Biomass-based grading porous carbon and preparation method thereof

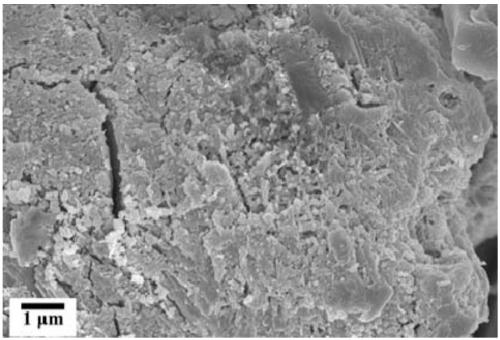

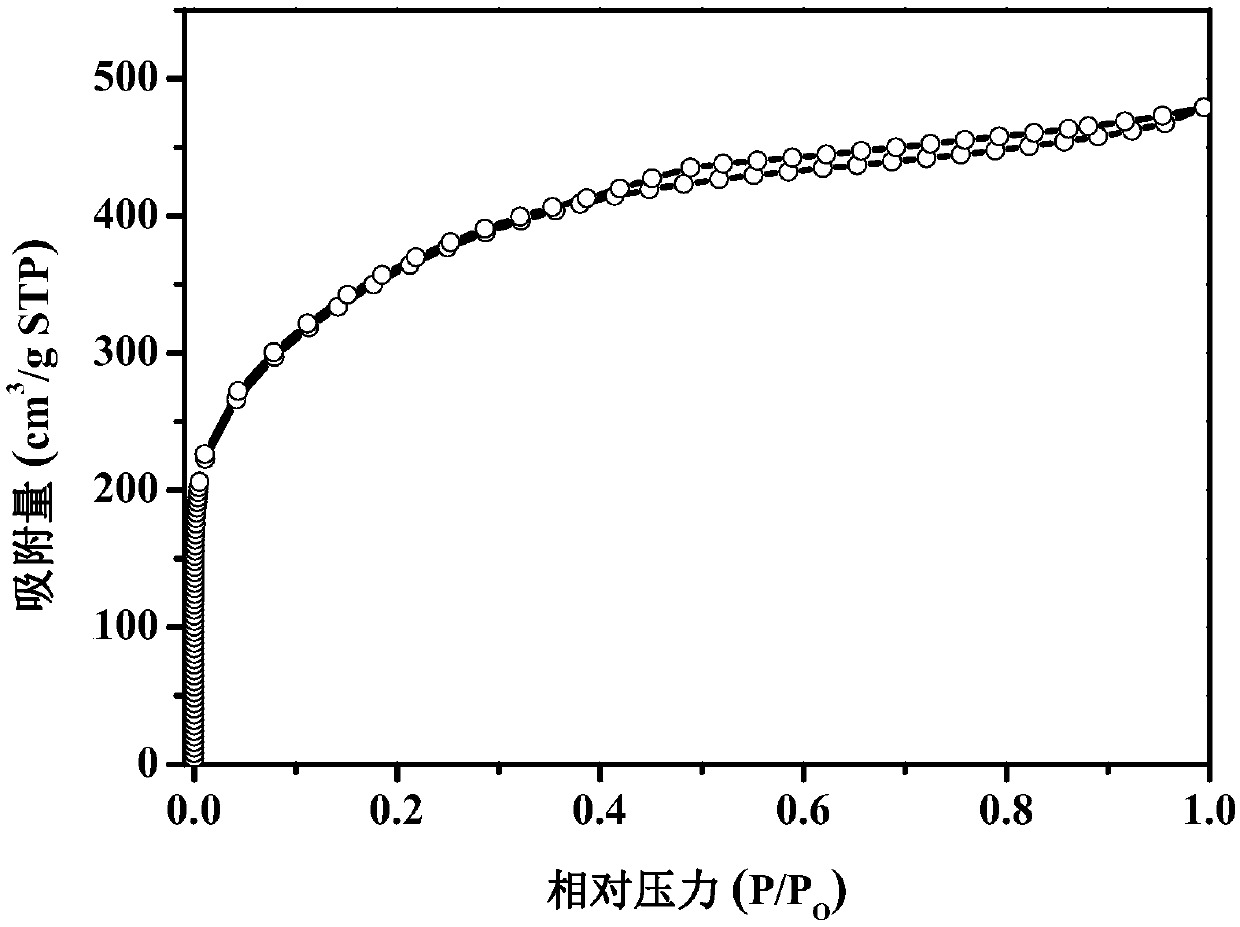

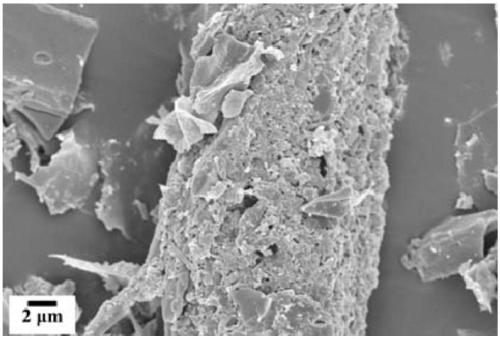

A hierarchically porous, biomass technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as single action, irregular pre-carbonized material morphology, and carbon particles stacked into agglomerates, and achieve loose pore structure. , The effect of improving porosity and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of biomass-based hierarchical porous carbon in this embodiment, the specific preparation steps are as follows:

[0036] (1) Weigh 5 g of rice straw powder that has been sheared and sieved to 20 meshes, and mix the rice straw powder, double-salt system and water at a mass ratio of 1:5:10; among them, potassium chloride (KCl ) and sodium chloride (NaCl) system, the molar ratio of the two is 25:75. Put the above mixture into a high-temperature and high-pressure hydrothermal reactor, seal and heat to 180 °C, and react for 20 h under constant temperature stirring at 100 r / min; after the reaction is completed, cool to room temperature, and wash the solid product in the reactor with deionized water to medium properties, the washed product was dried at 80 °C for 24 h to obtain a pre-carbonized product;

[0037] (2) Weigh 1 g of the pre-carbonized product, mix the pre-carbonized product with potassium hydroxide (KOH) and silicon dioxide (SiO 2 ) was ground...

Embodiment 2

[0039] A preparation method of biomass-based hierarchical porous carbon in this embodiment, the specific preparation steps are as follows:

[0040] (1) Weigh 20 g of corn stalk powder that has been sheared and sieved to 30 meshes, and mix the corn stalk powder, double-salt system and water at a mass ratio of 1:1:1; among them, potassium chloride (KCl ) and zinc chloride (ZnCl 2 ) system, the molar ratio of the two is 40:60. Put the above mixture into a high-temperature and high-pressure hydrothermal reactor, seal and heat to 300 °C, and react for 5 h under constant temperature stirring at 200 r / min; after the reaction is completed, cool to room temperature, and wash the solid product in the reactor with deionized water to medium properties, the washed product was dried at 80 °C for 24 h to obtain a pre-carbonized product;

[0041] (2) Weigh 10 g of the pre-carbonized product, mix the pre-carbonized product with potassium oxalate (K 2 C 2 o 4 ) and calcium carbonate (CaCO ...

Embodiment 3

[0043] A preparation method of biomass-based hierarchical porous carbon in this embodiment, the specific preparation steps are as follows:

[0044] (1) Weigh 12 g of peanut shell powder that has been sheared and sieved to 50 mesh, and mix the peanut shell powder, double-salt system and water at a mass ratio of 1:5:1; among them, aluminum chloride (AlCl 3 ) and sodium chloride (NaCl) system, the molar ratio of the two is 25:75. Put the above mixture into a high-temperature and high-pressure hydrothermal reactor, seal and heat to 180 °C, and react for 20 h under constant temperature stirring at 100 r / min; after the reaction is completed, cool to room temperature, and wash the solid product in the reactor with deionized water to medium properties, the washed product was dried at 80 °C for 24 h to obtain a pre-carbonized product;

[0045] (2) Weigh 8 g of the pre-carbonized product, mix the pre-carbonized product with potassium bicarbonate (KHCO 3 ) and alumina (Al 2 o 3 ) was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com