Preparation method and application of tar-based carbon quantum dots

A tar-based carbon and quantum dot technology, applied in chemical instruments and methods, measuring devices, nanotechnology, etc., can solve problems such as high requirements and inability to detect quickly, and achieve high sensitivity, meet the requirements of offshore operations, and take up less land. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

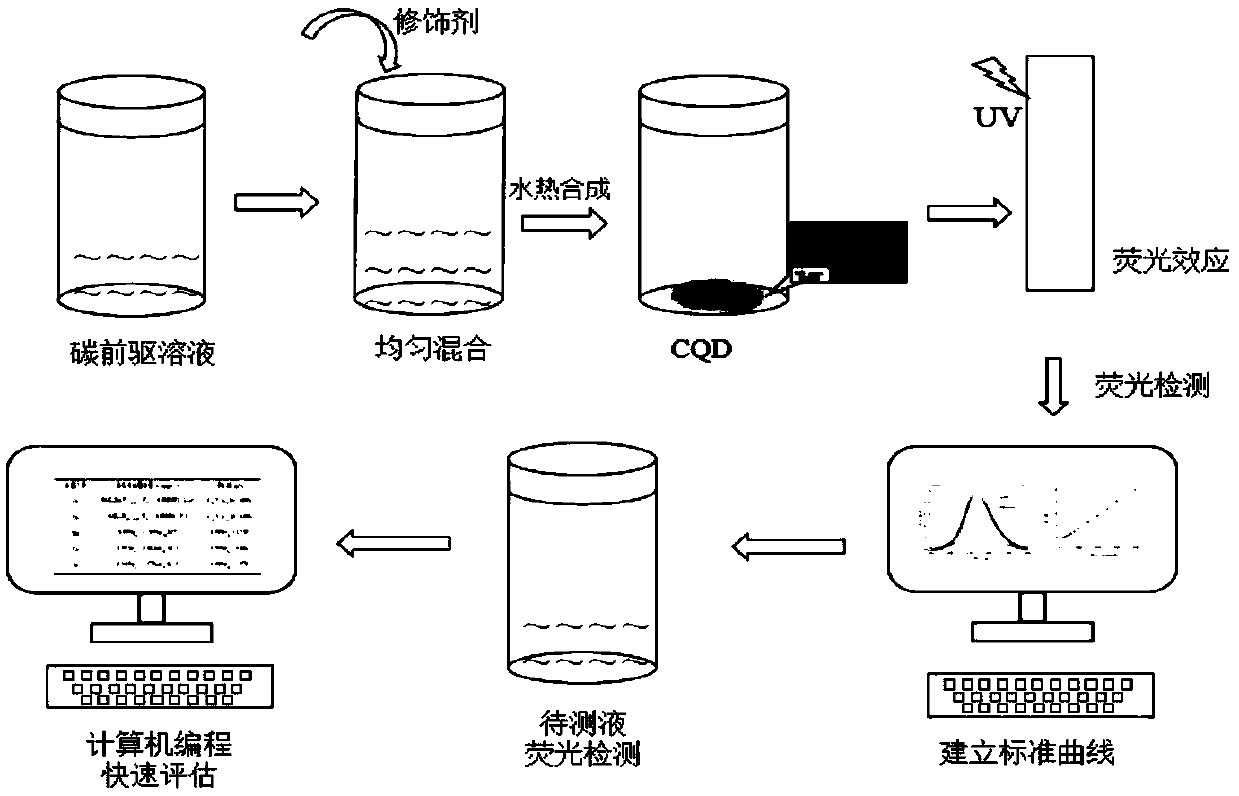

[0044] The invention provides a preparation method and application of tar-based carbon quantum dots, such as figure 2 shown.

[0045] The preparation method comprises steps as follows:

[0046] (1) The biomass tar is rotatably distilled at 100°C-200°C, the fractions are collected, and prepared into an aqueous solution of biomass tar with a mass fraction of 10%-30%, and a certain volume of nitrogen-containing small molecules with a concentration of 0.1-1g / mL is added solution, mix well;

[0047] (2) Transfer the homogeneously mixed solution in step (1) to a reaction kettle with a polytetrafluoroethylene liner. After ultrasonic treatment in a mechanical ultrasonic cleaner for 5 to 15 minutes, put it into a muffle furnace and heat it at 160°C to 220°C. Keep warm at ℃ for 0.5h~2h, then cool down to room temperature naturally;

[0048] (3) Filter the solution obtained in step (2) with a 0.22 μm microporous membrane, then dialyze in a dialysis bag with a molecular weight of 3500...

