Cooling equipment for special type copper rod smelting forming

A technology of cooling equipment and copper rods, applied in heat treatment equipment, furnace types, furnaces, etc., can solve the problem that the contact surface cannot be cooled synchronously, and achieve the effect of increasing the contact surface and reducing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

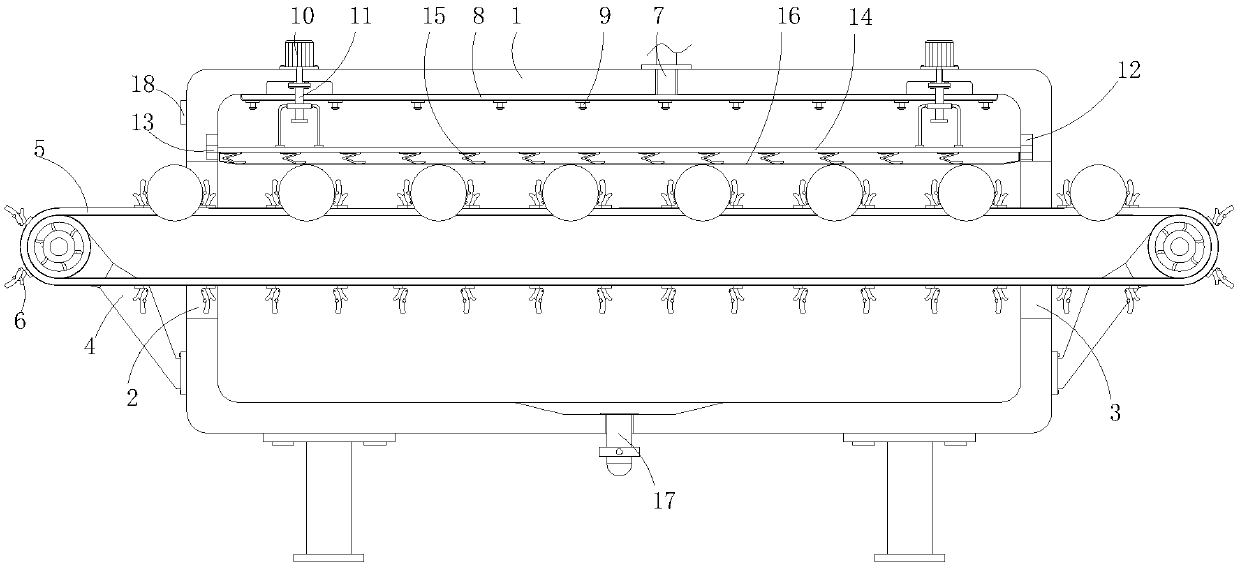

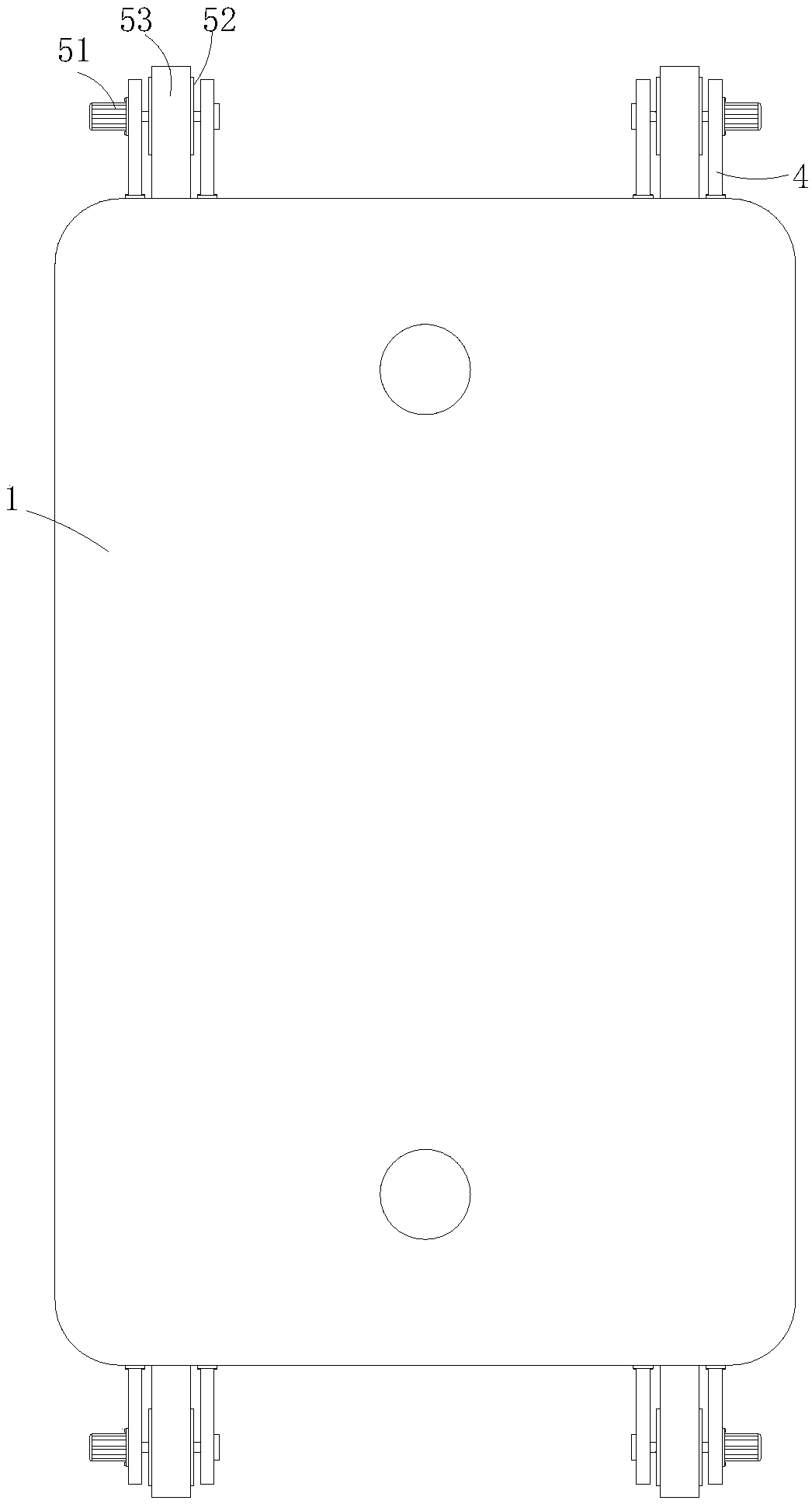

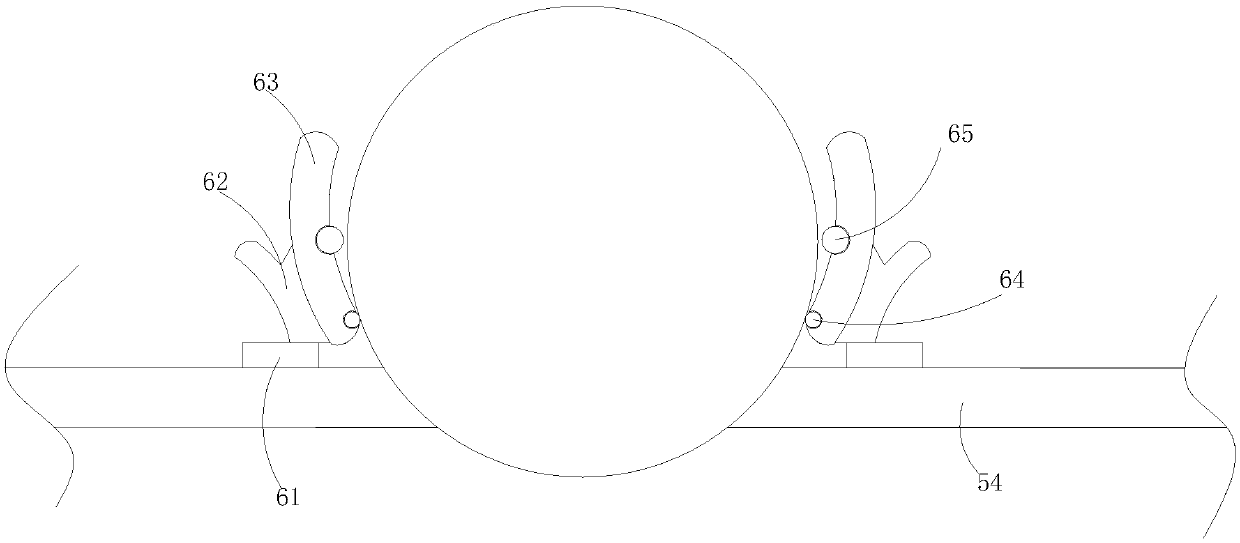

[0024] Such as Figure 1-6As shown, the present invention provides a technical solution: a cooling equipment for special copper rod smelting and forming, including a body 1, an inlet 2, an outlet 3, two sets of fixing frames 4, two sets of transmission mechanisms 5, and eighteen sets of positioning Mechanism 6, water guide joint 7, horizontal multi-way pipe 8, nine nozzles 9, two low-speed motors 10, two pressure adjustment mechanisms 11, two vertical chute 12, two vertical movable blocks 13, horizontal mounting plate 14 , thirteen elastic pressure parts 15, high temperature resistant fiber cloth 16, drain pipe 17 and control panel 18, the inlet 2 and the outlet 3 are set on the left and right sides of the body 1 respectively, and the two sets of fixing frames 4 are respectively fixed and installed by bolts At the inlet 2 and the outlet 3 on the left and right sides of the body 1, two sets of transmission mechanisms 5 are respectively connected through two sets of fixing frame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com