Hollow glass microsphere surface modification method, low density and high weather resistant polypropylene composite material and preparation method thereof

A technology of hollow glass microspheres and surface modification, which is applied in the field of low-density high weather-resistant polypropylene composite materials and their preparation, and the surface modification of hollow glass microspheres, which can solve the problem of broken microspheres and low interfacial force of glass microspheres , uneven mixing and other problems, to achieve the effect of strengthening compatibility, solving the decline of light stability, and avoiding poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

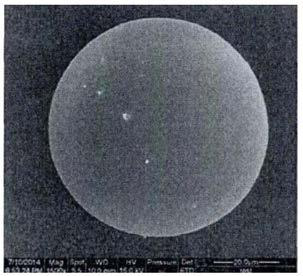

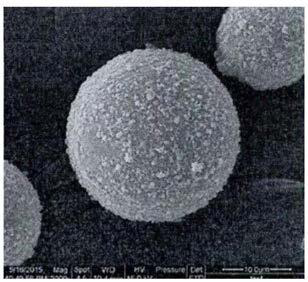

[0060] Prepare surface-modified hollow glass microspheres, the steps are as follows:

[0061] 1) Preparation of modified polymer solution

[0062] a) Weigh each raw material according to the following weight percentage: 48.54% of alkyl methacrylate (40 parts of cyclohexyl methacrylate, 10 parts of lauryl methacrylate), 4.85 parts of long-chain silane coupling agent with double bond % (5 parts of methacryloxypropyltriethoxysilane), 9.71% of 4-methacryloxybenzophenone (10 parts of 4-methacryloxybenzophenone), Initiator 3.88% (4 parts of azobisisobutyronitrile), chain transfer agent 3.88% (α-methylstyrene dimer 4 parts), organic solvent 29.13% (30 parts of ethanol);

[0063] b) Add 30 parts by mass (parts by mass, the same below) of ethanol to the reactor and raise the temperature to 80°C, add 40 parts of cyclohexyl methacrylate, 10 parts of lauryl methacrylate, 10 parts of 4-methacryloyloxy Base benzophenone, 4 parts of azobisisobutyronitrile, and 4 parts of α-methylstyrene di...

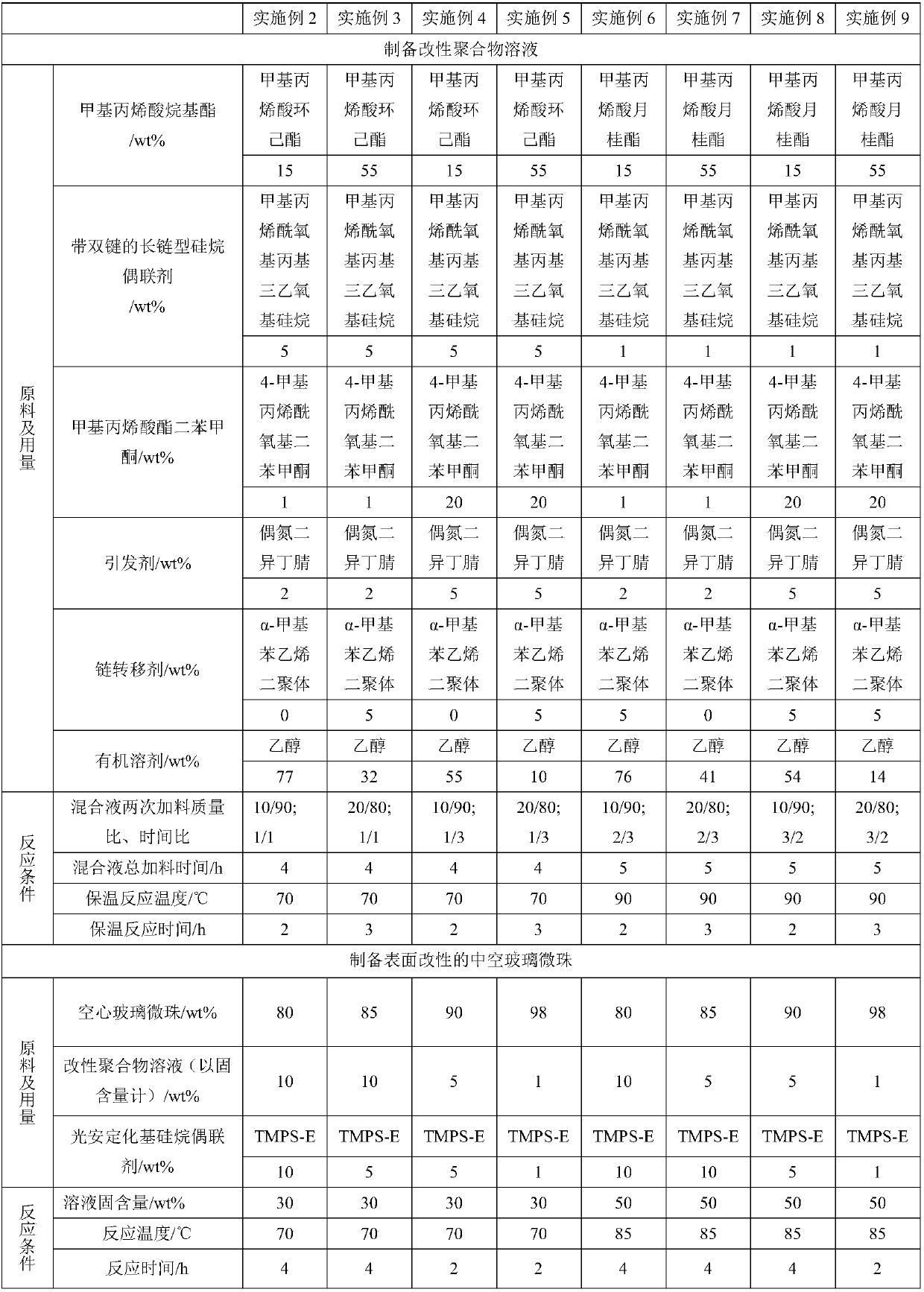

Embodiment 2-9

[0069] Prepare surface-modified hollow glass microspheres, the preparation method is the same as in Example 1, and the specific conditions are as follows in Table 1:

[0070] Table 1 embodiment 2-9 raw material ratio and reaction conditions

[0071]

Embodiment 10

[0073] The raw material is composed of: 48-98% of polypropylene, 0.2-1% of heat stabilizer, 0.2-1% of lubricant, 0-20% of toughening agent, 1-15% of talcum powder, and surface-modified hollow glass microspheres ( Example 1 preparation) 1-15%.

[0074] 69 parts (parts by mass, the same below) polypropylene, 0.2 part tetrakis [β-(3', 5'-di-tert-butyl-4'-hydroxyphenyl) propionate] pentaerythritol ester (primary antioxidant), 0.2 Parts of three (2,4-di-tert-butyl) phosphite (secondary antioxidant), 0.6 parts of magnesium stearate (lubricant), 10 parts of POE (ethylene, octene copolymer), 10 parts of talc, 10 parts of surface-modified hollow glass microspheres (prepared in Example 1).

[0075] Preparation method: Weigh the above-mentioned raw materials in proportion, put them into a high-speed mixer and mix them for 3-10 minutes, then place the mixed raw materials in a place with an aspect ratio of 48:1, a screw speed of 200r / min, and a temperature of 195-215°C. It is melted and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com