Method for preparing cotton swab stick material from montmorillonite-composite modified straw fiber powder-polylactic acid

A technology of straw fiber powder and composite modification, applied in the field of daily necessities, can solve the problems of limited development, poor toughness, poor thermal stability of polylactic acid, etc., achieve good toughening effect, large interlayer distance, and improve thermal stability and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

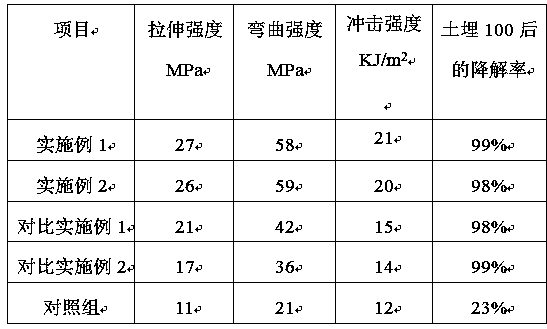

Examples

Embodiment 1

[0021] A method for preparing a cotton swab material with montmorillonite-composite modified straw fiber powder-polylactic acid, characterized in that it comprises the following steps:

[0022] (1) Organicization of sodium montmorillonite:

[0023] Add deionized water to 4 parts of sodium montmorillonite at a ratio of 1:30, stir mechanically for 1 hour, raise the temperature to 70-75°C, add dilute hydrochloric acid solution dropwise to adjust the pH of the suspension to 6; mix 0.5 parts of surfactant and isopropyl Make an aqueous solution of alcohol, add it dropwise to the suspension under stirring, keep it warm for 25 minutes, then ultrasonically react it at 80-85°C for 10 minutes, let it stand to cool down, filter it with suction, and wash it repeatedly with ethanol aqueous solution until there is no bromide ion. Dry to constant weight in a vacuum drying oven at ℃, grind and pass through a 200-mesh sieve to prepare reactive montmorillonite;

[0024] (2) Alkali-coupling agen...

Embodiment 2

[0033] A method for preparing a cotton swab material with montmorillonite-composite modified straw fiber powder-polylactic acid, characterized in that it comprises the following steps:

[0034] (1) Organicization of sodium montmorillonite:

[0035] Add deionized water to 6 parts of sodium montmorillonite at a ratio of 1:35, stir mechanically for 2 hours, raise the temperature to 75°C, add dilute hydrochloric acid solution dropwise to adjust the pH of the suspension to 6; prepare 1 part of surfactant and isopropanol Form an aqueous solution, add it dropwise to the suspension under stirring, keep it warm for 35 minutes, then ultrasonically react at 80-85°C for 15 minutes, let it stand to cool down, filter with suction, wash repeatedly with ethanol aqueous solution until there is no bromide ion, vacuum at 40-50°C Dried in a drying oven to constant weight, ground and passed through a 200-mesh sieve to obtain reactive montmorillonite;

[0036] (2) Alkali-coupling agent composite m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com