Condensation crystallization device and method

A technology of crystallization equipment and crystal nucleus, which is applied in the field of chemical equipment, can solve the problems of small crystal particle size, easy blockage of pipelines, easy wall formation, and agglomeration, so as to avoid crystallization and scaling, ensure stable and continuous operation, and ensure stable and continuous operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

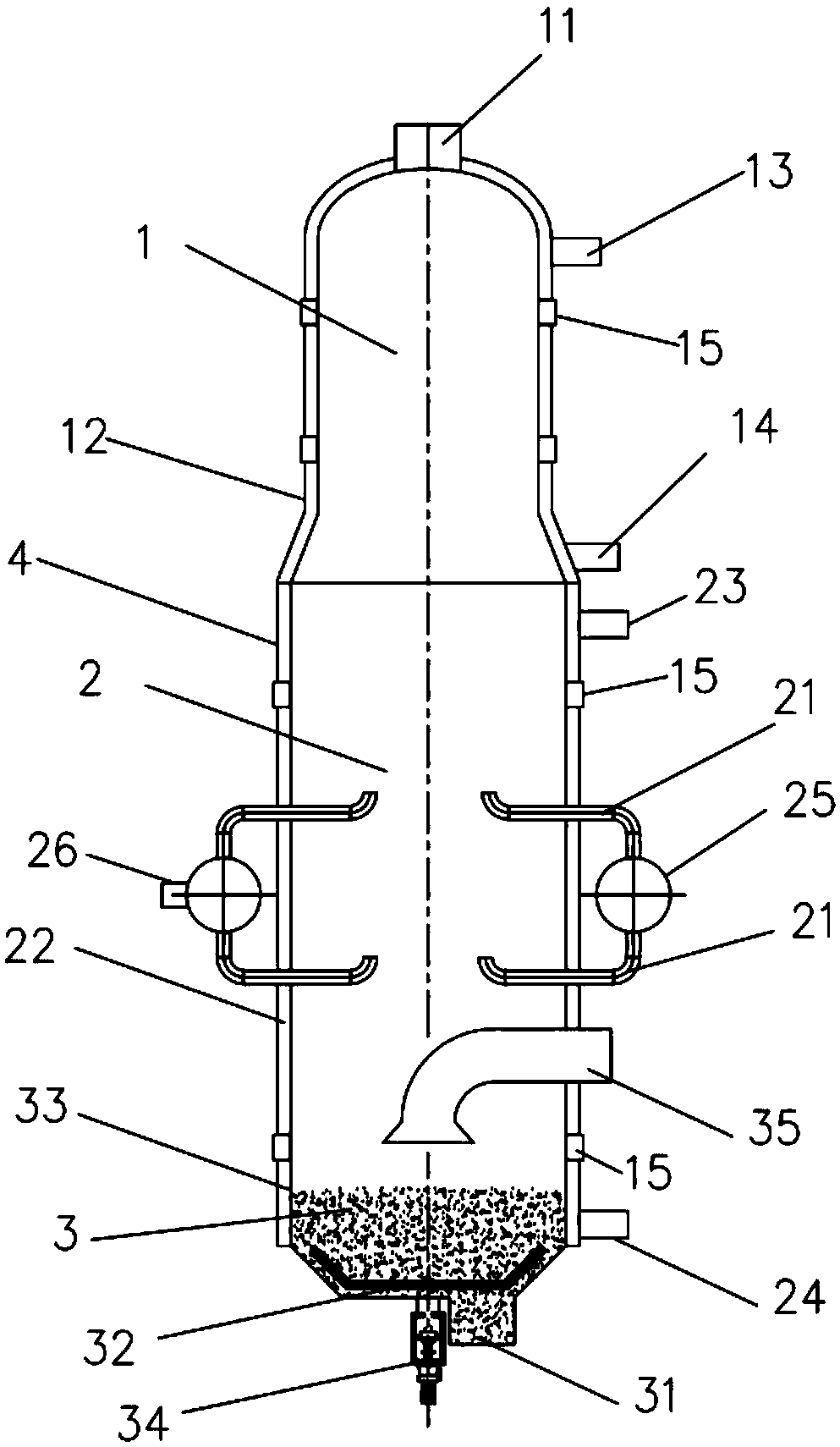

[0043] This embodiment provides a crystal desublimation equipment, such as figure 1 As shown, it includes: a cylinder 4, and the cylinder 4 is divided into:

[0044] The crystal nucleus forming section 1 is provided with a process gas inlet 11 on the top and a first heat preservation structure 12 on the outside;

[0045] The crystal growth section 2 is provided with several cold air intake pipes 21, and a second heat preservation structure 22 is provided outside;

[0046] The discharge section 3 is provided with a solid discharge port 31 and a rotating part 32 at the bottom, the rotating part 32 drives the crystallized solid material to the solid discharge port 31 for discharge, and the discharge section 3 is provided with a gas discharge port 35 , a third thermal insulation structure 33 is arranged on the outside. In this embodiment, the gas outlet is a discharge pipe extending into the center of the discharge section 3 .

