Glass detergent and preparation method thereof

A technology of glass cleaning agent and decontamination agent, which is applied in the preparation of detergent mixture composition, detergent composition, detergent compounding agent, etc., and can solve the problems of poor cleaning effect of oily cutting fluid, bluish glass surface, damage Glass surface and other problems, achieve good decontamination ability, good decontamination effect, and reduce the effect of secondary adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

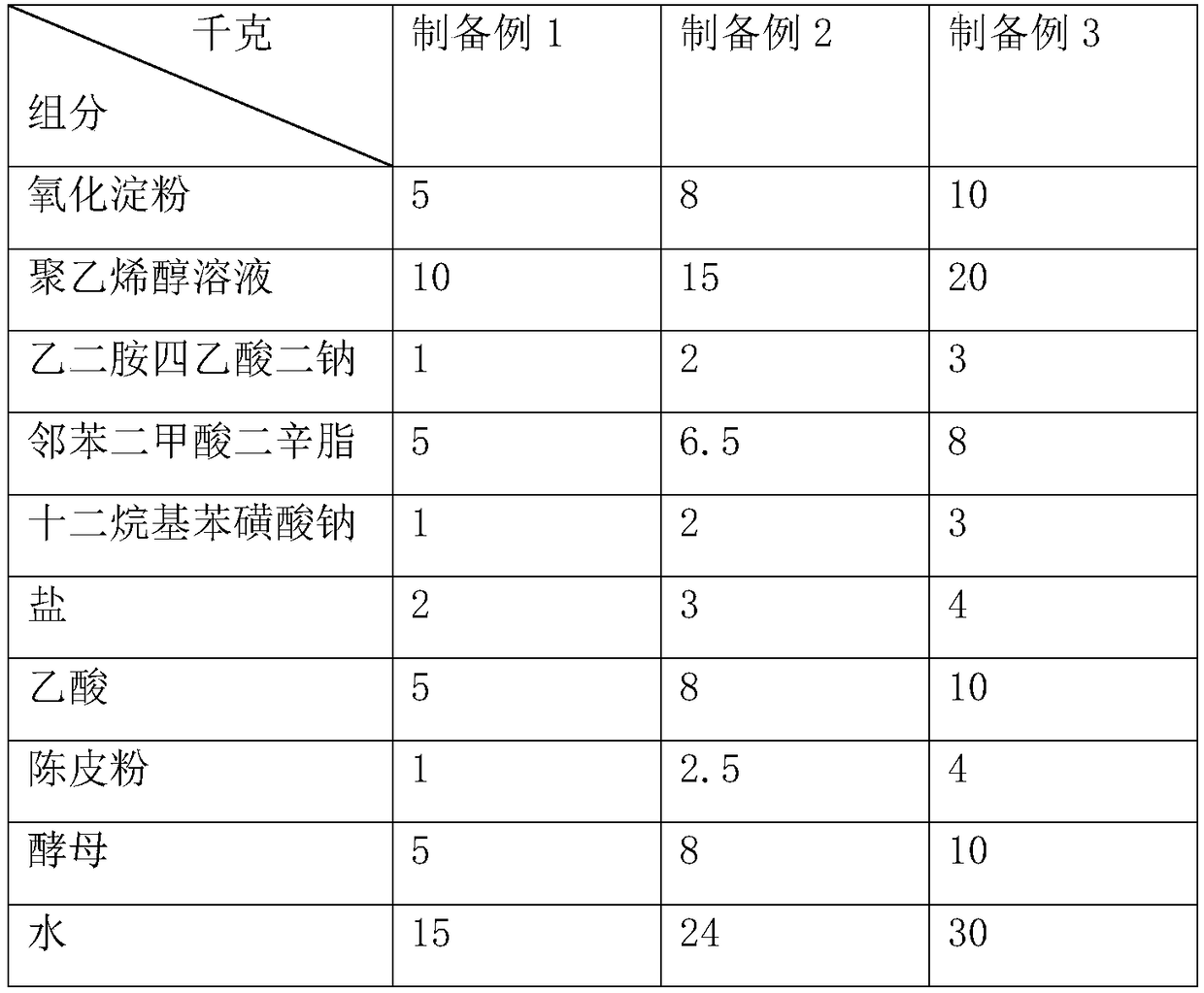

[0033] In Preparation Example 1-3, disodium edetate was selected from DG-73434 disodium edetate sold by Guangzhou Dongge Chemical Technology Co., Ltd., and dioctyl phthalate was selected from Rongbei (Shanghai) Co., Ltd. The DOP type dioctyl phthalate and sodium dodecylbenzene sulfonate sold by Chemical Technology Co., Ltd. are selected from the model 60 sodium dodecylbenzene sulfonate sold by Jinnan Yaohui Chemical Co., Ltd., and the selection of tangerine peel powder The tangerine peel powder sold by Bozhou Huabao Pharmaceutical Co., Ltd. is CP, the yeast is selected from the yeast sold by Shandong Kangqin Biotechnology Cable Co., Ltd., and the product number sold by Hubei Guihezheng Trading Co., Ltd. is 284. The industrial salt of 02, the acetic acid is selected from the acetic acid whose article number is selected from 101405 sold by Zhengzhou Laikai Biotechnology Co., Ltd.

preparation example 1

[0034] Preparation Example 1: (1) According to the ratio in Table 1, heat 10kg of polyvinyl alcohol solution in a water bath at 80°C for 1min, add 5kg of oxidized starch while stirring, stir at a speed of 1000r / min for 1h, and then add 1kg disodium edetate, 5kg dioctyl phthalate and 1kg sodium dodecylbenzenesulfonate, stirred at 500r / min for 1h;

[0035] (2) Dissolve 5 kg of acetic acid in 15 kg of water to form an acetic acid solution, dissolve 2 kg of salt in the acetic acid solution, put 1 kg of tangerine peel powder and 5 kg of yeast into the acetic acid, mix well, add the result of step (1), and mix well , that is, the detergent is prepared.

[0036] The raw material ratio of detergent in table 1 preparation example 1-3

[0037]

preparation example 2

[0038] Preparation Example 2: According to the ratio in Table 1, heat 15kg of polyvinyl alcohol solution in a water bath at 85°C for 3 minutes, add 8kg of oxidized starch while stirring, stir at a speed of 1250r / min for 1.5h, and then add 2kg of ethyl alcohol in turn. Disodium diamine tetraacetate, 6.5kg dioctyl phthalate and 2kg sodium dodecylbenzene sulfonate were stirred for 1.5h at a speed of 650r / min;

[0039] (2) 8kg of acetic acid is dissolved in 24kg of water to form an acetic acid solution, 3kg of salt is dissolved in the acetic acid solution, 2.5kg of tangerine peel powder and 8kg of yeast are put into acetic acid, after mixing evenly, add in the step (1) gain, mix Evenly, the detergent is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com