PA6/AES composite material and preparation method thereof

A technology of composite materials and small molecules, which is applied in the field of PA6/AES composite materials and its preparation, can solve the problems of insufficient low-temperature toughness, poor weather resistance, and difficulty in direct use, so as to improve impact performance, weather resistance, and thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

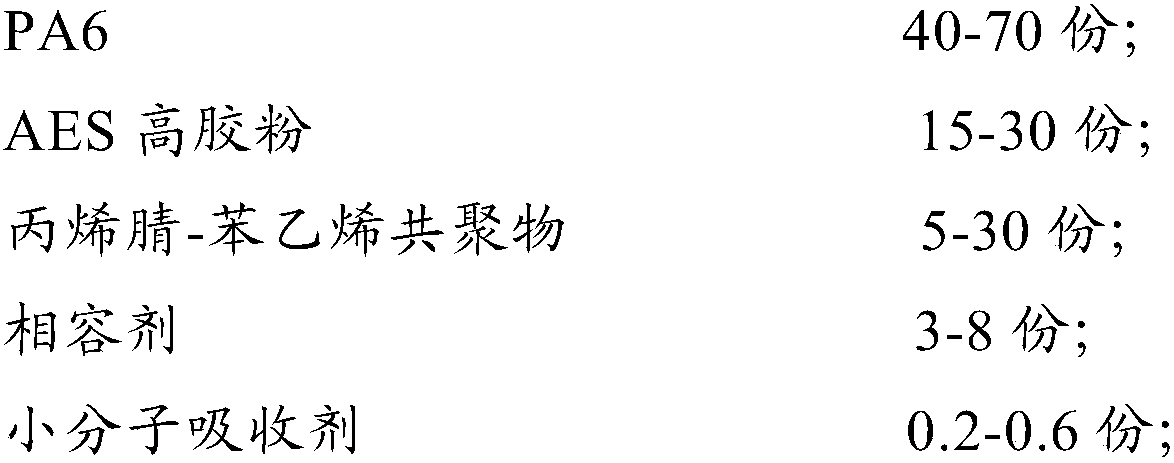

Method used

Image

Examples

preparation example Construction

[0040] The present disclosure also provides a preparation method of PA6 / AES composite material, comprising the following steps:

[0041] Step (1): Dry PA6 and compatibilizer at 100°C-120°C for 2-4 hours respectively.

[0042] Step (2): Weigh quantitative PA6, acrylonitrile-styrene copolymer, AES high rubber powder, compatibilizer, small molecule absorbent, antioxidant and lubricant, and mix in a high mixer for 2-5min, The rotating speed is 400-1000rpm to obtain the mixed material.

[0043] Step (3): Send the mixture into a twin-screw extruder, and obtain the PA6 / AES composite material after melting, extrusion, water cooling, air drying and pelletizing.

[0044] Step (3) can specifically be:

[0045] Put the mixture obtained in step (2) into the hopper of a twin-screw extruder and extrude to pelletize. The twin-screw extruder includes seven temperature zones arranged in sequence, and the temperature in one zone is 200-220 ℃, the temperature in the second zone is 250-270 ℃, t...

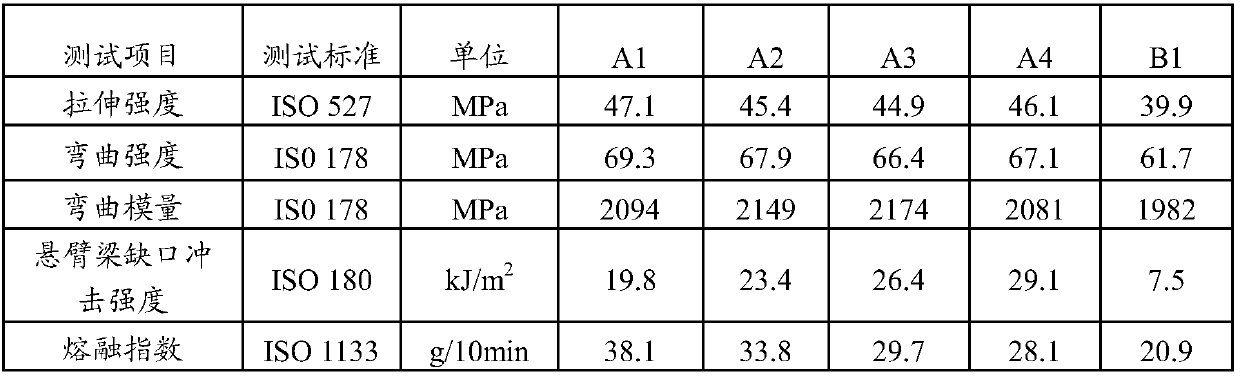

Embodiment 1

[0049](1) Weigh 64 parts of dried PA6, 18 parts of AES high rubber powder, 15 parts of SAN resin, 3 parts of dried compatibilizer, 0.3 part of zeolite powder, 0.1 part of antioxidant 1098, 0.2 part of antioxidant 627A, 0.2 lubricant PETS were mixed and stirred evenly to obtain a mixture;

[0050] (2) Extrude and granulate the mixture obtained in step (1) to obtain PA6 / AES composite material A1, wherein the temperature in each zone of the twin-screw extruder and the screw speed are respectively: the temperature in the first zone is 205 ° C, and the temperature in the second zone is 205 ° C. 250°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 240°C, the temperature of the sixth zone is 240°C, the temperature of the head is 225°C, and the screw speed is 280r / min.

Embodiment 2

[0052] (1) Weigh 53 parts of dried PA6, 22 parts of AES high rubber powder, 20 parts of SAN resin, 5 parts of dried compatibilizer, 0.3 part of zeolite powder, 0.2 part of antioxidant 1098, 0.2 part of antioxidant 627A, 0.4 parts of lubricant PETS are mixed and stirred evenly to obtain a mixture;

[0053] (2) Extrude and granulate the mixture obtained in step (1) to obtain PA6 / AES composite material A2, wherein the temperature in each zone of the twin-screw extruder and the screw speed are respectively: the temperature in the first zone is 215 ° C, the temperature in the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 250°C, the temperature of the sixth zone is 250°C, the temperature of the head is 235°C, and the screw speed is 350r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com