Embodiment 1

[0066] The biomass tar was rotary distilled at 150°C, the fractions were collected, and configured into a tar aqueous solution with a mass fraction of 15%. Take 10mL of the above tar aqueous solution and 1mL of a concentration of 0.5g / mL polyethyleneimine solution, mix well, and transfer to 50mL polytetrafluoroethylene Put it in an ethylene reaction kettle, put it in a muffle furnace, keep it at 180°C for 1.5h, take it out, and cool it to room temperature. Filter the obtained brown-yellow solution with a 0.22 μm microporous membrane, and then dialyze it in a dialysis bag with a molecular weight of 3500 Da for 24 hours. The yield reached 27.6%.

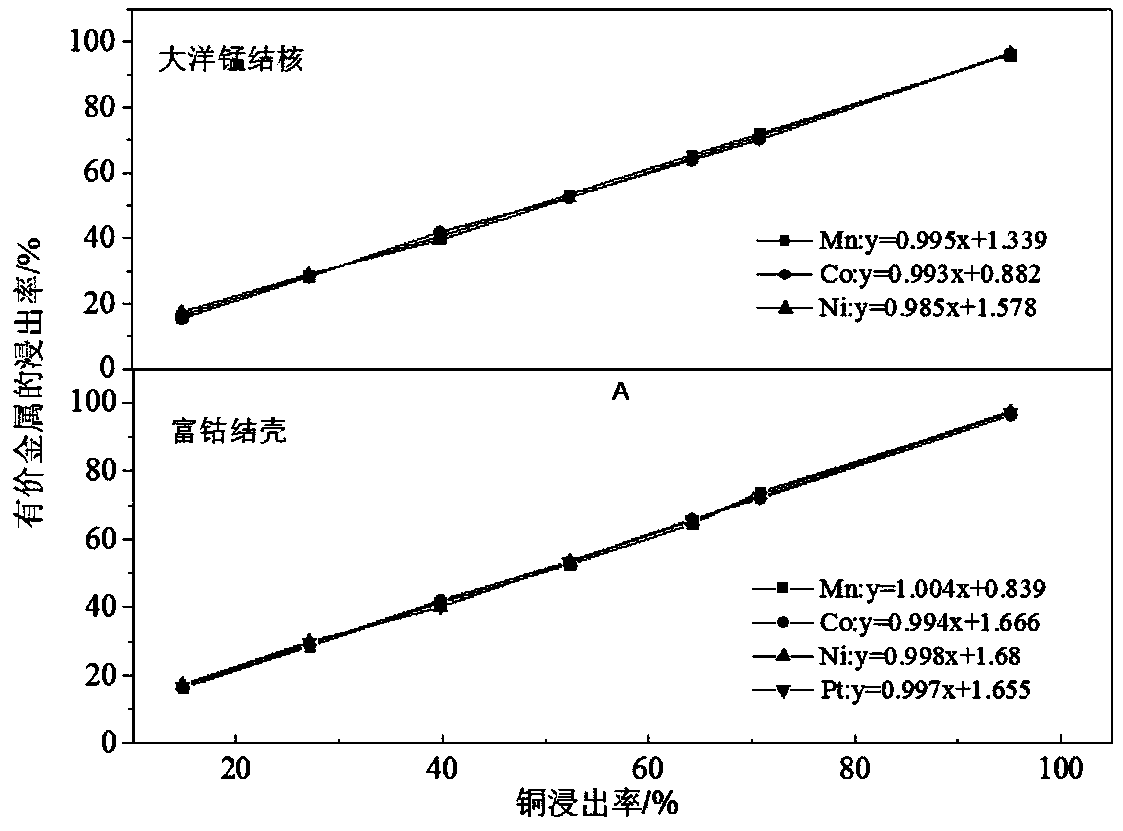

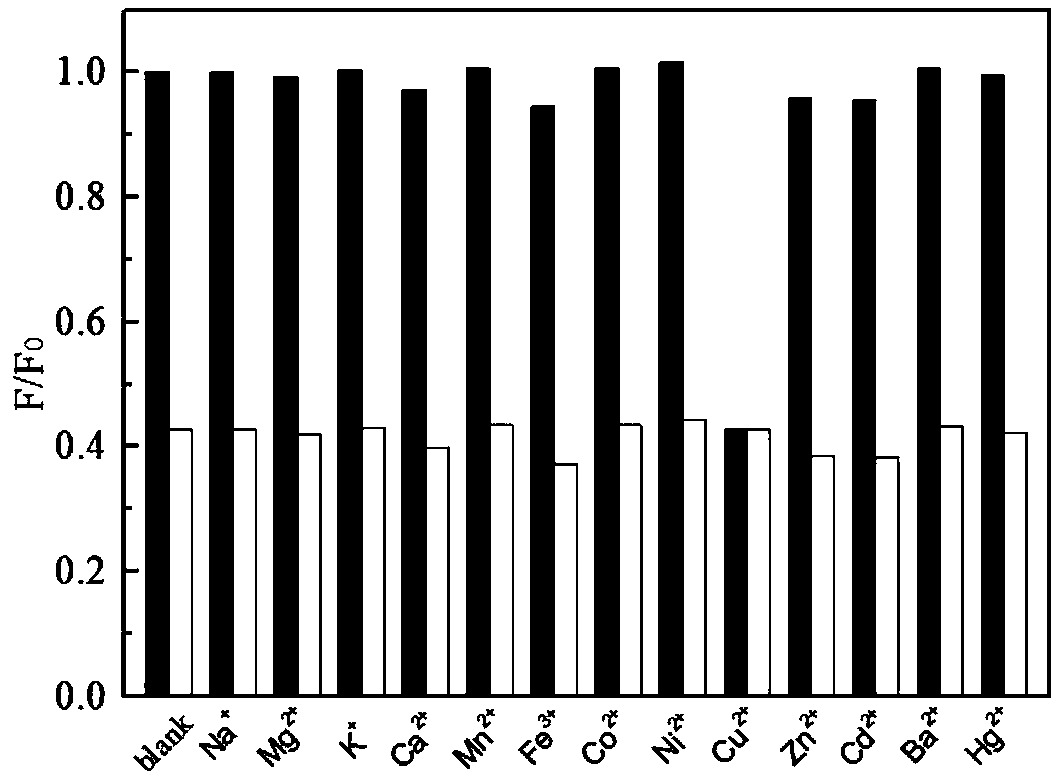

[0067] image 3 For adding Cu 2+ Before and after different metal ions on the above PEI-CQDs fluorescence intensity diagram, in the presence of different metal ions, adding the same amount of Cu 2+ (white), F / F 0 The values are all decreased, indicating that the addition of Cu 2+ Afterwards, PEI-CQDs all had a strong quenching e...

Embodiment 2

[0071] The biomass tar was rotatively distilled at 180°C, the fractions were collected, and configured into a tar aqueous solution with a mass fraction of 10%. Take 10mL of the above tar aqueous solution and 1.5mL of a concentration of 0.3g / mL ethylenediamine solution, mix well, and transfer to 50mL polytetrafluoroethylene Put it in an ethylene reactor, put it in a muffle furnace, keep it at 200°C for 1 hour, take it out, and cool it to room temperature. The obtained brown-yellow solution was filtered with a 0.22 μm microporous membrane, and then dialyzed in a dialysis bag with a molecular weight of 3500 Da for 24 h, and the dialysate was vacuum-dried at 80° C. for 1.5 h to obtain reddish-brown tar-based carbon quantum dots (N-CQDs), which The fluorescence yield is up to 31.4%.

[0072] Figure 6 It is the fluorescence quenching effect of different metal ions on N-CQDs (black), it can be seen that only Fe 3+ Can significantly quench the fluorescence intensity of N-CQDs, F / F ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com