Technology and device for synthesizing dimethyl carbonate

A technology of dimethyl carbonate and synthesis process, which is applied in the preparation of carbonate/haloformate, carbon monoxide and oxygen, preparation of organic compounds, etc. The problem of high energy consumption in liquid mixing and discharging can achieve the effect of reducing energy consumption, high yield and increasing content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

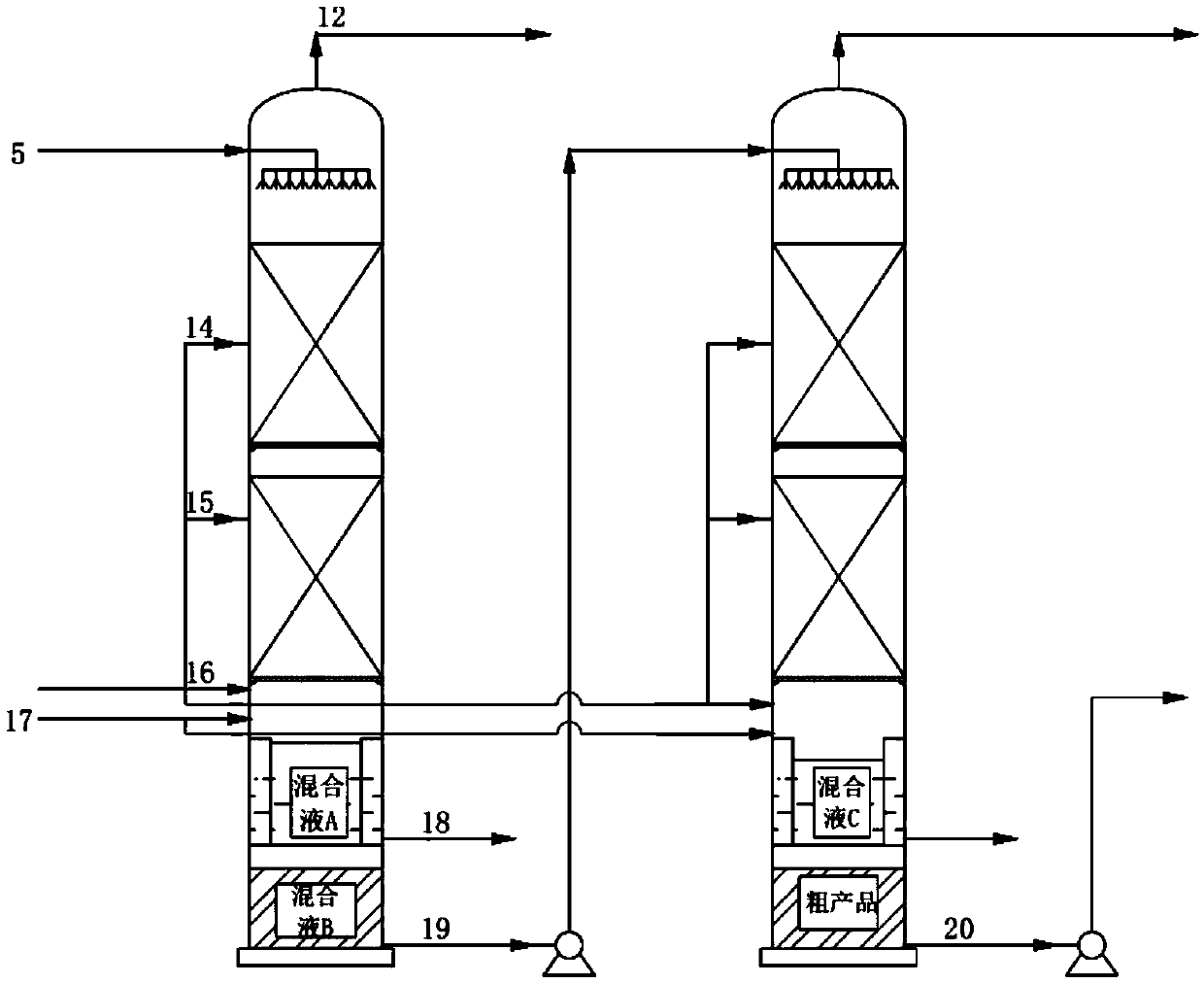

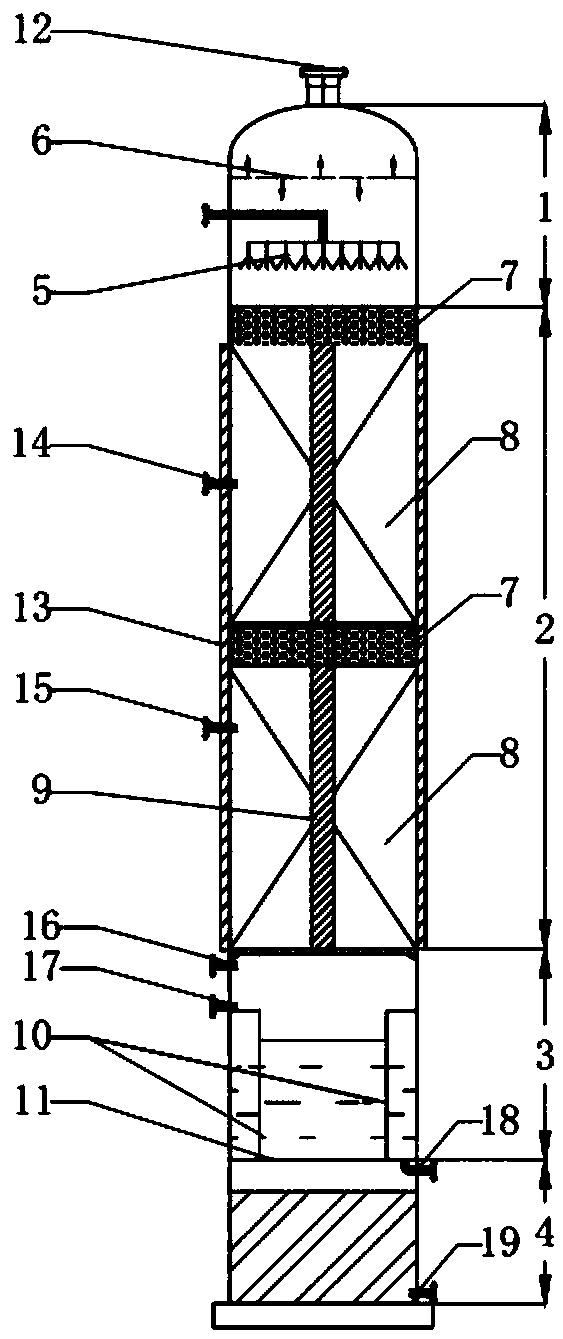

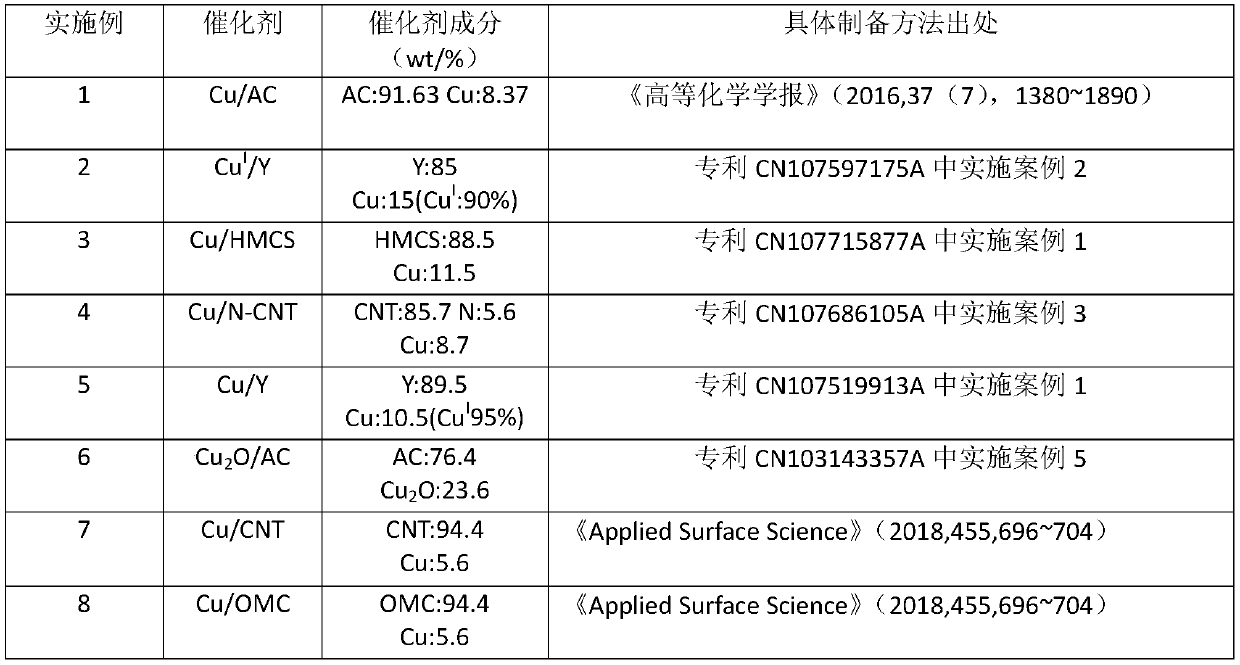

[0030] The height of the upper section 1 of the I and No. II reactors of the present invention is 300 millimeters, the height of the middle section 2 is 1200 millimeters, the height of the lower section 3 is 400 millimeters, and the height of the tower kettle 4 is 300 millimeters, and the same diameter of four parts is 80 millimeters. The inlet distributor 5 is located in the middle of the upper section 1, and the outlet distributor 6 is located at 1 / 2 between the inlet distributor 5 and the top of the upper section 1. The opening ratio of the outlet distributor 6 is 15%, and the aperture is 1.5mm. The reaction section of the middle section 2 is divided into upper and lower sections, and the ceramic ball bed (7) is positioned between the two sections and the top of the upper section of the reaction section, and 1600g of Cu / AC catalysts are packed in the catalyst bed 8 in a bulk stacking mode. First add 800g of catalyst to fill up the lower part of the reaction section, then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com