dispersed by ultrasound, after adding 1.0g of methacryloxypropyltrimethoxysilane (MPS), at 50℃ Stir for 48h. After centrifugation / re-dispersion, washing and purification three times, GO modified with MPS was obtained, labeled GO-MPS.

[0096] The obtained 0.5 g of GO-MPS was ultrasonically dispersed in 100 mL of acetonitrile, 0.75 mL of Vim, 0.75 mL of ethylene glycol dimethacrylate (EGDMA) were added, and 0.05 g of azobisisobutyronitrile (AIBN) was added to The initiator was refluxed at 100°C for 1.5 hours to obtain GO@PVim composite microspheres with positive charges on the surface.

[0097] (2) Disperse 0.5 g of silicon balls with a diameter of about 50 nm into 95 mL of absolute ethanol, add 5 mL of 25% ammonia water under stirring, and then slowly add 7.5 g of MPS to the above silicon suspension, stir for 20 hours, and use alcohol Wash it three times with water to obtain Si-MPS p...

Embodiment 2

[0107] (1) 0.25 g of GO was added to 250 mL of ethanol and dispersed by ultrasound, after adding 0.25 g of MPS, stirring was carried out at 30° C. for 24 h. After centrifugation / re-dispersion, washing and purification three times, GO modified with MPS was obtained, labeled GO-MPS.

[0108] The obtained 0.25g of GO-MPS was ultrasonically dispersed in 143mL of acetonitrile, 0.25mL of VPA, 0.125mL of EGDMA, and 0.00375g of AIBN were added respectively, and refluxed at 90℃ for 1.0h to obtain a negatively charged composite GO@ PVPA.

[0109] (2) Disperse 0.5 g of silicon balls with a diameter of about 50 nm into 475 mL of anhydrous ethanol solution, add 25 mL of 25% ammonia water under stirring, and then slowly add 5.0 g of MPS to the above silicon suspension, and stir for 12 hours. Washed with alcohol and water three times each to obtain Si-MPS particles grafted with active double bonds on the surface.

[0110] The obtained 0.5g Si-MPS particles were ultrasonically dispersed in 290mL a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com