Non-solvent-type sports field skid-resistant layer texture self-formation material and preparation method thereof

A technology for sports venues and anti-slip layers, which is applied to roads, pavements, buildings, etc., can solve the problems affecting the environmental sanitation, appearance and normal use of sports venues, affecting the normal performance of athletes, and high energy consumption in the production process, so as to reduce injuries to athletes , beautiful color, and the effect of reducing consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

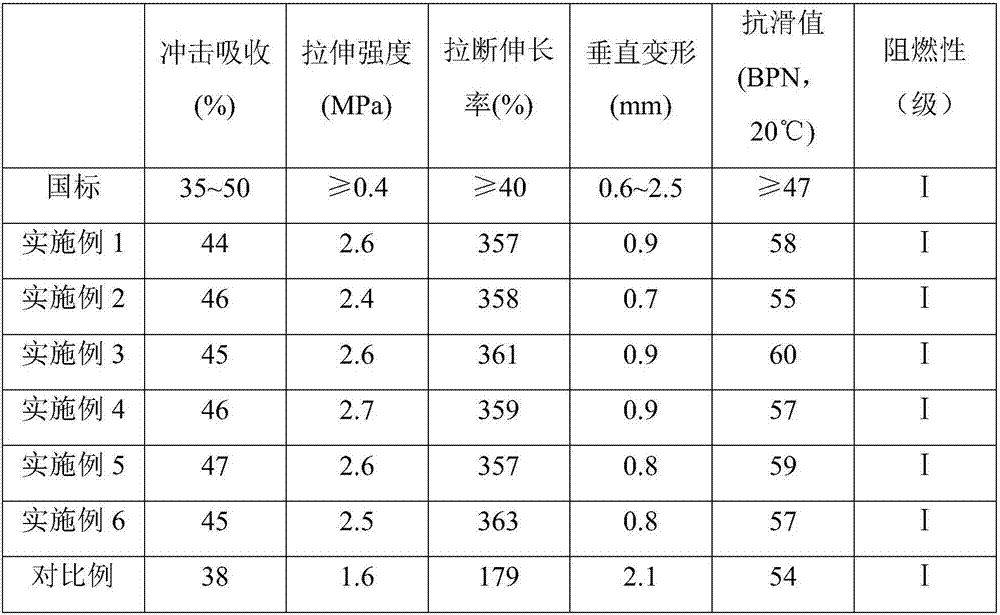

Examples

Embodiment 1

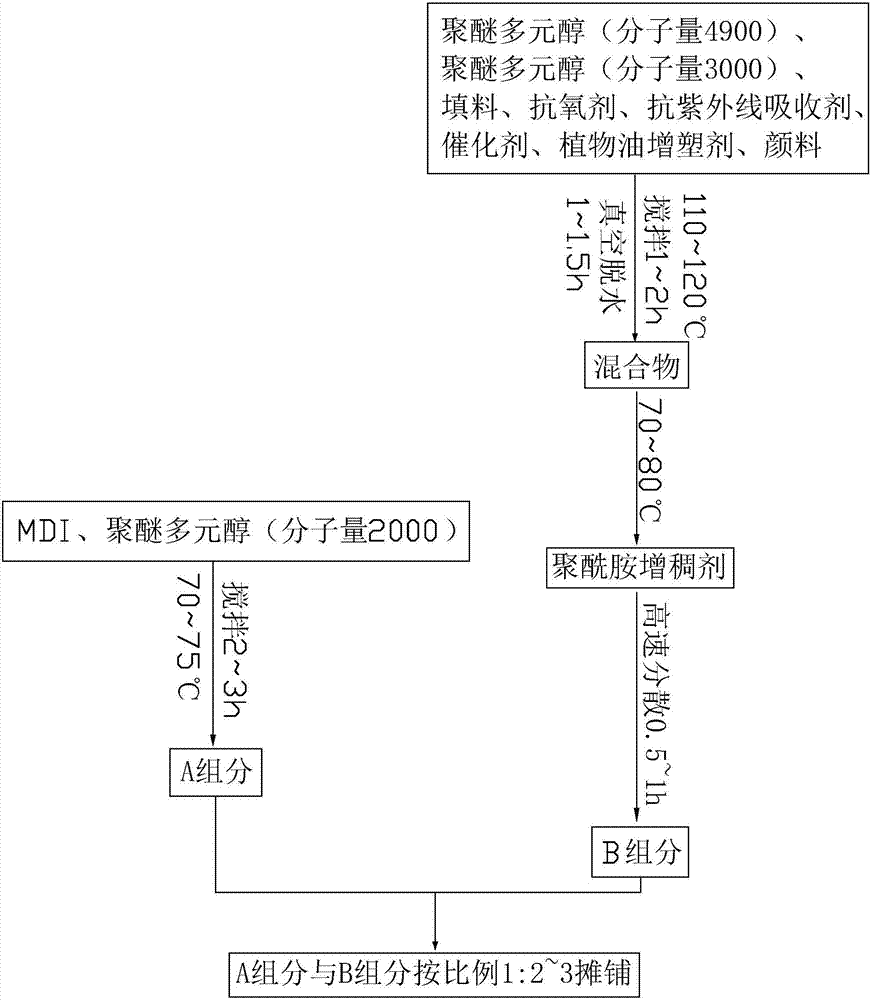

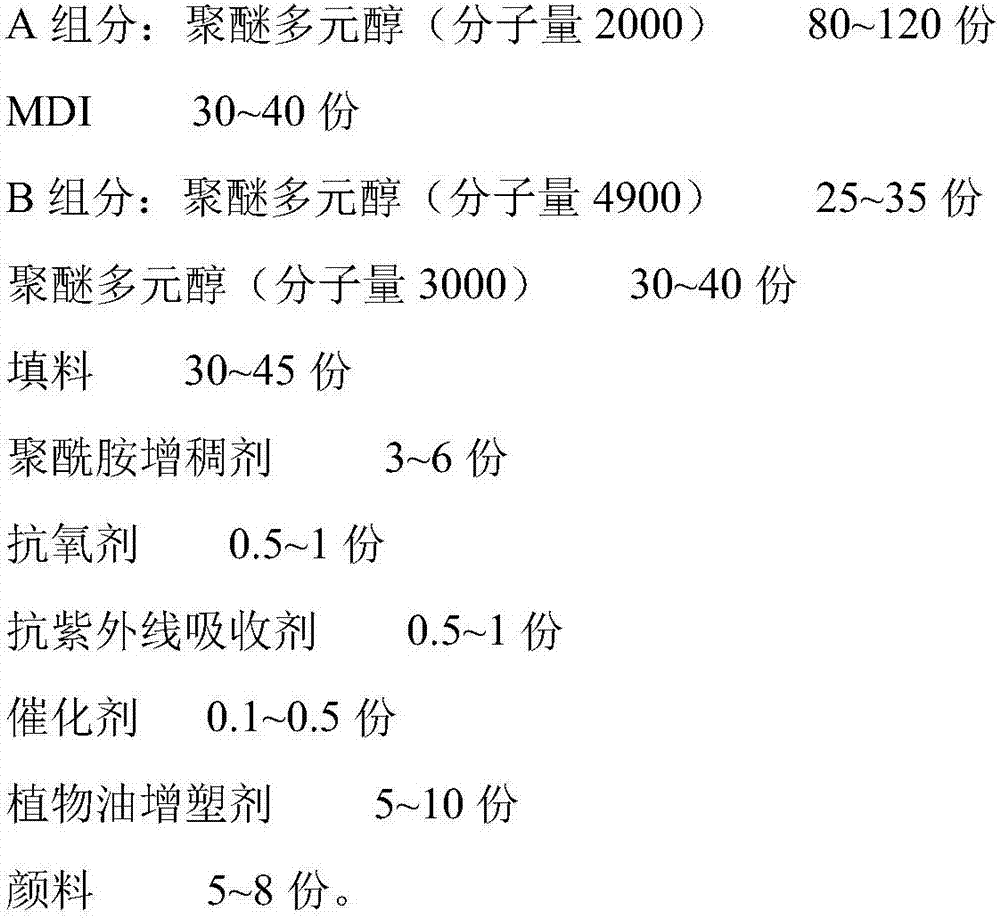

[0045] like figure 1 As shown, a preparation method of a solvent-free anti-skid layer self-knotting material for sports venues is prepared according to the following mass ratio:

[0046] A component:

[0047] Polytetrahydrofuran ether glycol (molecular weight 2000) 80kg

[0048] MDI 30kg

[0049] Add the measured amount of component A into the reactor, raise the temperature to 75°C, and stir for 2 hours to obtain component A.

[0050] B component:

[0051] Polyoxypropylene diol (molecular weight 4900) 25kg

[0052] Polyoxypropylene triol (molecular weight 3000) 30kg

[0053] 400 mesh talcum powder 30kg

[0054]Polyamide thickener 3kg

[0055] Antioxidant 264 0.5kg

[0056] Anti-ultraviolet absorber UV-81 0.5kg