[0047] The above-mentioned crystallization desubl...

Embodiment 2

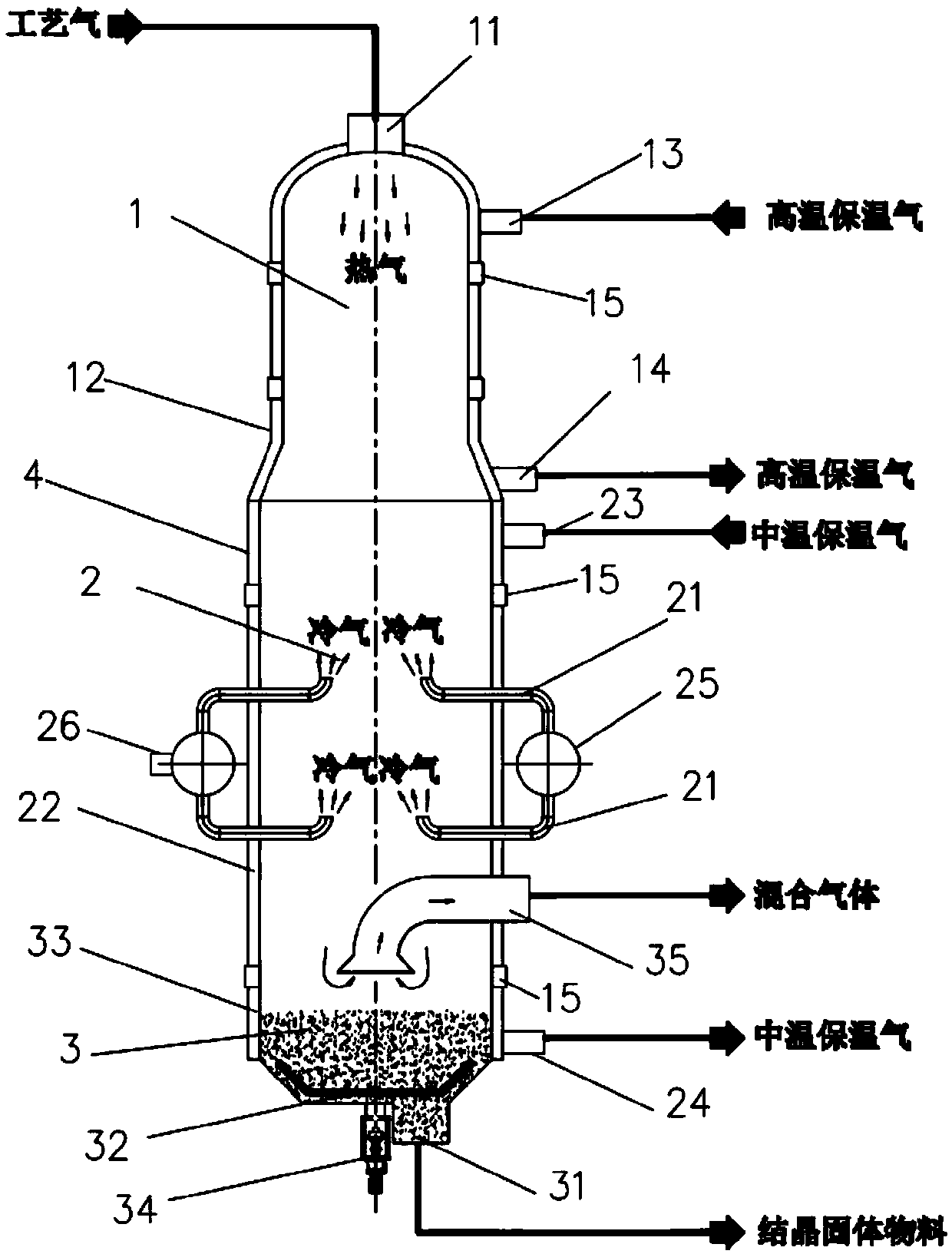

[0054] This embodiment provides a method for sublimation crystallization, such as figure 2 As shown, the practical application in the production of melamine is taken as an example to illustrate, including the following steps:

[0055] Crystal nucleation stage: high temperature gas containing melamine material (the main components are melamine, ammonia and CO 2 ) from the process gas inlet 11 at the top of the desublimation crystallization equipment cylinder body 4 to the crystal nucleus formation section 1, and a small amount of cold air from the crystal growth section 2 (the main components are ammonia and CO 2 ) for mixing. The pressure inside the sublimation crystallizer is 0.3MPa, and the melting point temperature of melamine under this pressure is 300°C. Gu controls the temperature in this section to be 270-300°C. At this time, the gas phase material begins to crystallize and form a small amount of crystal nuclei; the temperature in this section cannot Too low to avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com