A kind of discoloration agent and discoloration method of wood chemical discoloration induced by copper ion

A chemical discoloration and discoloration agent technology, applied in the field of wood manufacturing, can solve the problems of distorted wood color, reducing the clarity of wood texture, and too consistent color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

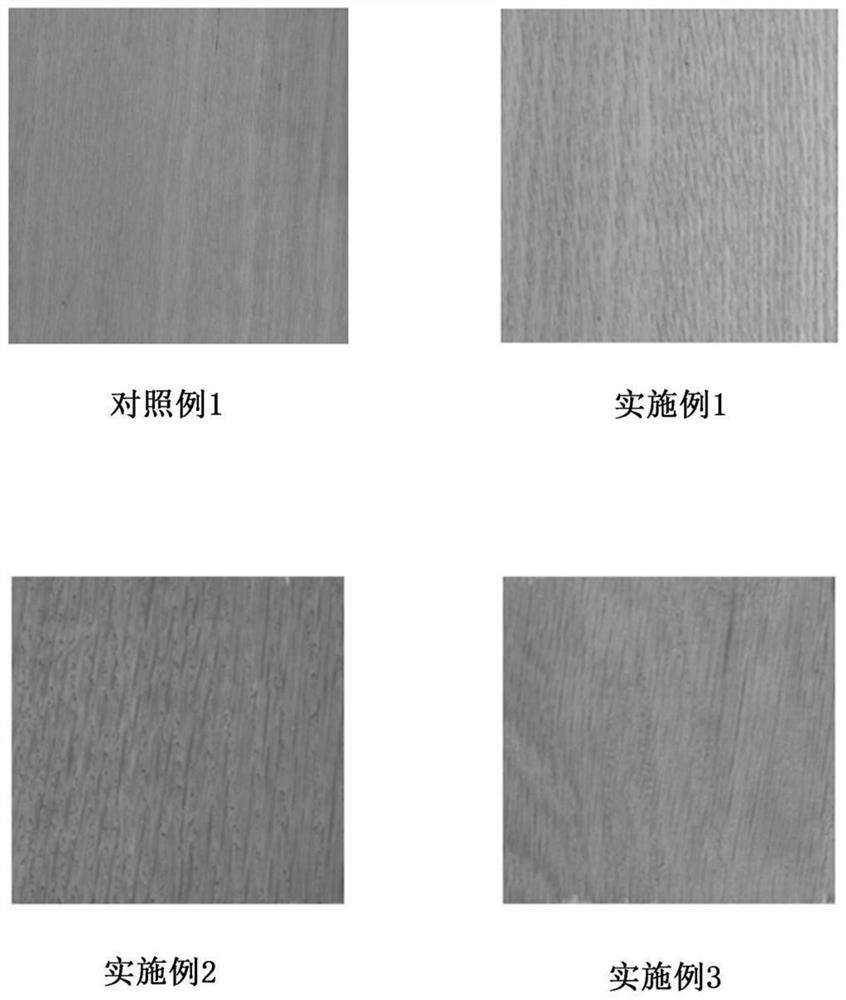

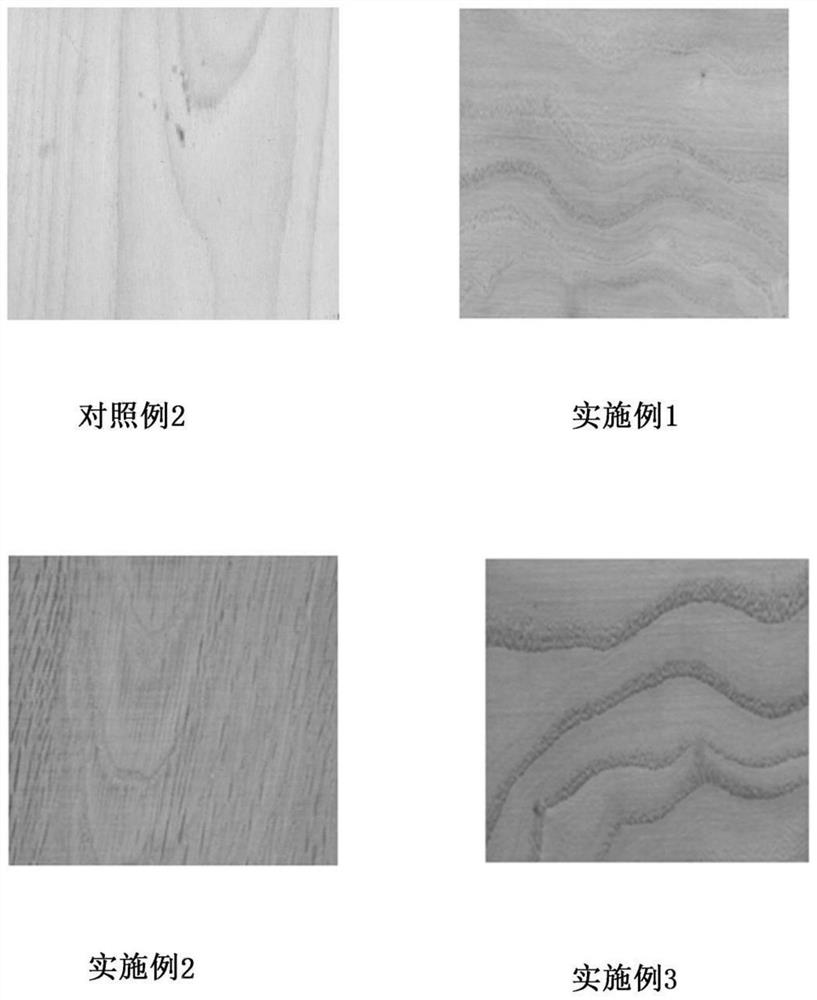

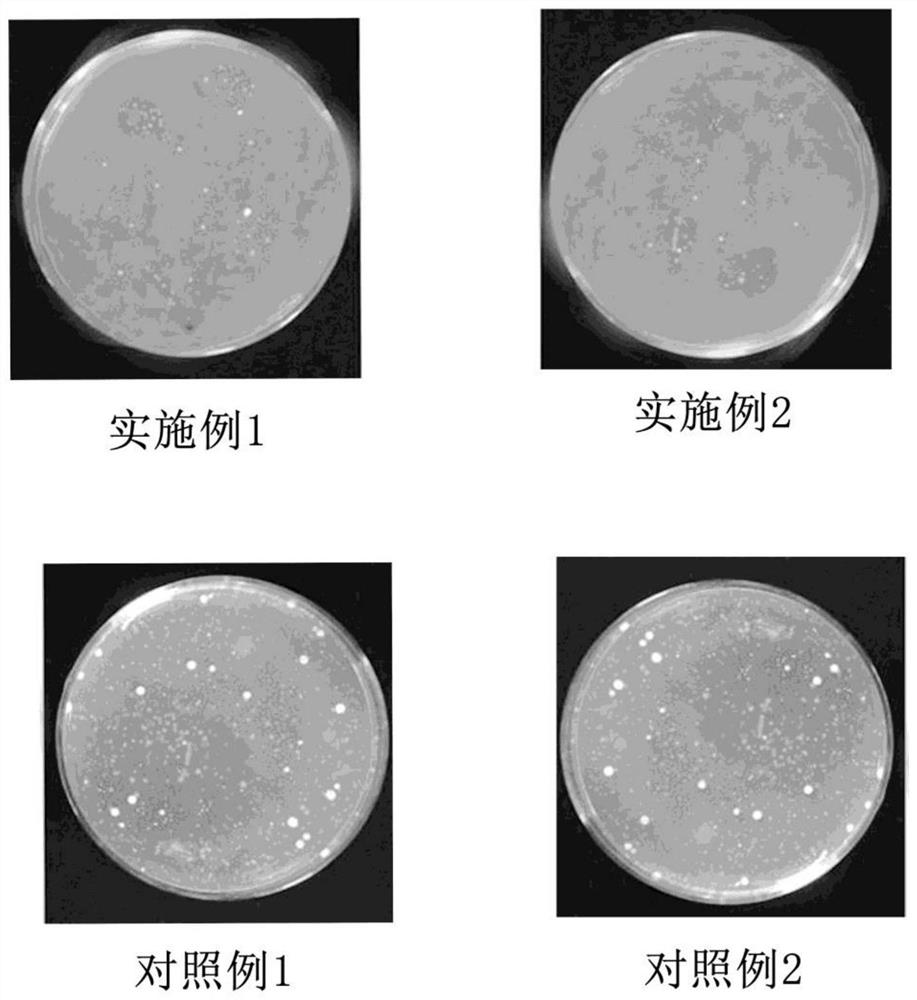

Embodiment 1

[0036] Embodiment 1: a kind of discoloration agent and discoloration method thereof of wood chemical discoloration induced by copper ion:

[0037] Make the wood chemical discoloration agent with the raw materials of following weight ratio, mix and stir evenly and make discoloration agent;

[0038] Copper chloride 10g, cetylpyridinium bromide 1g,

[0039] Sodium alkylsulfonate 10g, water 800g.

[0040] Utilize above-mentioned wood chemical discoloration agent to carry out wood chemical discoloration to the wood veneer of white oak material, and carry out according to the following steps:

[0041] 1. The wood veneer is dried until the water content in the wood veneer is 9%;

[0042] 2. Apply the discoloration agent evenly on the wood veneer by wiping, and the coating amount is 30g / m 2 After uniform coating, put it in a vacuum drying oven for 25 seconds at 55°C to complete the wood discoloration.

Embodiment 2

[0043] Embodiment 2: a kind of discoloration agent and discoloration method thereof of copper ion-induced wood chemical discoloration:

[0044] Make the wood chemical discoloration agent with the raw materials of following weight ratio, mix and stir evenly and make discoloration agent;