[0057] Rare earth naphthenate 0.1kg

[0058] Bismuth isooctanoate catalyst 0.1kg

[0059] Chlorinated palm oil methyl ester 10kg

[0060] Iron oxide red 5kg.

[0061] Add the metered component B except polyurethane thickener to the reactor, raise the tempe...

Embodiment 2

[0064] A component:

[0065] Polytetrahydrofuran ether glycol (molecular weight 2000) 90kg

[0066] MDI 32kg

[0067] B component:

[0068] Polyoxypropylene diol (molecular weight 4900) 27kg

[0069] Polyoxypropylene triol (molecular weight 3000) 32kg

[0070] 400 mesh talcum powder 33kg

[0071] Polyamide thickener 4kg

[0072] Antioxidant 264 0.6kg

[0073] Anti-ultraviolet absorber UV-81 0.6kg

[0074] Rare earth naphthenate 0.2kg

[0075] Bismuth isooctanoate catalyst 0.1kg

[0076] Chlorinated palm oil methyl ester 10kg

[0077] Iron oxide red 6kg.

Embodiment 3

[0079] A component:

[0080] Polytetrahydrofuran ether glycol (molecular weight 2000) 100kg

[0081] MDI 34kg

[0082] B component:

[0083] Polyoxypropylene diol (molecular weight 4900) 29kg

[0084] Polyoxypropylene triol (molecular weight 3000) 34kg

[0085] 400 mesh talcum powder 36kg

[0086] Polyamide thickener 5kg

[0087] Antioxidant 264 0.7kg

[0088] Anti-ultraviolet absorber UV-81 0.7kg

[0089] Rare earth naphthenate 0.1kg

[0090] Bismuth isooctanoate catalyst 0.2kg

[0091] Chlorinated palm oil methyl ester 11kg

[0092] Iron oxide red 6kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com