A kind of all-aluminum back field back silver paste and its preparation method and application

一种背银浆料、全铝背场的技术,应用在太阳能电池领域,能够解决增加背电极宽度、增加背电极浆料成本、降低太阳能电池光电转换效率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] An all-aluminum back-field back-silver paste, said all-aluminum back-field back-silver paste includes the following in parts by weight: 10-80 parts of special-required silver powder with a purity greater than 99.99%, 0.5-80 parts of homemade lead-free main glass powder 5 parts, 0-3 parts of low melting point auxiliary glass powder, 1-50 parts of low melting point metal powder for special requirements, 15-50 parts of organic binder, and 0.01-1 part of organic auxiliary agent.

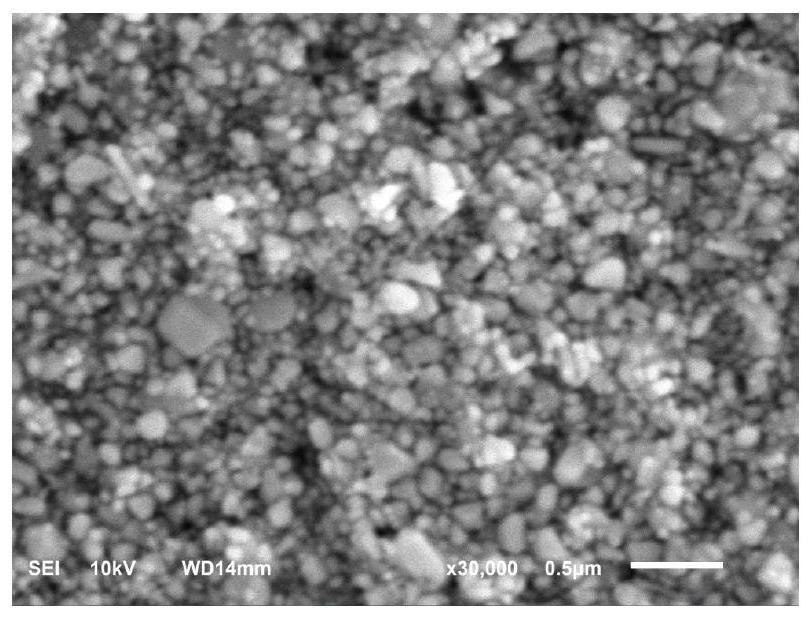

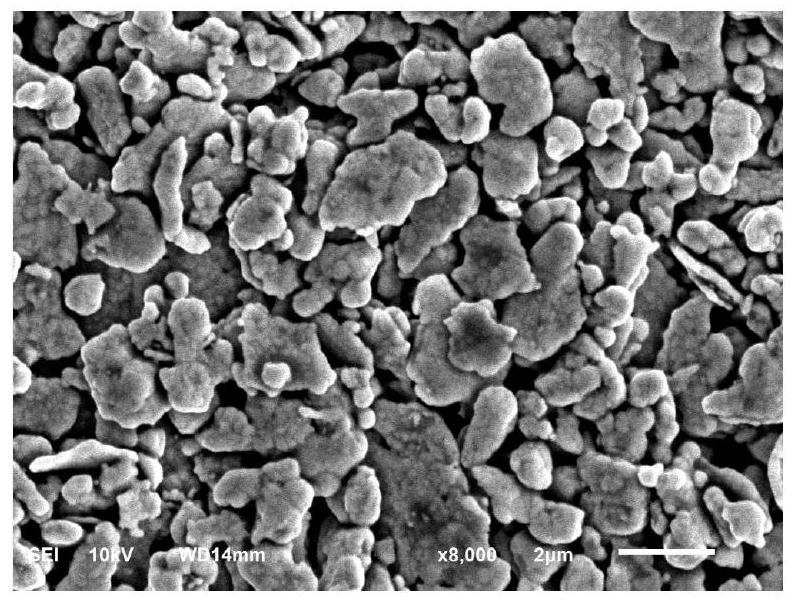

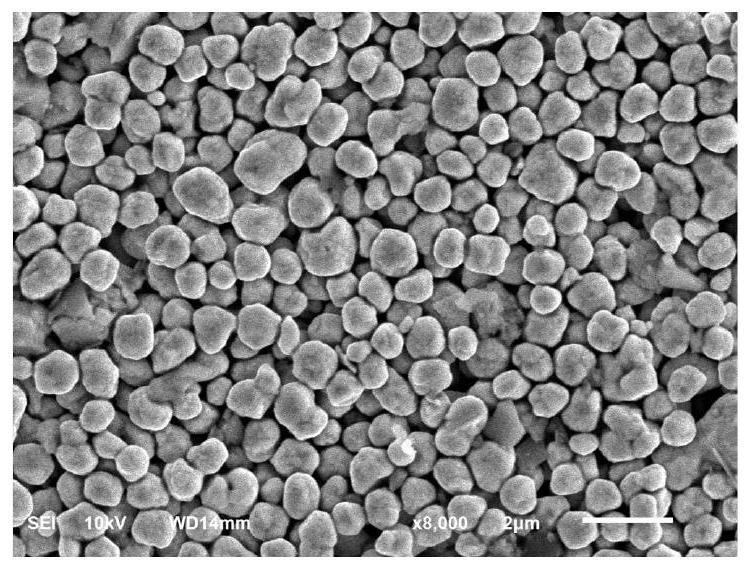

[0037] The special requirement silver powder is spherical silver powder, hollow spherical silver powder, flaky silver powder or ultrafine silver powder, and the particle size D50 of the spherical silver powder is 1-13 μm; the particle size D50 of the hollow spherical silver powder is 3-20 μm; the flaky silver powder The diameter D50 is 2-30μm; the ultra-fine silver powder particle size D50 is 0.1-3μm, and the specific surface area is 1.5-5m 2 / g.

[0038] The spherical silver powder has a particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com