Flexible seamless expansion joint connecting material and preparation method thereof

A seamless expansion and joint material technology, applied in the field of road building materials and engineering, can solve the problems of debonding and water seepage of the original bridge deck pavement, irritating odor operators, and rough material consumption ratio, so as to solve the problem of water damage. Problems and jumping of expansion joints, good economy, effect of solving uneven material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

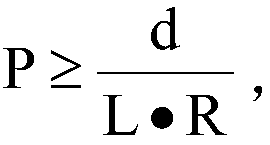

[0043] This embodiment provides a flexible seamless expansion joint joint compound. The raw materials for the preparation of the flexible seamless expansion joint material include the following raw material components: high elastic sealant, aggregate and filler.

[0044] The mass percentage of the high elastic sealant is 17%-24%, the mass percentage of the aggregate is 75%-85%, and the mass percentage of the filler is 0%-8%.

[0045] The above-mentioned flexible seamless expansion joint material is a kind of high-viscosity, flexible, stretchable, compressible recovery, and can resist traffic load damage, which is formed by mixing high-elastic sealant, aggregate and filler evenly. The bridge expansion joint joint material, the flexible seamless expansion joint joint material can adapt to the expansion and contraction of the bridge for adaptive deformation.

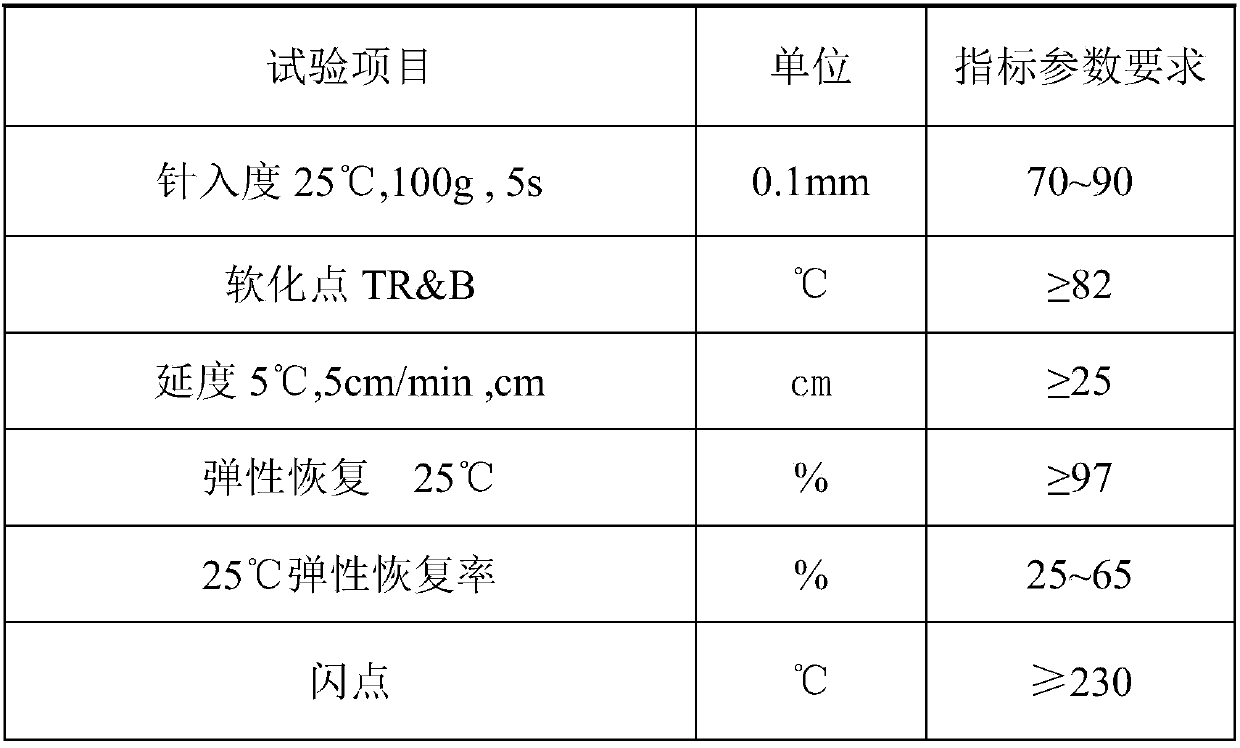

[0046] In a specific example, the high-elastic sealant is a polymer-modified asphalt obtained by modifying a non-rubber ...

Embodiment 2

[0069] This embodiment provides a method for preparing a flexible seamless expansion joint compound, which includes the following steps:

[0070] The various components of the flexible seamless expansion joint joint material are weighed, including 20% by mass of high-elastic sealant, 75% by mass of aggregate, and 5% by mass of filler.

[0071] The mixer used in the production of asphalt mixture is used to produce flexible seamless expansion joint joint material.

[0072] The aggregate is heated to a first preset temperature, and the aggregate and filler are uniformly mixed to form a mixture; the first preset temperature is 190°C-220°C.

[0073] Heat the high elastic sealant to a second preset temperature; the second preset temperature is 170°C-180°C.

[0074] Add part or all of the heated high elastic sealant into the heated mixture, mix evenly and maintain the third preset temperature to form a flexible seamless expansion joint joint material, the third preset temperature ...

Embodiment 3

[0083] This embodiment provides a method for using the above-mentioned flexible seamless expansion joint compound, which includes the following steps:

[0084] Heat the aggregate to 200°C, use the existing asphalt mixer to pre-mix the aggregate with the filler for 5-10 seconds, and mix evenly to form a mixture.

[0085] Heat the high elastic sealant to 170°C.

[0086] Mix the heated mixture with 70% of the total amount of the heated high elastic sealant, and mix it with an asphalt mixer for 90-120 seconds; stir evenly and keep it at 190°C to form a flexible seamless expansion joint joint material to ensure that the ore Adhesive properties of materials and high elastic sealants. The wet mixing time when the mixture is mixed with the heated high elastic sealant is not less than 90s. The flexible seamless expansion joint joint compound formed by mixing can be used for the joint at the position of the expansion joint of the road construction road surface.

[0087] The ex-factor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com