[0045] Cupric chloride 20g, cetylpyridinium chloride 1g,

[0046] Phenyl salicylate 1g, Alkylphenol polyoxyethylene ether 60g,

[0047] Water 910g.

[0048] Utilize above-mentioned wood chemical discoloration agent to carry out wood chemical discoloration to the wood veneer of white oak material, and carry out according to the following steps:

[0049] 1. Drying the wood veneer until the water content in the wood veneer is 10%;

[0050] 2. Apply the discoloration agent evenly on the wood veneer by wiping, and the coating amount is 35g / m 2 ,After uniform coating, place it in a vacuum drying oven at 60°C for 30 seconds to complete the wood discoloration.

Embodiment 3

[0051] Embodiment 3: a kind of discoloration agent and discoloration method thereof of copper ion induced wood chemical discoloration:

[0052] Make the wood chemical discoloration agent with the raw materials of following weight ratio, mix and stir evenly and make discoloration agent;

[0053] Cupric chloride 50g, cetylpyridinium chloride 2.5g,

[0054] Phenyl salicylate 2.5g, sodium lauryl sulfate 100g,

[0055] 900g of water.

[0056] Utilize above-mentioned wood chemical discoloration agent to carry out wood chemical discoloration to the wood veneer of white oak material, and carry out according to the following steps:

[0057] 1. Place the wood veneer for drying treatment until the water content in the wood veneer is 10%;

[0058] 2. Apply the discoloration agent evenly on the wood veneer by wiping, and the coating amount is 35g / m 2 ,After uniform coating, place it in a vacuum drying oven for quick drying at 65°C for 35 seconds to complete the wood discoloration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com