Bearing outer surface grinding and conveying and machining all-in-one machine

An external surface, all-in-one technology, applied in the grinding frame, the machine tool designed for grinding the rotating surface of the workpiece, the grinding workpiece support, etc. output and other issues, to achieve the effect of mass production, good use effect, and avoiding omissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

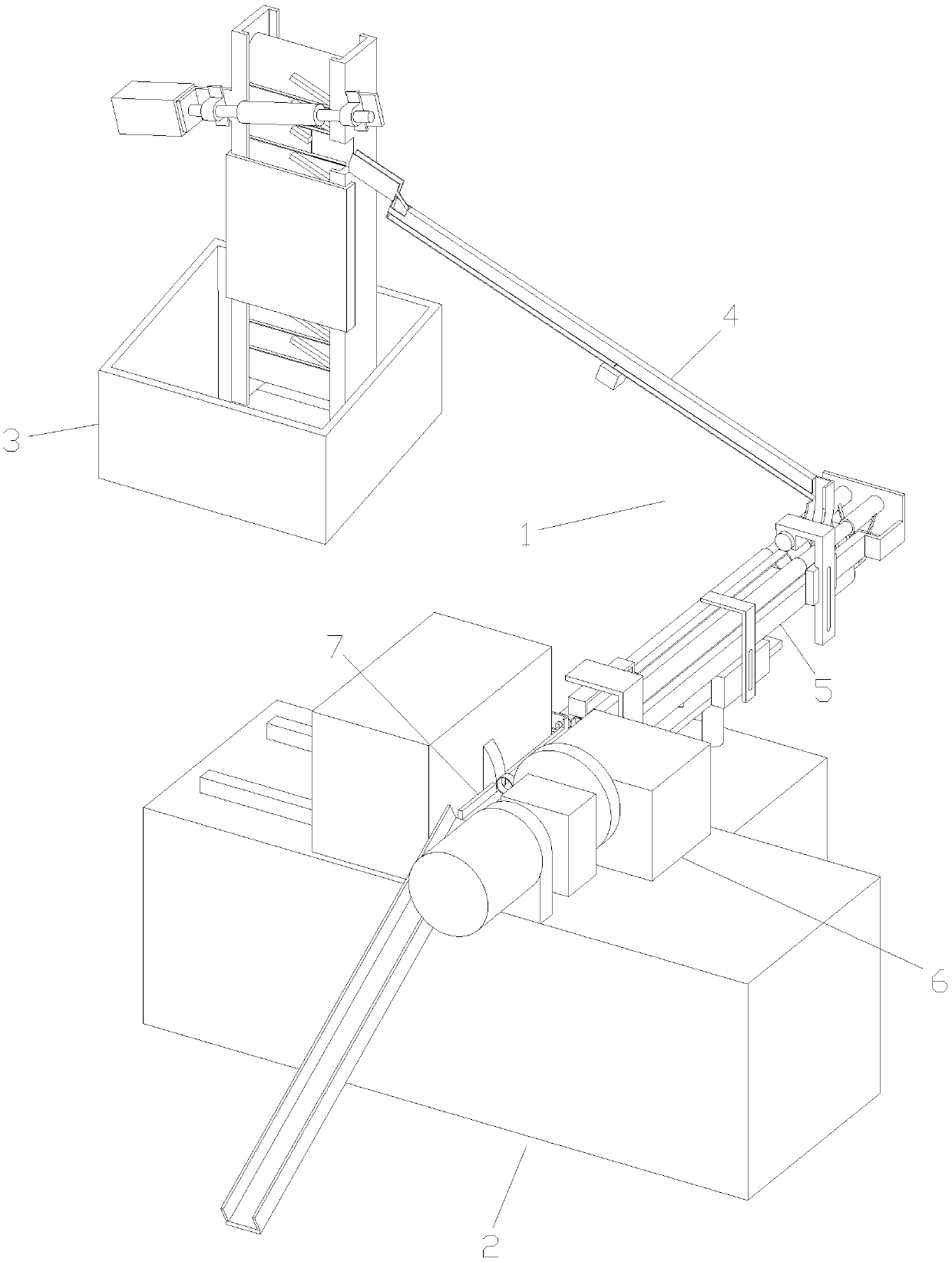

[0033] Referring to the accompanying drawings: this bearing outer surface grinding, conveying and processing integrated machine includes a conveying device 1 and a grinding device 2. The conveying device 1 includes a vertical conveying unit 3, and a feeding device installed at the discharge end of the vertical conveying unit 3. Track 4, the material pushing unit 5 that is connected with the discharge end of feeding track 4 to realize feeding, grinding device 2 includes processing unit 6 and is placed in processing unit 6 and is used in cooperation with pushing unit 5;

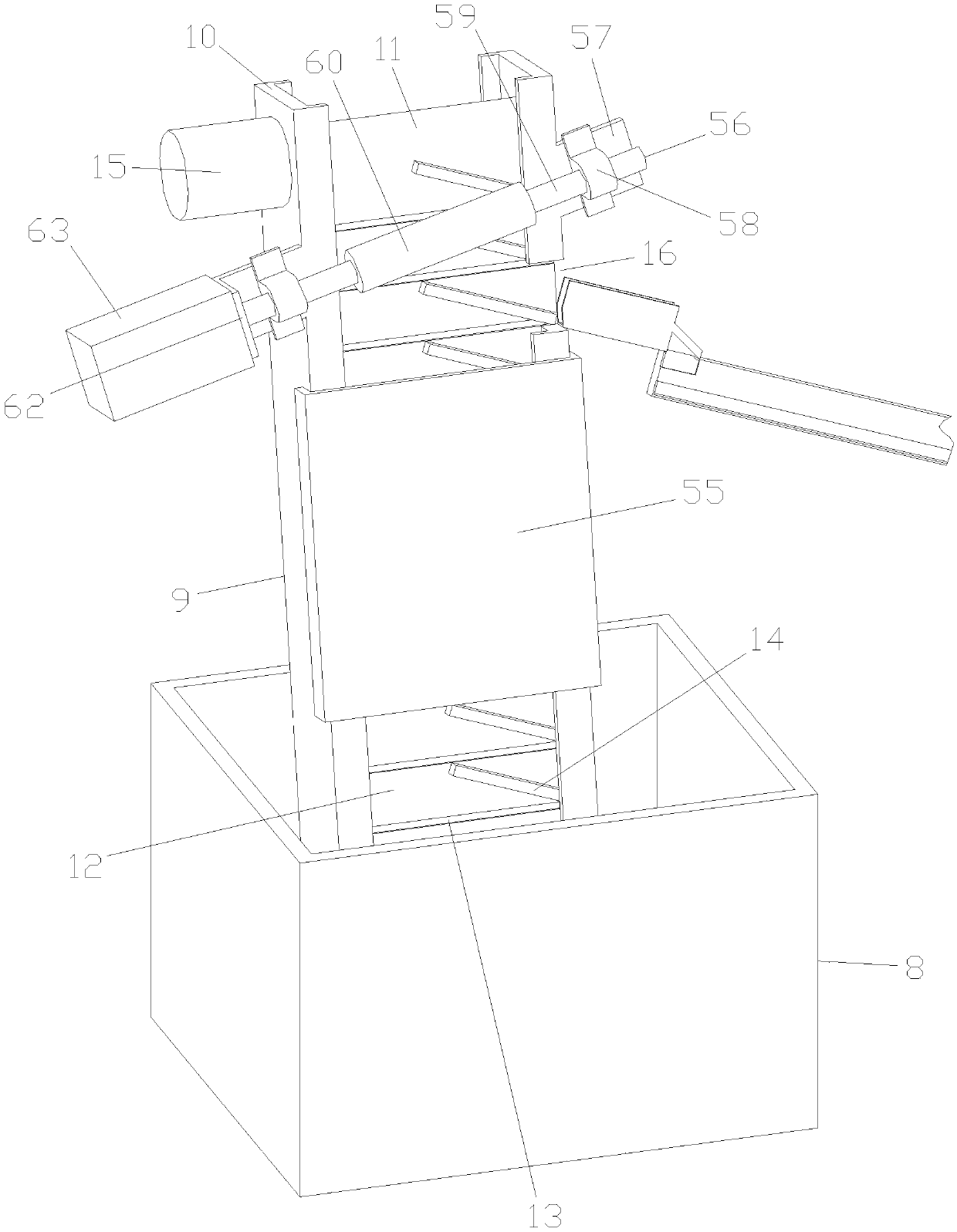

[0034] The vertical conveying unit 3 comprises a container 8 for placing bearings, a vertical and inclined conveying frame 9 is provided in the container 8, the lower end of the conveying frame 9 is placed in the container 8, and the upper end of the conveying frame 9 is placed outside the container 8. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com